A vertical motor assembly apparatus and a motor assembly method

A technology for assembling equipment and vertical motors, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of unfavorable large-scale promotion, low installation accuracy, and high work intensity, and achieves low price and installation accuracy. High and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

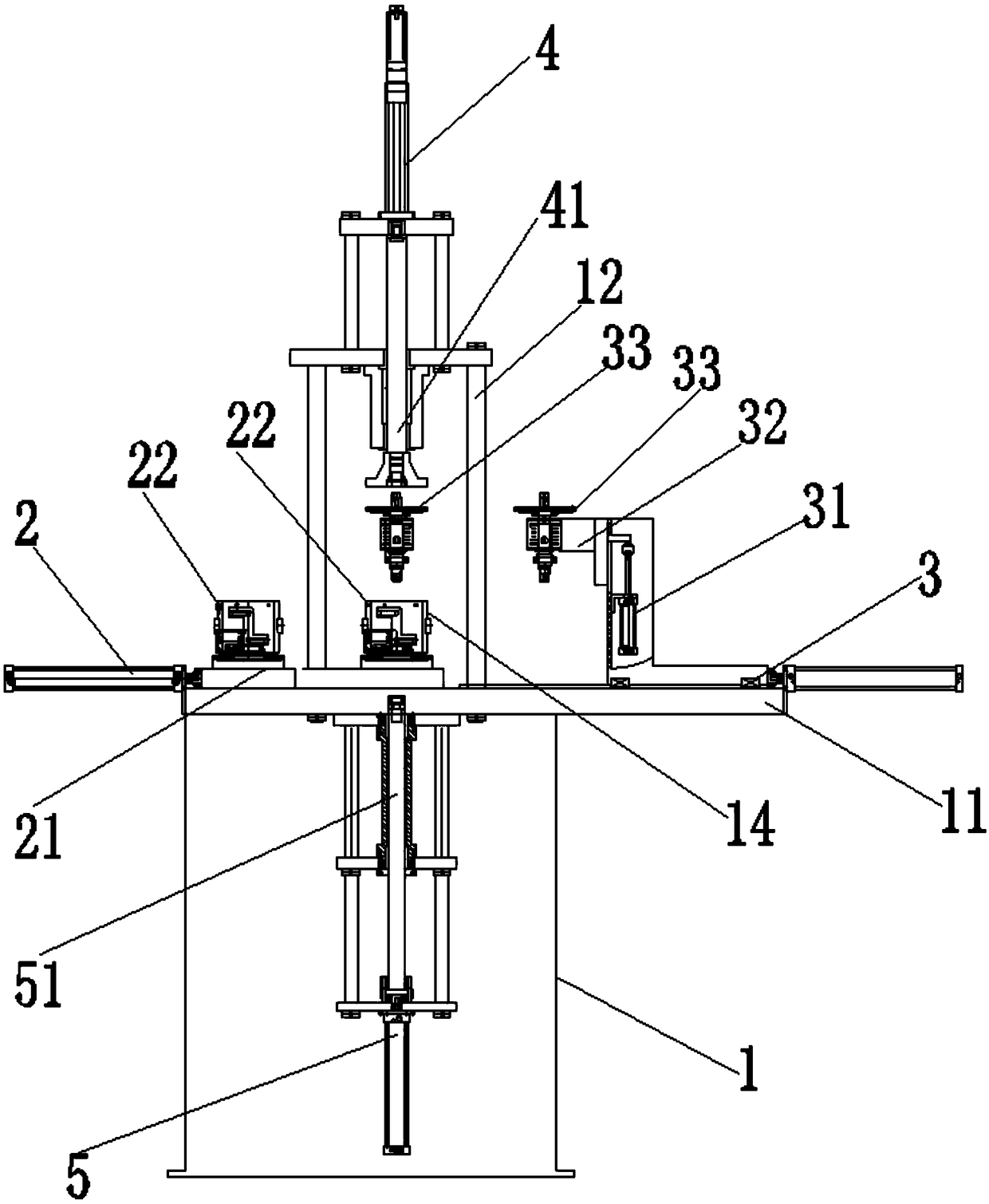

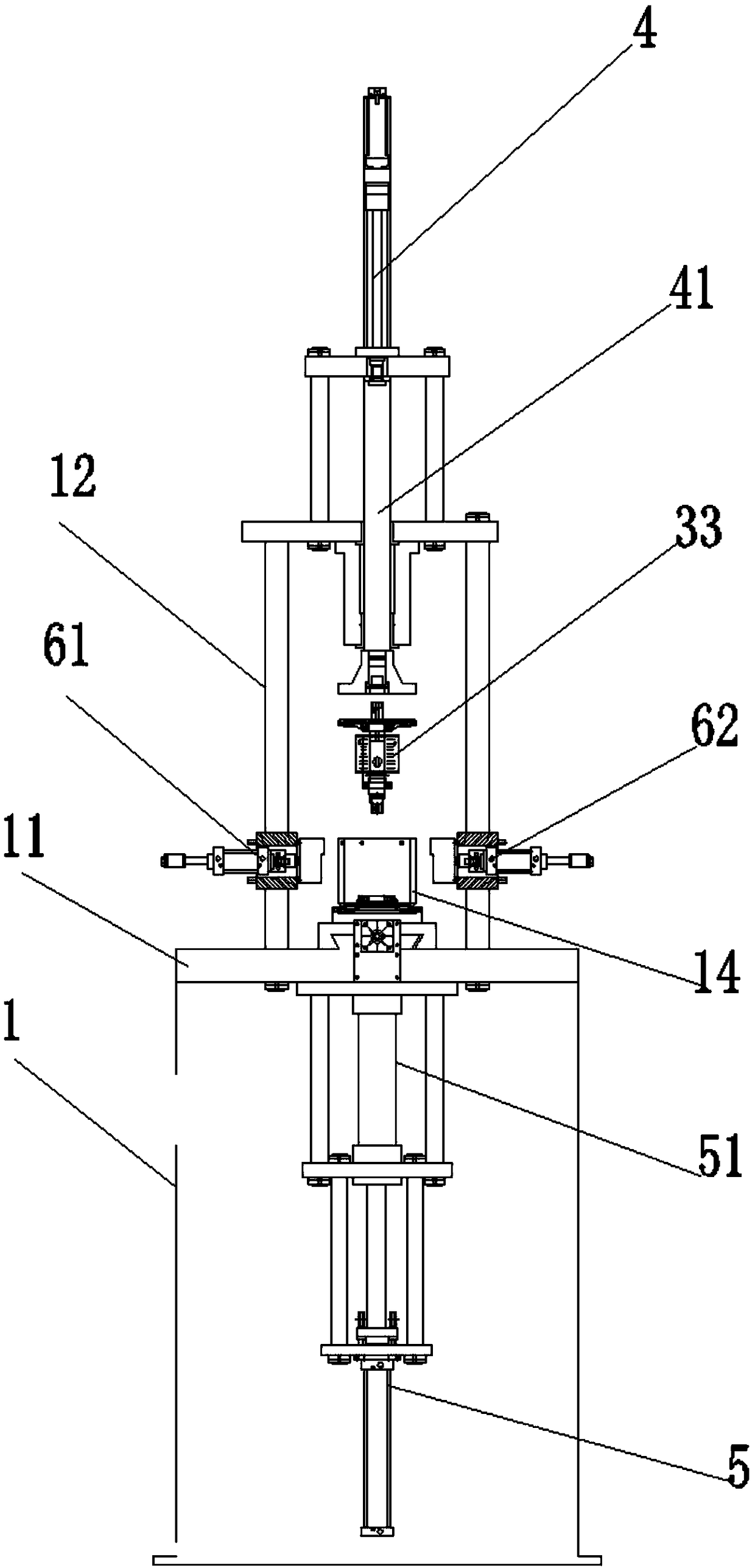

[0033] Example 1, see figure 1 and figure 2 , a preferred embodiment of the invention, a vertical motor assembly equipment, including a frame 1, a work platform 11 is set on the frame, and a positioning center 14 is set on the work platform. The improvement is that it also includes:

[0034] The upper mandrel pushing mechanism and the lower mandrel pushing mechanism are arranged oppositely up and down, the upper mandrel pushing mechanism 4 and the lower mandrel pushing mechanism 5 are respectively used to push the upper mandrel 41 downward and the lower mandrel 51 upward;

[0035] The positioning center 14 is located between the upper spindle pushing mechanism and the lower spindle pushing mechanism, and the positioning center 14 coincides with the center line of the upper spindle pushing mechanism and the lower spindle pushing mechanism;

[0036] The stator assembly pushing mechanism and the rotor assembly pushing mechanism respectively arranged on the front and rear sides ...

Embodiment approach

[0041] As an embodiment of the present invention, both the stator assembly pushing mechanism and the rotor assembly pushing mechanism include a station seat 21 and a driving power assembly connected with the station seat, and the pushing power assembly is used to push the stator assembly or rotor on the station seat The assembly is pushed horizontally toward the positioning center 14, and a longitudinal movement mechanism 31 for driving the rotor assembly in the station seat to move up and down is provided between the station seat of the rotor assembly pushing mechanism and the driving power assembly of the rotor assembly pushing mechanism. The driving power assembly includes a linear cylinder arranged horizontally and a second electromagnetic valve connected with the linear cylinder arranged horizontally, and the second electromagnetic valve is connected with a controller. The longitudinal movement mechanism 31 includes a linear motor and a solenoid valve, which is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com