A multi-stage electric heating tube and a manufacturing method thereof

An electric heating tube and heating wire technology, applied in ohmic resistance heating parts, heating element materials, heating element shapes, etc., can solve the problems of inability to adjust, low temperature control accuracy, accelerated product aging, etc., to improve safety and Reliability, improve temperature control accuracy, improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

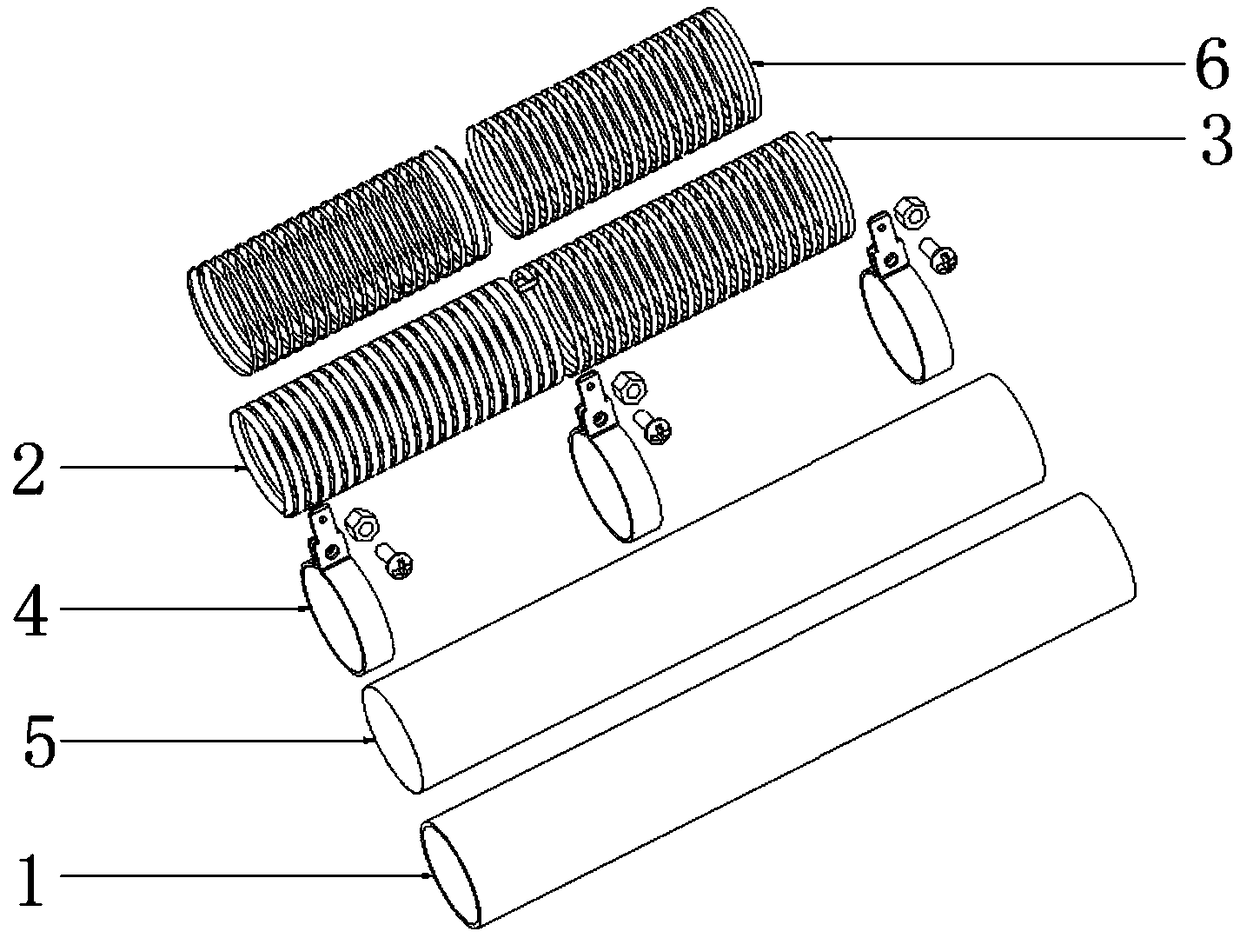

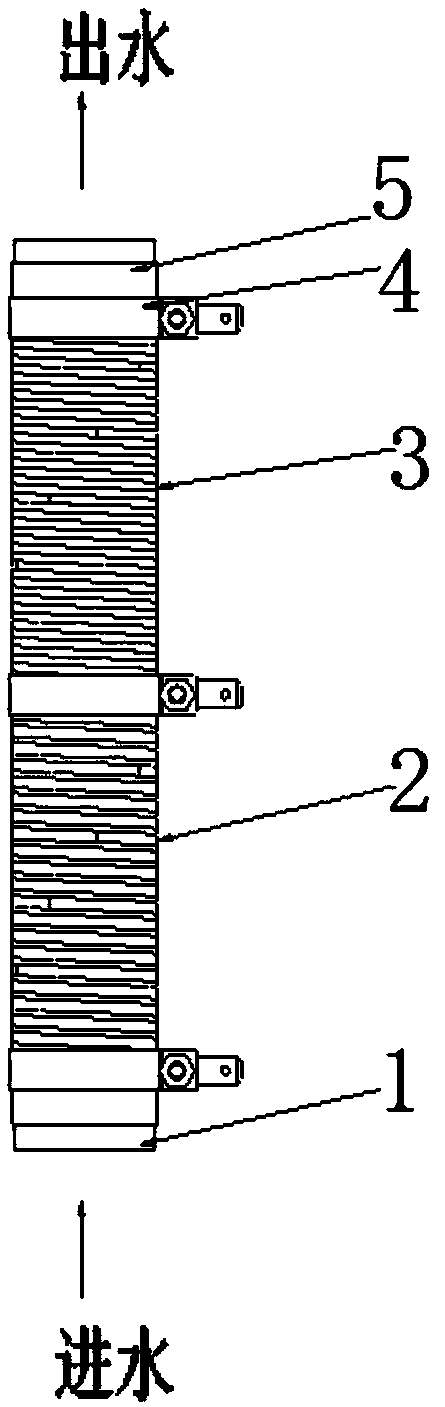

[0034] Such as figure 1 with figure 2 As shown, a multi-stage electric heating tube is used for heating liquid in drinking water equipment. The multi-stage electric heating tube includes a diversion tube 1 and a heating layer wrapped outside the diversion tube 1. The diversion tube 1 is made of stainless steel. The flow direction of the liquid in the draft tube 1 is downward inflow and upward exit, and the heating layer is energized and heated to increase the temperature of the liquid in the draft tube 1 . A first insulating layer 5 is arranged between the flow guide tube 1 and the heating layer, and the first insulating layer 5 is made of an insulating film to isolate the flow guide tube 1 from the heating layer to prevent leakage.

[0035] In this embodiment, the heating layer is composed of two sections of heating elements. The two sections of heating elements are respectively made of the first heating wire 2 and the second heating wire 3. The first heating wire 2 and the...

Embodiment 2

[0037] In this embodiment, on the basis of the above embodiments, the first heating wire 2 and the second heating wire 3 are made of the same material, and the thickness, width and length of the two are different, and different power sections can be configured according to different requirements. , to expand the heating range of the heating tube, suitable for heating requirements of different environments and different liquids.

Embodiment 3

[0039] This embodiment is different from the above embodiments in that the materials of the first heating wire 2 and the second heating wire 3 are also different, which can further expand the heating range of the heating tube and improve the heating accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com