Anti-toppling placement device

An anti-dumping and placing seat technology, applied in the direction of connecting components, suction cups, furniture parts, etc., can solve the problems of falling and damaged objects, dumping, and no anti-dumping device, so as to avoid the increase of the tilting trend and prevent the dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

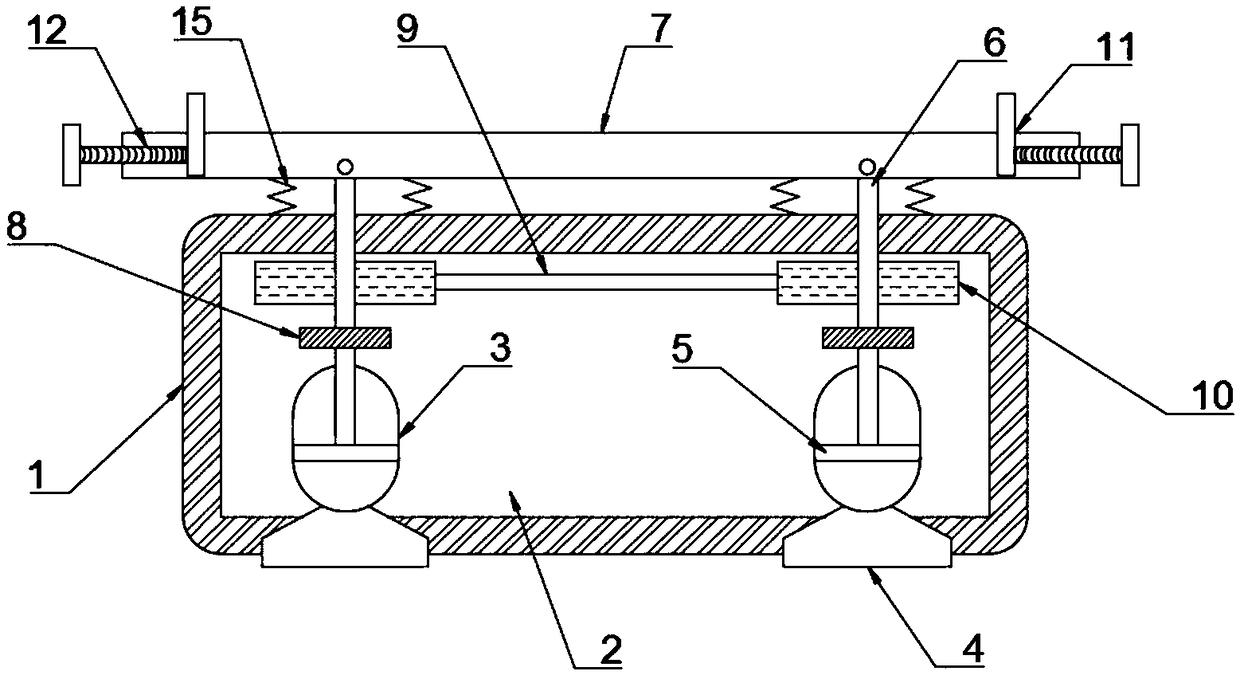

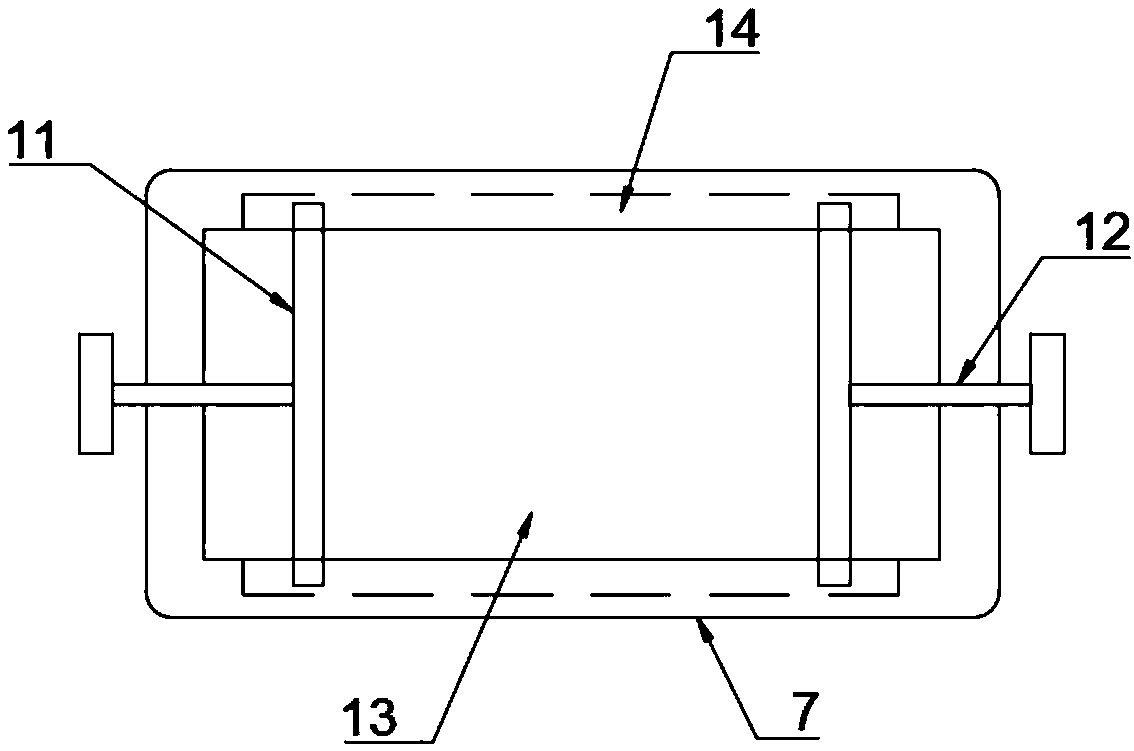

[0024] refer to Figure 1-2 , an anti-dumping placement device, including a placement seat 1, a cavity 2 is opened inside the placement seat 1, and two airbags 3 are fixed on the inner bottom of the cavity 2, and each airbag 3 is made of hard plastic material , to avoid the change of the volume of the airbag 3 due to the change of the gas, the inner wall of each airbag 3 is slidably connected with a piston 5, and the upper side wall of each piston 5 is fixedly connected with a moving rod 6, and the two moving rods 6 The upper end runs through the upper side wall of the airbag 3 and the inner top wall of the cavity 2 to the upper side wall of the placement seat 1, and the lower side wall of each air bag 3 is fixed with a suction cup 4, which is convenient for the suction cup 4 and the placement seat. 1 The suction between the placement surfaces, and then complete the suction and fixation of the placement seat 1, each suction cup 4 is connected with the inside of the air bag 3, ...

