A structural design method of automobile sheet metal parts based on finite elements

A technology for automotive sheet metal parts and structural design, applied in the field of automotive sheet metal structural design, can solve problems such as blind design direction, and achieve the effect of light structure weight and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

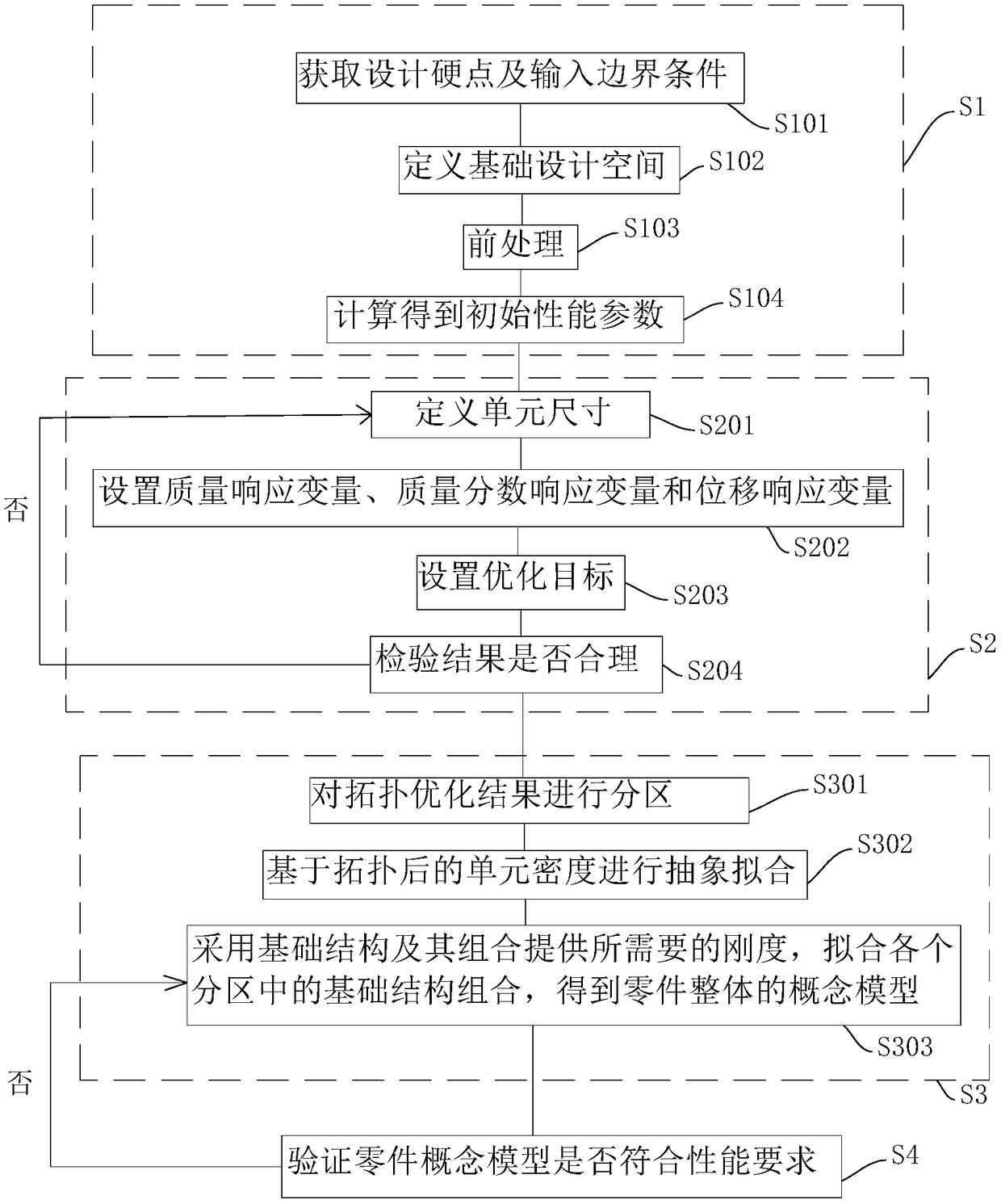

[0051] see figure 1 . The invention provides a method for designing a structure of an automobile sheet metal part based on finite elements, and the method for designing includes the following steps:

[0052] S1. Define the design space and boundary conditions;

[0053] S2. The force transmission path is obtained by topology optimization;

[0054] S3. Design a conceptual model of a part according to the topology result;

[0055] S4. Verify whether the conceptual model of the part meets the performance requirements.

