A high-voltage current-limiting fuse having a signaling device

A fuse and high-voltage technology, applied in emergency protection devices, electrical components, circuits, etc., can solve problems such as out-of-control, damage, and inaccurate measurement of controlled electrical appliances, and achieve stable layout, reasonable structure, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

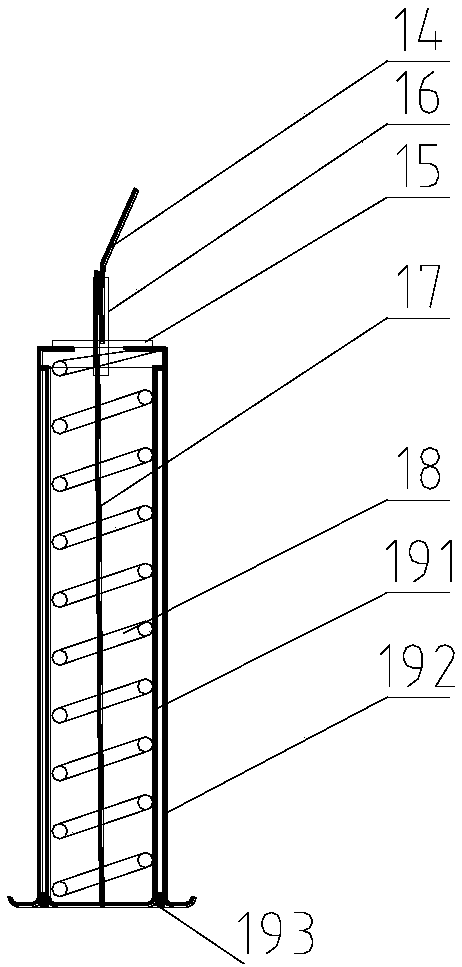

[0048] Embodiment 1, the housing 221 is provided with a pair of weak structures 2211, the first electrode 224 and the second electrode 225 are accommodated in the pair of weak structures 2211 respectively, and the container 222 is made of non-conductive non-metallic material. In this way, the first electrode and the second electrode are simultaneously subjected to external force, pierce the weak structure, and contact the electrolyte to realize energy supply; the container is made of non-conductive non-metallic material, which is corrosion-resistant and improves the storage time of the battery structure.

[0049] The bottom ends of the first electrode 224 and the second electrode 225 are both tapered. In this way, the first electrode and the second electrode can break through the weak structure more easily, ensuring reliable energy supply.

Embodiment 2

[0050] Embodiment 2, the housing 221 is provided with a weak structure 22 and a housing hole 2212, the electrode 1 224 is accommodated in the weak structure 2211, and the electrode 2 225 is accommodated in the housing hole 2212 In, and connected with the container 222, the container 222 is made of conductive non-metallic material. In this embodiment, the container is made of a conductive non-metallic material. After being connected to the second electrode, the second electrode and the container form an electrode as a whole. In this way, the second electrode is fixed, and it is only necessary to push the first electrode into the container to contact the electrolyte. A battery structure can be formed, which makes the entire battery structure more streamlined and improves the reliability of the battery structure.

[0051] The bottom end of the first electrode 4 is conical. In this way, the electrode one can break through the weak structure more easily, ensuring reliable energy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com