An Erosion On-Site Test Device for Equal Flow Type Multi-stage Velocity Mixed Transport Pipeline Erosion

An on-site test and constant flow rate technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as poor safety and reliability of continuous operation, high construction cost of test devices, and heavy operation and maintenance workload, etc., to achieve Simple structure, low investment, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

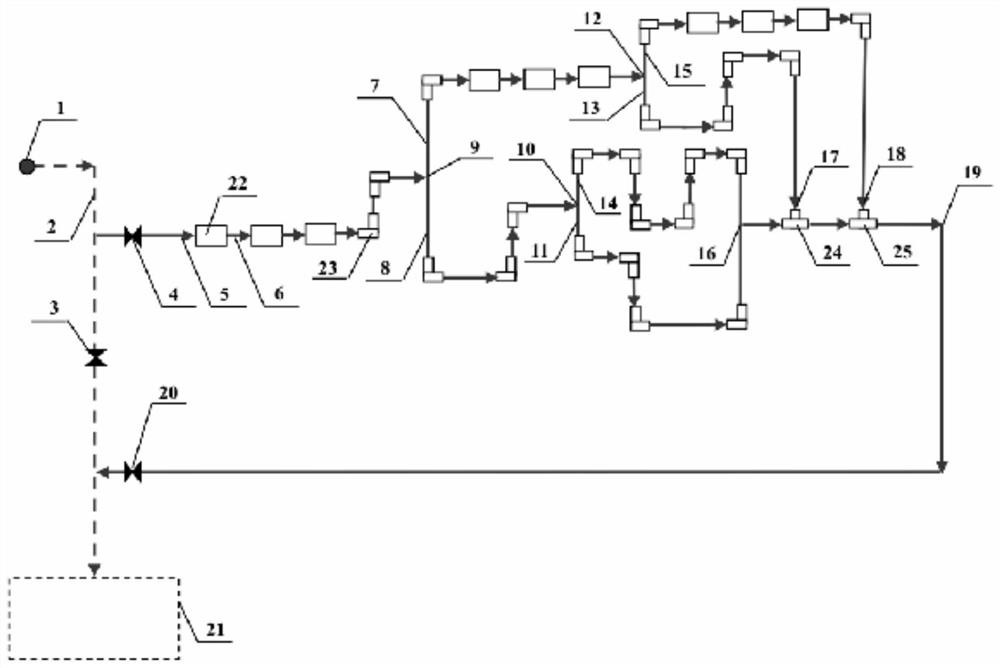

[0065] Applying the present invention to a condensate gas field in Tarim, a set of on-site test device for scour corrosion of oil-gas mixed transportation pipeline with 3-level flow velocity was built and put into operation. 4 m 3 / d, gas-liquid ratio 10000m 3 / m 3 .

[0066] 1. Overview of the test device

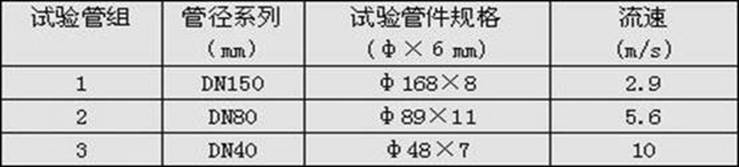

[0067] The investment in the construction of the erosion corrosion test device was reduced from 2.14 million yuan using the conventional technical solution to 1.25 million yuan using the technical solution of the present invention, saving 41.6% of the project investment; it reached the level 3 test flow rate: 2.9m / s, 5.6m / s , 10m / s, got the erosion corrosion test speed difference of 2.7 m / s, 4.4 m / s, 7.1 m / s; carried out the bare steel pipe, titanium nano-ceramic coating pipe, titanium nano-polymer coating pipe, epoxy The erosion corrosion test of 6 kinds of straight pipe test fittings such as powder-coated pipes, 1D~6D elbow test pieces, and different diameter tee tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com