Cylinder liner outer diameter and roundness comprehensive measuring device and using method

A comprehensive measurement and cylinder liner technology, applied in measuring devices, mechanical measuring devices, mechanical diameter measurement, etc., can solve the problems of complex internal structure, troublesome operation, difficult repair, etc., and achieve simple structure, low cost and high measurement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention will be further described.

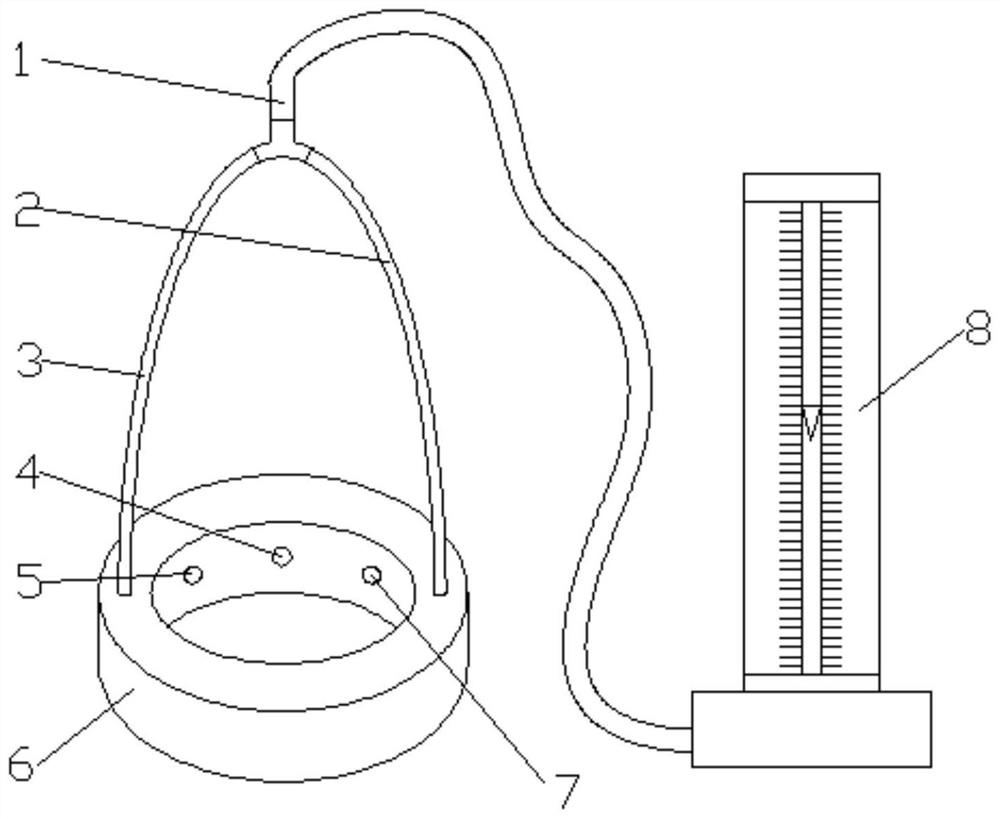

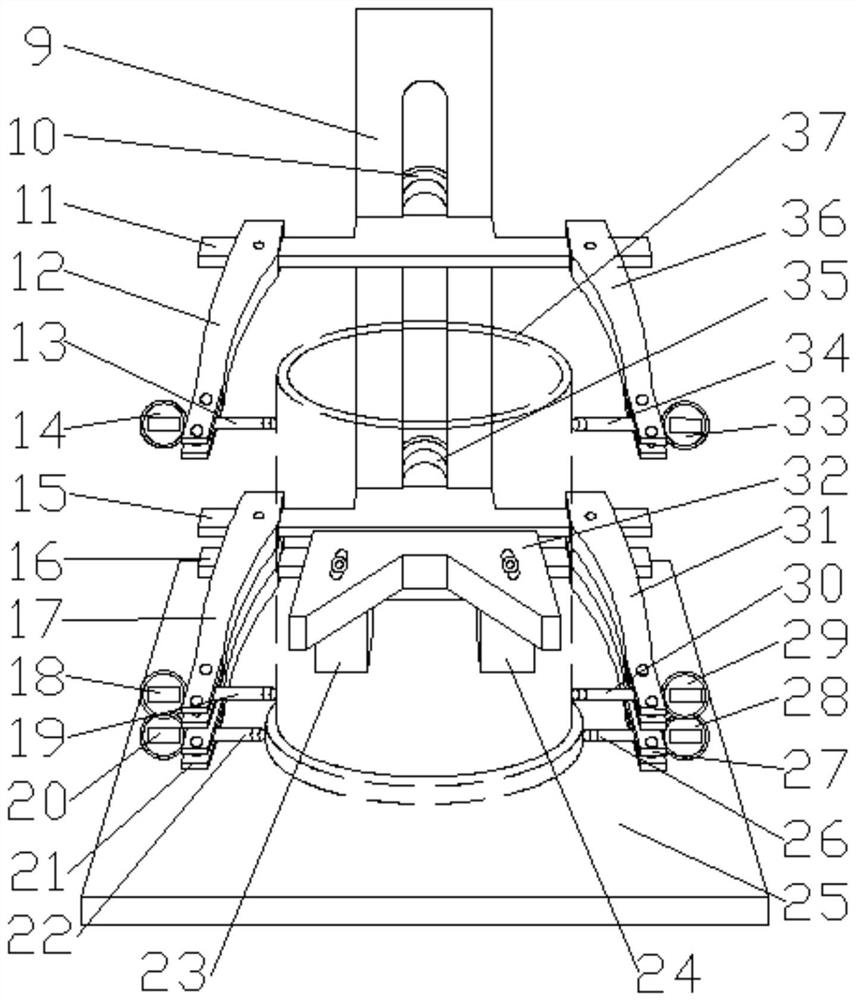

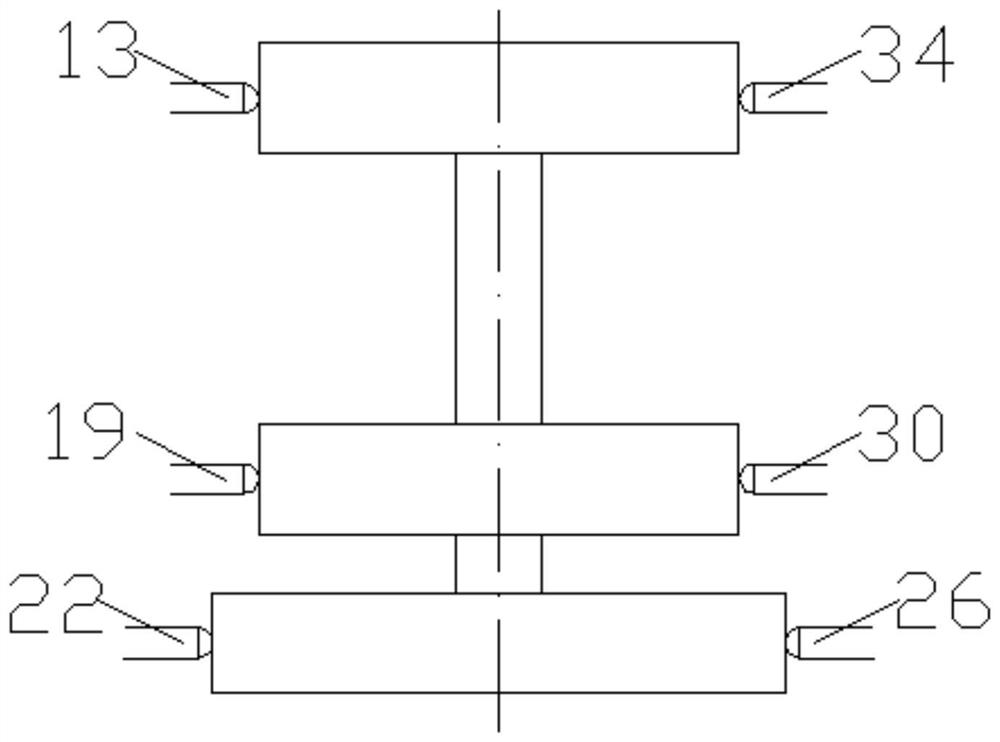

[0031] Such as figure 2As shown, the cylinder liner outer diameter and roundness comprehensive measuring device of the present invention are respectively fixed on the six electronic alarm displays 14, 18, 20, 28, 29, 32 of No. 1 to No. On the head arms 12, 17, 21, 27, 31, 36, make the six contacts 13, 19, 22, 26, 30, 34 from No. 1 to No. 6 face inward and directly contact with six different key positions on the outer wall of the cylinder liner The dimension deviation of the outer wall of the cylinder liner is measured. In addition, the roundness of the cylinder liner at different positions can be measured by rotating the cylinder liner around its symmetry axis at a certain angle for multiple measurements.

[0032] Such as Figure 4 As shown, it is a schematic diagram of the fixed adjustment structure of the electronic display alarm on the contact arm. The end of the contact arm 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com