Pressure-difference valve unit, hydraulic control system and engineering machinery

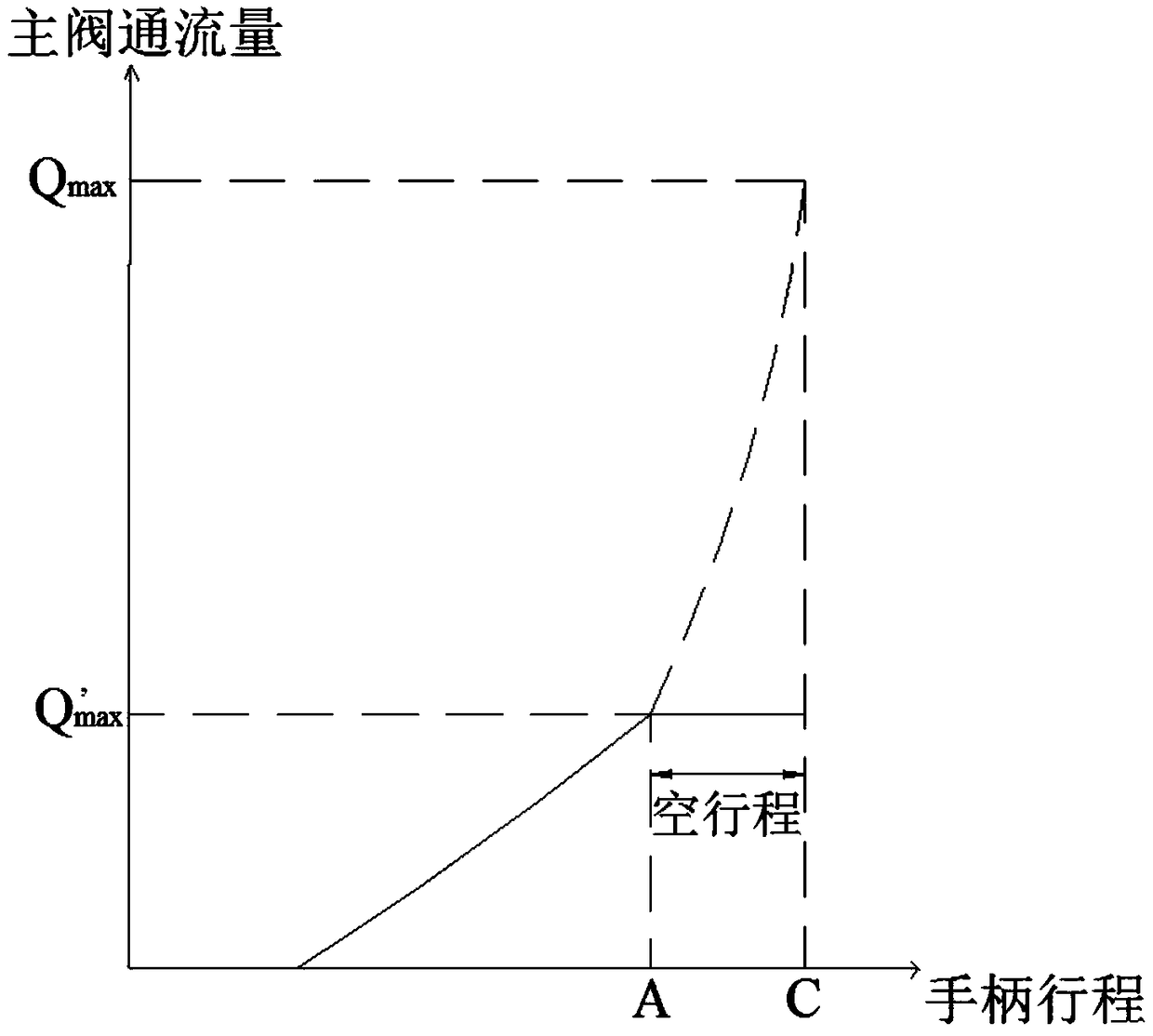

A hydraulic control system and engineering machinery technology, applied in the hydraulic field, can solve problems such as the narrowing of the controllable range, affecting the speed regulation of the system, and the deterioration of the control performance, so as to achieve good micro-movement, small flow adjustment gain, and flow adjustment big gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

