LED light bar illumination test mechanism

A technology of LED light strips and testing institutions, applied in the direction of lamp testing, etc., can solve the problems of low detection accuracy, limit detection efficiency, increase time cost, etc., and achieve the effect of increasing detection accuracy, improving detection accuracy, and saving time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

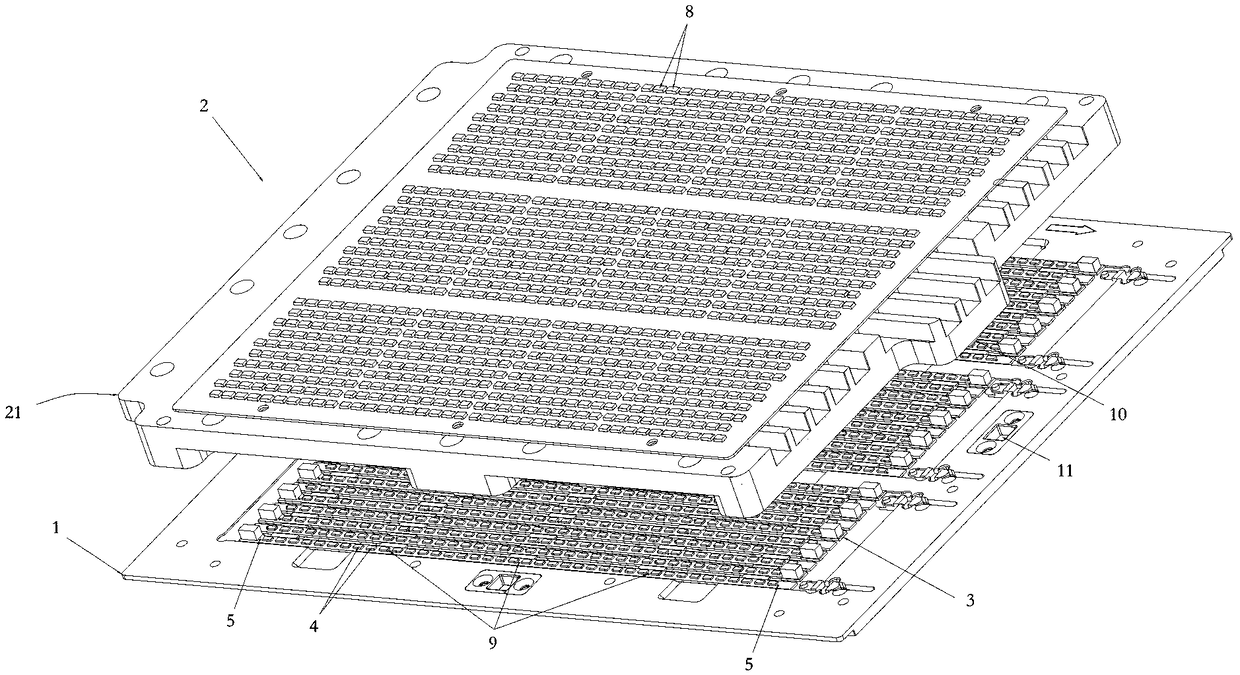

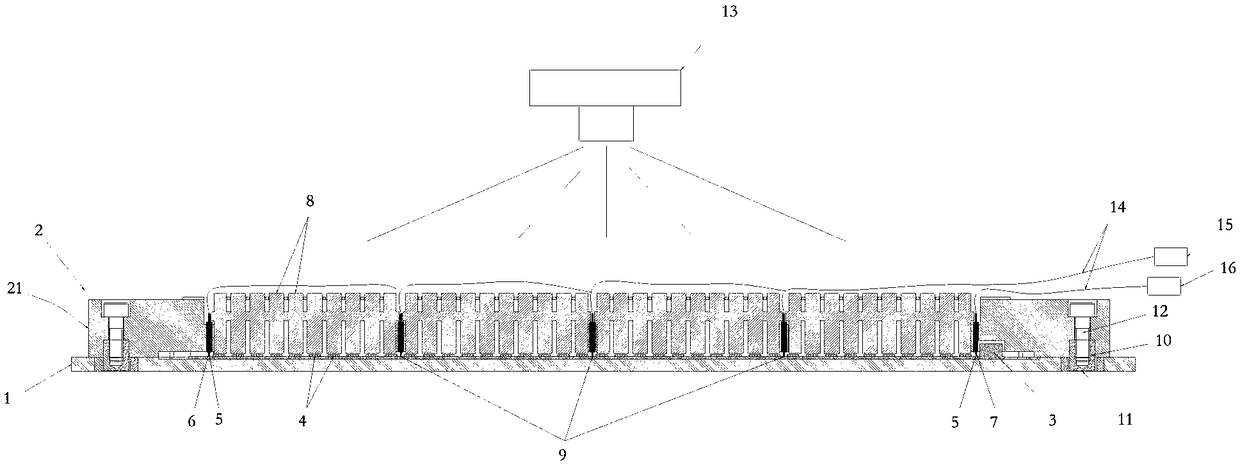

[0022] Shown in conjunction with the accompanying drawings is a specific implementation of the LED light bar lighting test mechanism of the present invention. First, it includes a lower mold 1 and a circuit board 3 arranged on the lower mold 1. The circuit boards 3 are arranged in parallel Thirty groups of test units are arranged, and each group of test units includes forty LED light-emitting lamps 4 distributed laterally at intervals, and the distance between two adjacent LED light-emitting lamps 4 in the test units is equal.

[0023] The circuit board 3 is provided with two main contacts 5 and three auxiliary contacts 9 corresponding to each group of test units, as shown in the figure, corresponding to any group of test units, two main contacts 5 are respectively set On the outside of the corresponding LED lights 4 on both sides, an auxiliary contact 9 is provided between two adjacent LED lights 4 every ten LED lights 4 .

[0024] Secondly, the testing mechanism also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com