[0056] Step S1 comprises the following steps:

[0057] S101. Obtain design hard points and boundary conditions;

[0058] S102. defining a basic design space;

[0059] S103. Pretreatment;

[0060] S104. Calculate and obtain initial performance parameters.

[0061] In step S101, relevant input conditions given by the design department are collected, including design hard points, boundary conditions, etc. In step S102, according to the position of the surroun...

Embodiment 2

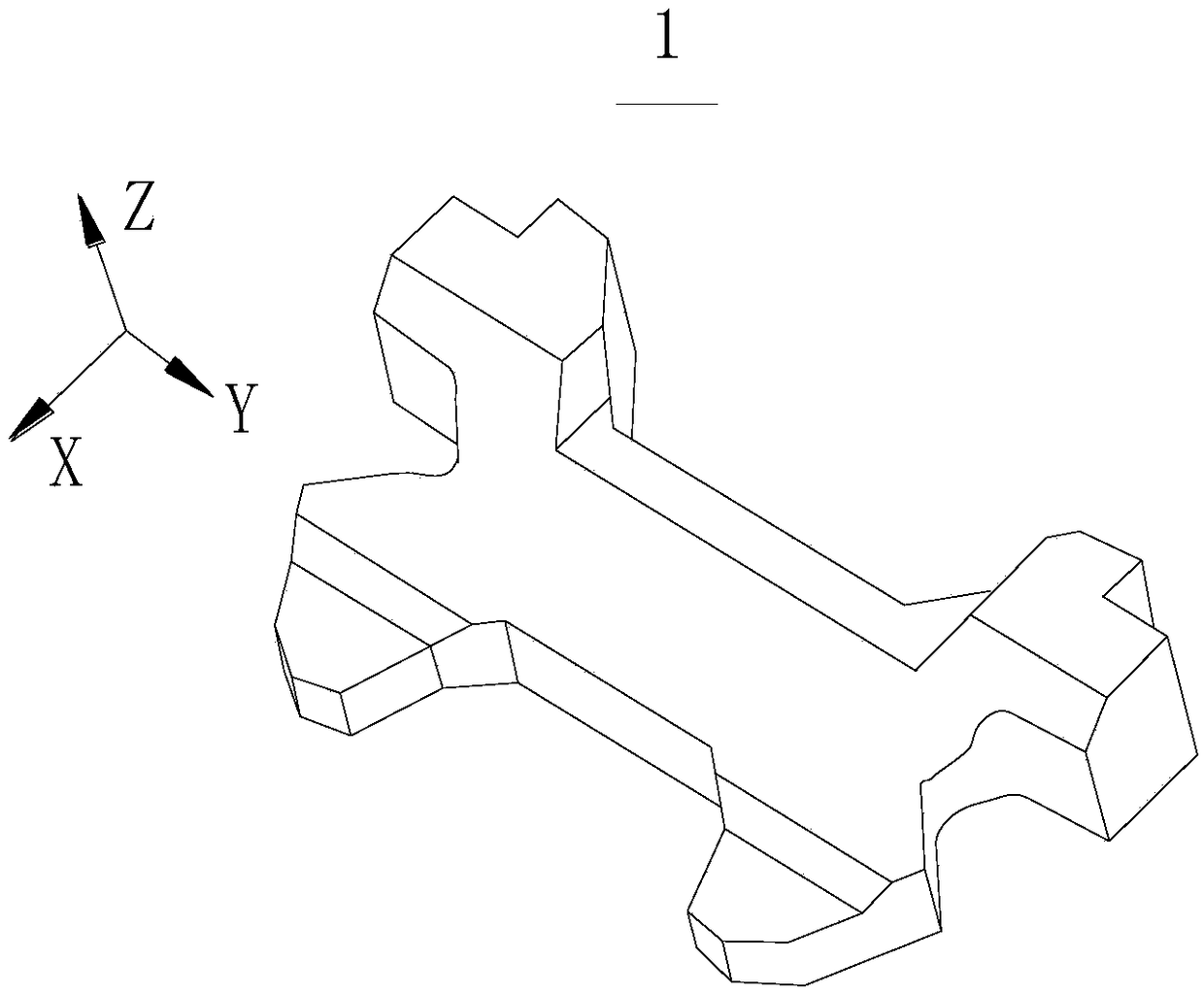

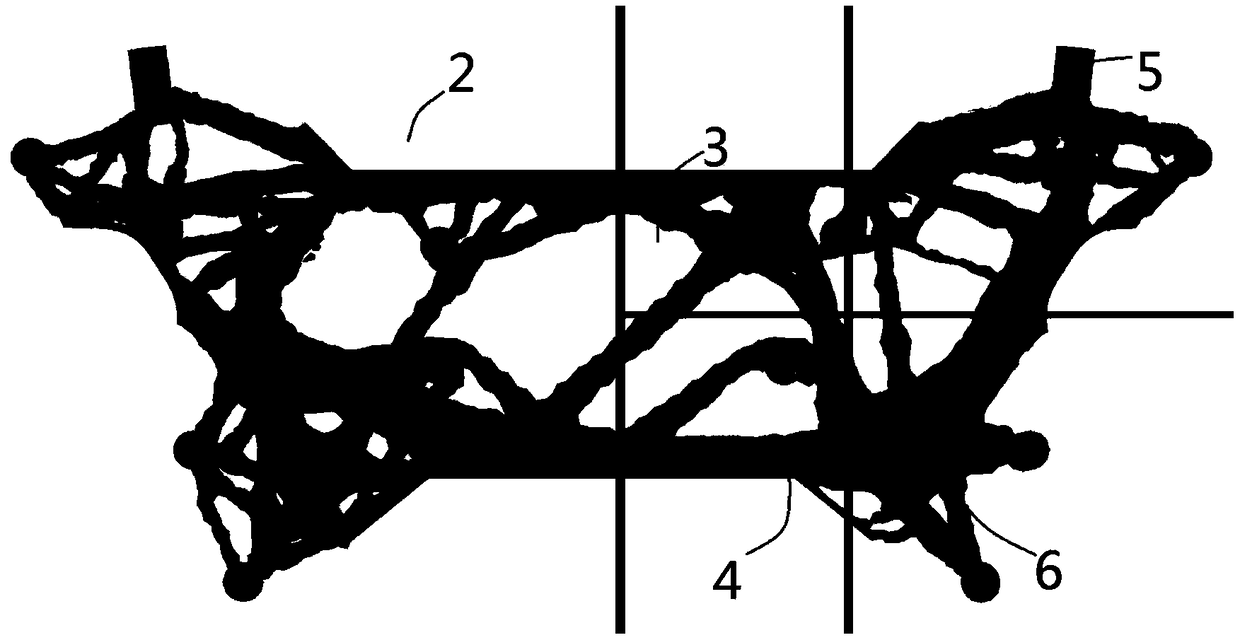

[0083] see Figure 2-Figure 5 . This embodiment provides an application of a finite element-based automobile sheet metal structure design method in the design of the automobile front sub-frame. The front subframe of the car is a sheet metal part.

[0084] According to embodiment 1, carry out the structural design of automobile front auxiliary frame according to the following steps:

[0085] S1. Define the design space and boundary conditions of the front subframe of the automobile;

[0086] S2. The transmission path of the force in the front subframe of the automobile is obtained by topology optimization;

[0087] S3. Design the conceptual model of the front subframe of the car according to the topology results.

[0088] S4. Verify whether the conceptual model of the car's front subframe meets the performance requirements.

[0089] In step S1, the following steps are included:

[0090] S101. Obtain the design hard points and boundary conditions of the front sub-frame of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com