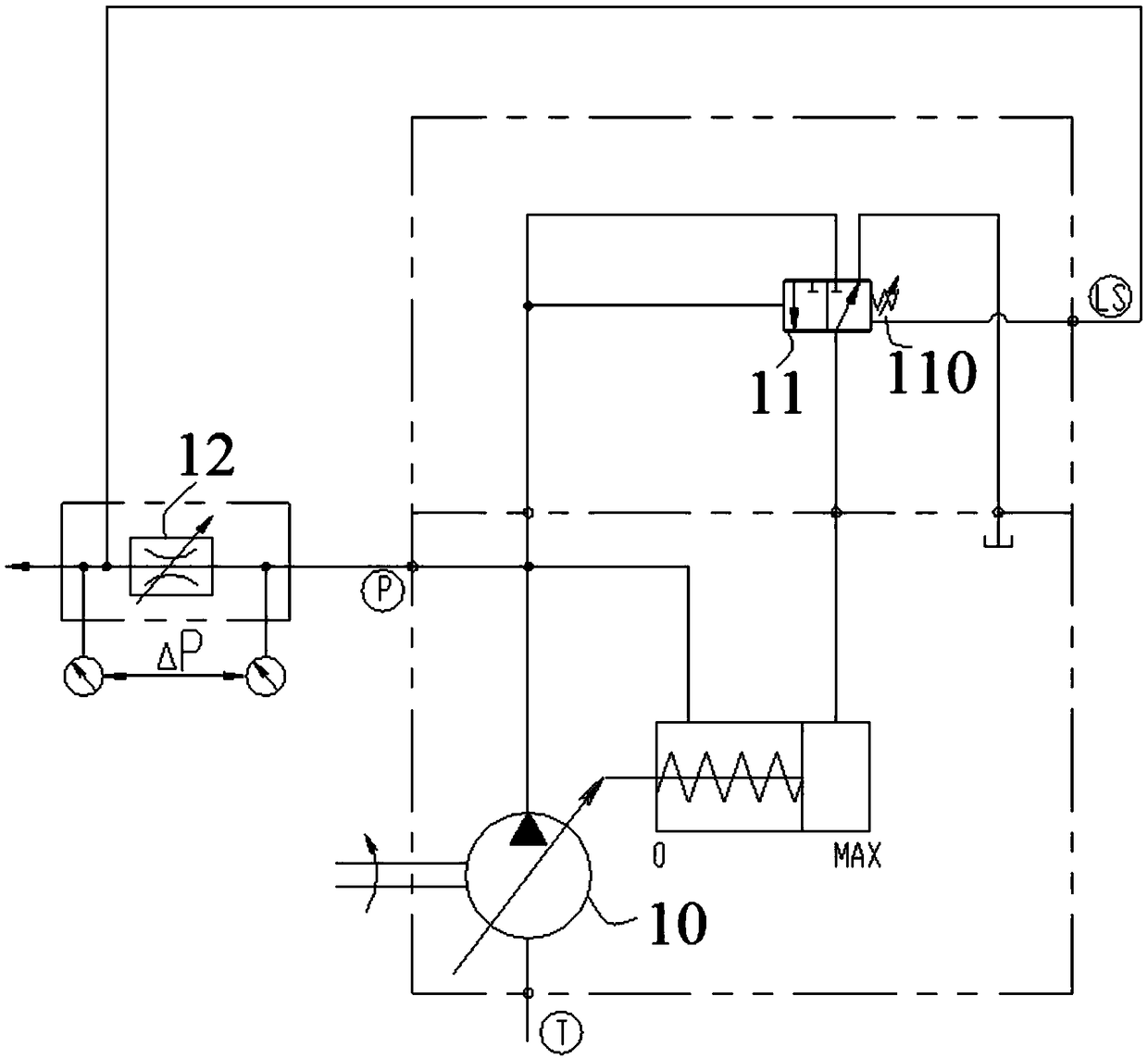

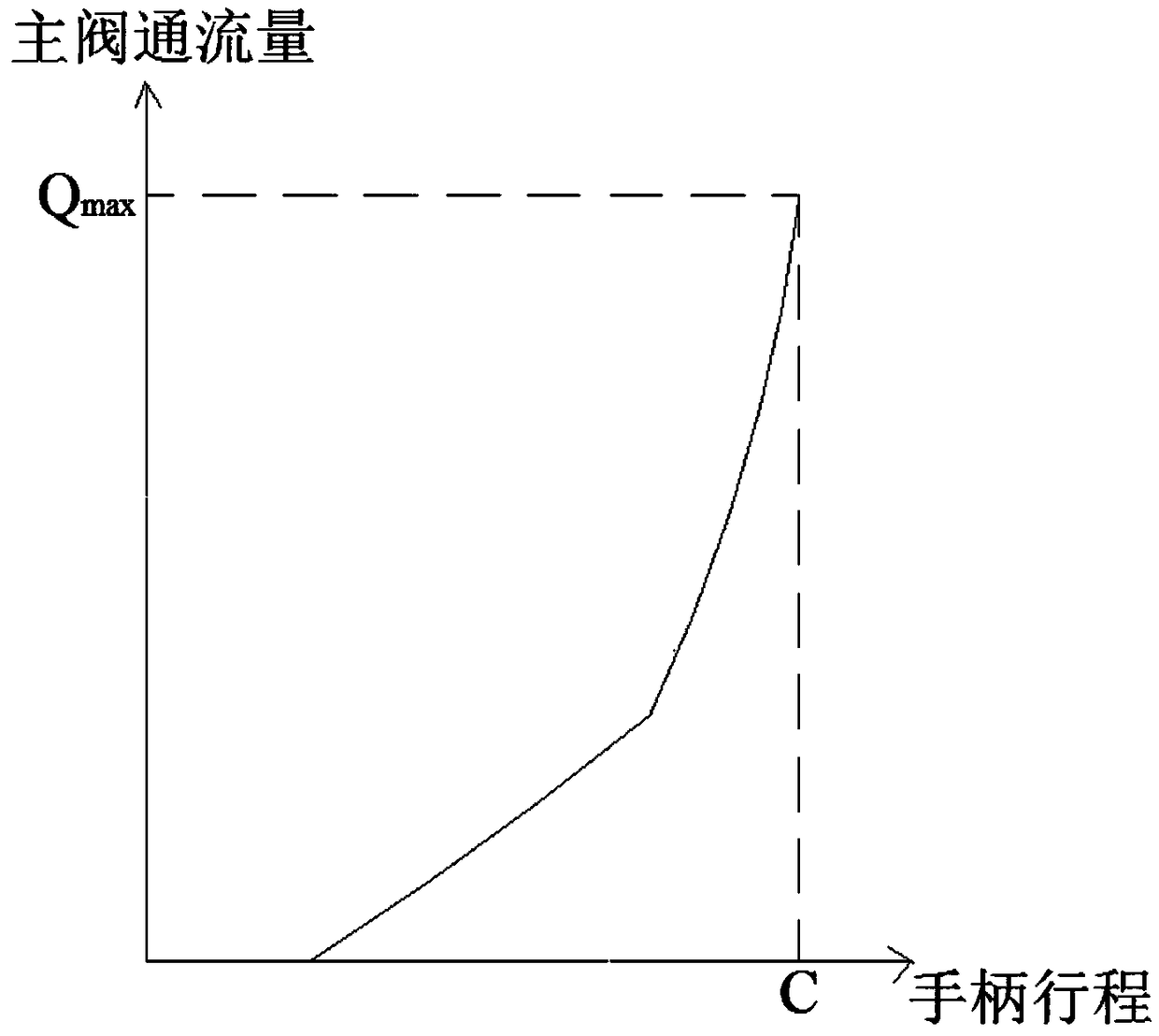

[0042] figure 1 It is a structural diagram of a hydraulic system in the prior art. The hydraulic system mainly includes: a hydraulic pump 10, a variable valve 11, a main valve 12 and the like. Wherein, the left end of the variable variable valve 11 is connected with the outlet of the hydraulic pump 10 (the pressure here is P), and its right end is connected with the spool spring 110 (the preset spring force is F 弹 ) and the load feedback oil port LS of the main valve 12 (the pressure here, that is, the load pressure is P LS ) connected. The working principle of the hydraulic pump 10 is as follows: the output flow Q of the hydraulic pump 10 is introduced into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com