Embodiment 2

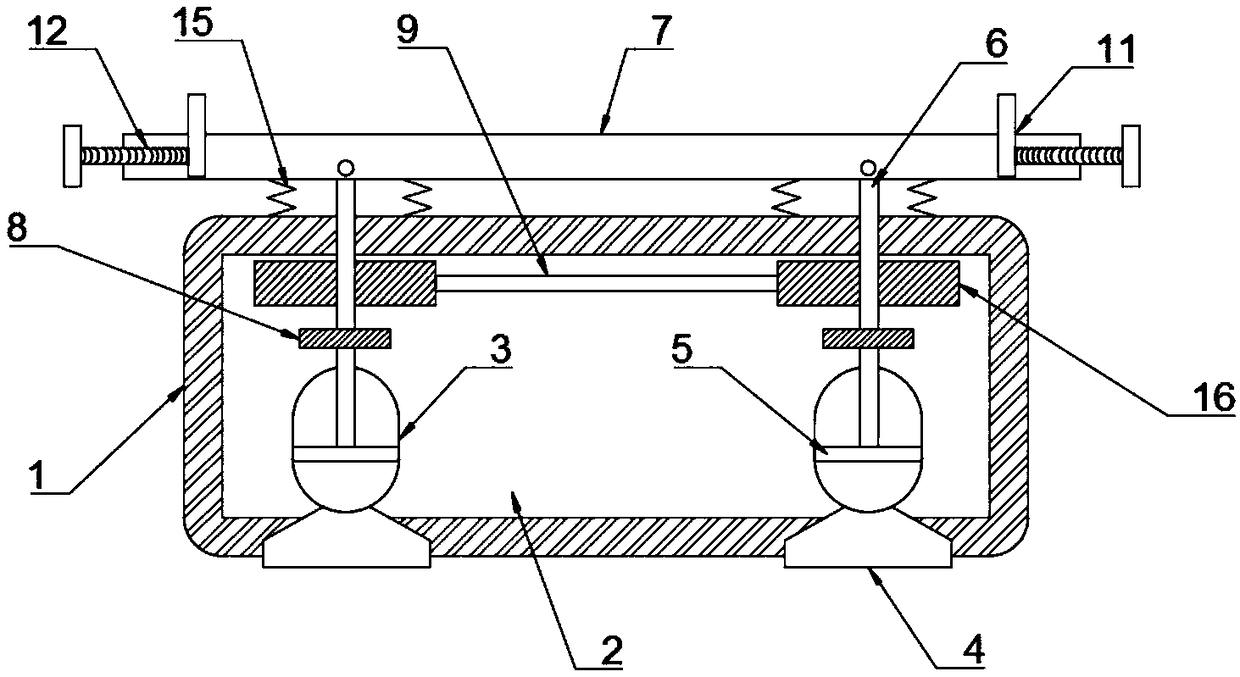

[0032] refer to image 3 , the anti-movement mechanism includes a fixed plate 9 fixedly connected to the inner wall of the cavity 2, and second magnets 16 are fixedly connected to both sides of the fixed plate 9, and each second magnet 16 is provided with a slide, each slide Matching the size and position of one of the moving rods 6, the upper end of each moving rod 6 passes through the sliding opening and is slidably connected with the inner wall of the sliding opening, and the outer wall of each moving rod 6 is sleeved with a first magnet 8, Each first magnet 8 is all positioned at the lower side of the second magnet 16, and the magnetic properties of the first magnet 8 and the second magnet 16 are opposite. When the other side of 7 pulls the moving rod 6 to move upwards, the first magnet 8 moves to one side of the second magnet 16, and the repulsive force of the second magnet 16 to the first magnet 8 prevents the moving rod 6 from moving upwards, avoiding An increase in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com