Soybean protein fiber bleaching composition and bleacing method thereof

A technology for soybean protein fiber and composition, applied in the field of bleaching compositions, can solve the problems of difficult control of bleaching process, breakage of peptide bonds of soybean protein, influence on bleaching effect, etc., and achieves broad application prospects, protection of health and health care, and improvement of bleaching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

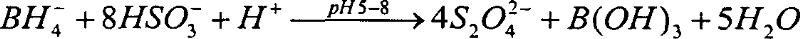

Method used

Image

Examples

Embodiment 1

[0025] Mix 2g of sodium borohydride and 3.86g of sodium bisulfite in the feeding tank, then add 80ml of distilled water to dilute, and then add 12ml of pre-prepared hydrogen peroxide and thiourea compound with a concentration of 50g / L, hydrogen peroxide and thiourea The molar ratio is 1:1, and then add 5mL of penetrant JFC with a concentration of 20g / L, adjust the pH of the bleaching solution to about 10 with sodium bicarbonate, heat the bleaching solution to 50°C, put it into the fabric, and then continue to heat up to 90°C , Keep for 20min, take it out, wash with 1g / L acetic acid aqueous solution, wash with warm water, and dry.

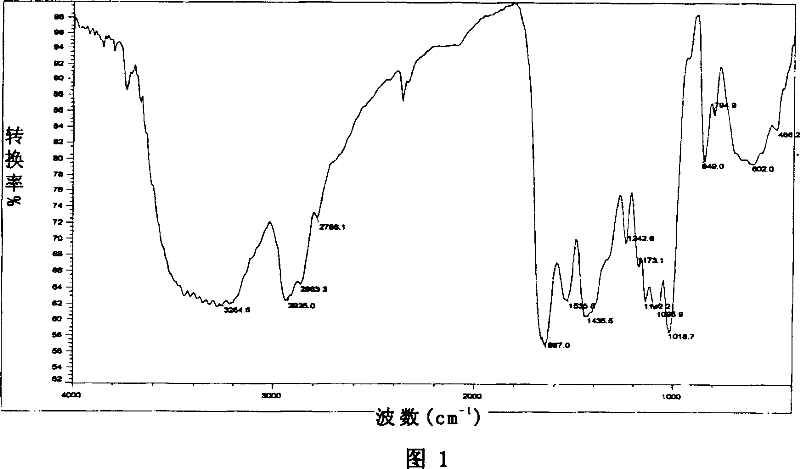

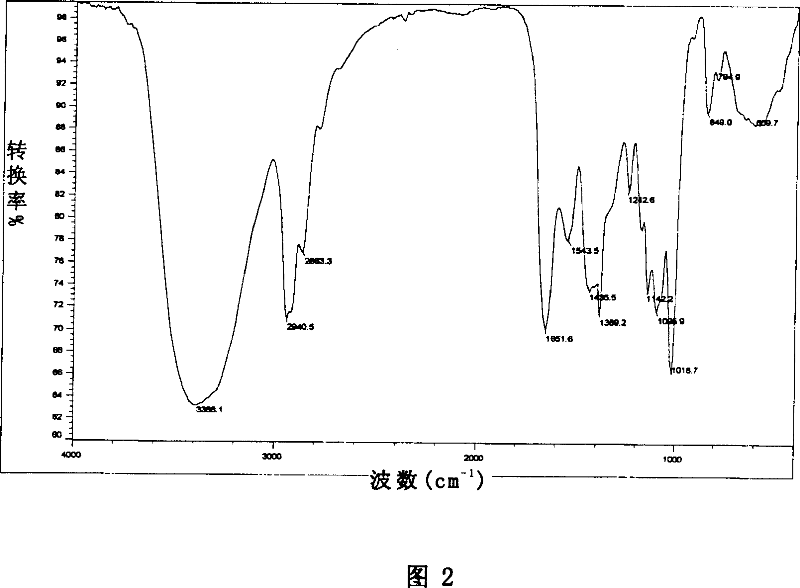

[0026] Refer to Figure 1, which is the infrared absorption spectrum of the fiber measured before using the soybean protein fiber bleaching method of the present invention; refer to Figure 2, which is the infrared absorption spectrum of the fiber measured after the soybean protein fiber bleaching method described above Figure: The test uses Nicolet's Mag...

Embodiment 2

[0033]Add 2g of sodium borohydride to an 80mL water bath containing 3.86g of sodium bisulfite and fabric, and then add 12mL of a pre-prepared hydrogen peroxide and thiourea compound with a concentration of 50g / L, the molar ratio of which is 1:1, Add 5mL of JFC penetrant with a concentration of 20g / L, adjust the pH of the bleaching solution to about 9 with sodium bicarbonate, heat the bleaching solution to 90℃, keep it for 20min, take it out, wash with 1g / L acetic acid aqueous solution, and wash with warm water. Let dry. The whiteness of the fabric after bleaching was 80.2. This shows that the addition of borohydride and sodium bisulfite is more flexible and can be determined according to specific conditions.

Embodiment 3

[0035] Add 2g of sodium borohydride to an 80mL water bath containing 3.86g of sodium bisulfite and fabric, and then add 12mL of a pre-prepared hydrogen peroxide and thiourea compound with a concentration of 50g / L, the molar ratio of which is 1:1. Add 1g / L penetrant JFC, adjust the pH of the bleaching solution to about 9.5 with sodium bicarbonate, heat the bleaching solution to 70°C, keep it for 60min, take it out, wash with 1g / L acetic acid solution, wash with warm water, and dry. The whiteness of the fabric after bleaching was 79.6. In the case of low requirements for bleaching, the bleaching composition can be used for low-temperature slow bleaching to save energy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com