Double-break-point medium voltage magnetic retention relay

A magnetic latching relay, double breakpoint technology, applied in electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of inability to meet the stress requirements of equipment systems, high precision requirements, and inability to break, to improve switching capabilities and Debugibility, increase the diversion area, avoid the effect of easy decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

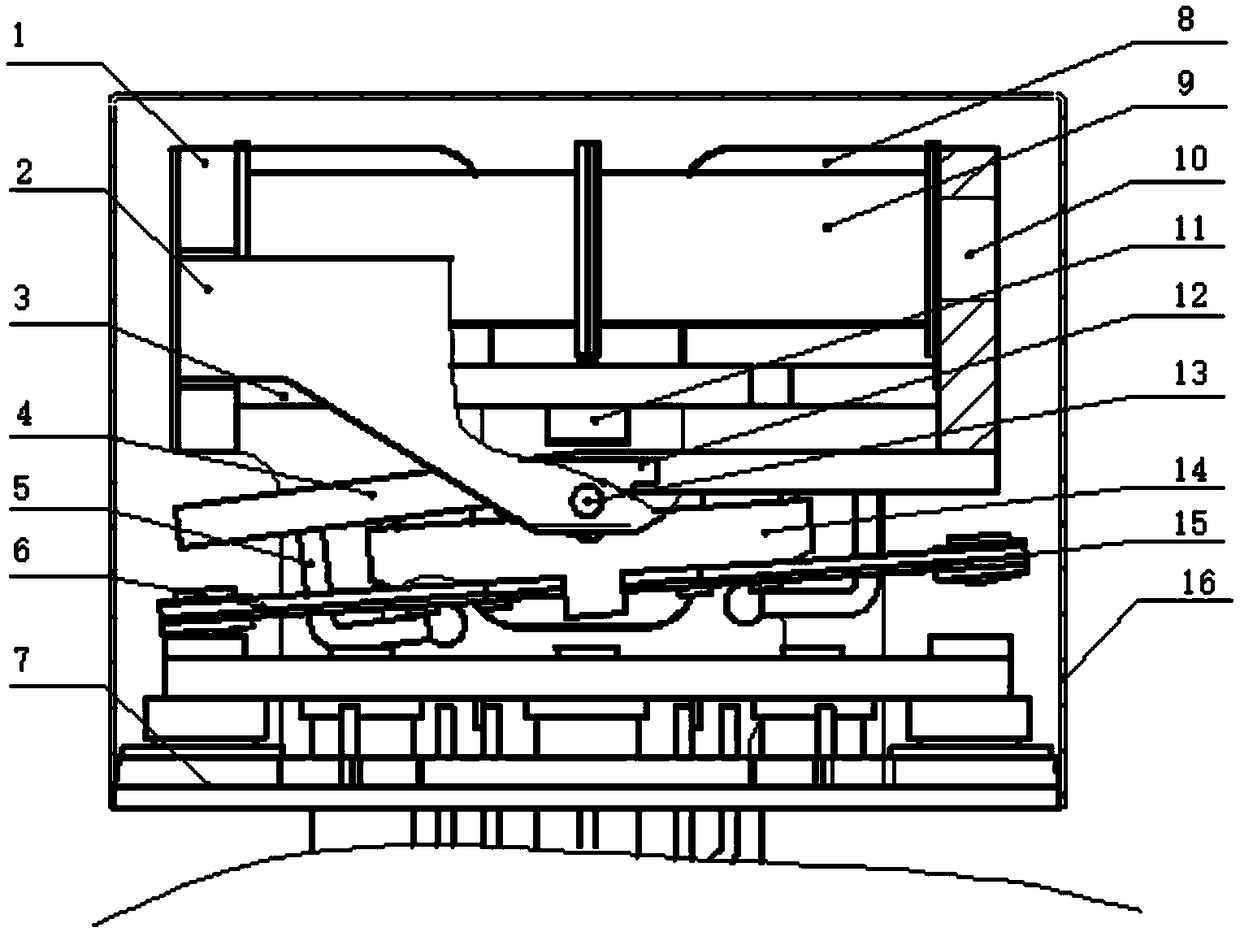

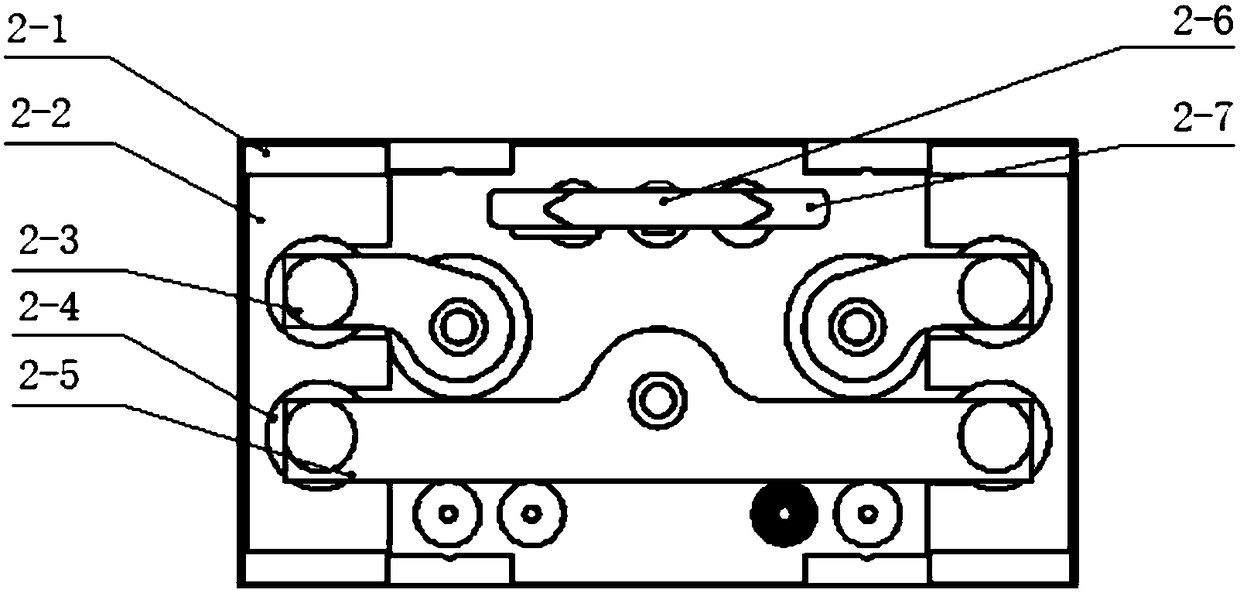

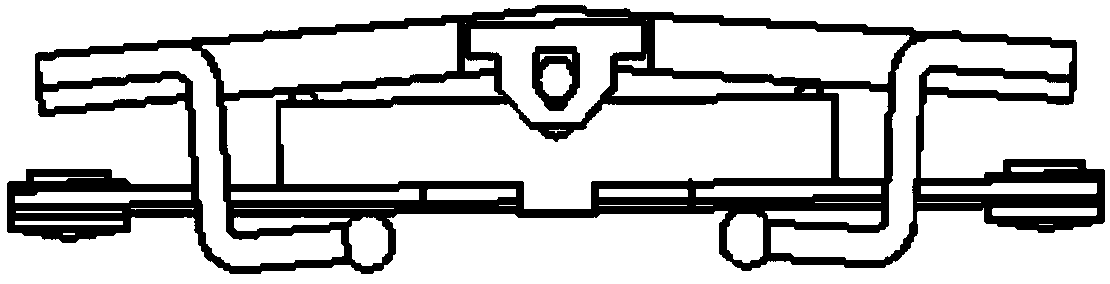

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a double breakpoint medium-voltage magnetic latching relay includes a case 16, and a coil combination, an armature combination and a contact system 7 are arranged in the case 16. The coil combination is located above the armature combination, and the contact system 7 is located below the armature combination. . In addition, the coil assembly can be fixedly connected to the armature assembly through the shaft support piece 2 and the shaft 13 .

[0025] In this embodiment, the coil combination includes a yoke 1, a magnetic steel 3, a coil 9, an iron core 10, and a magnetizer 11. After passing through the coil 9, the iron core 10 is installed on the yoke 1 through a magnet 3, and the magnetizer 11 is installed on the magnet. On the lower end surface of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com