Stirring reaction device for producing carboxymethyl cellulose nitrate

A technology of carboxymethyl cellulose and stirring reaction, applied in mixers with rotating stirring devices, chemical/physical/physicochemical fixed reactors, transportation and packaging, etc., can solve adverse reactions, uneven stirring, etc. problem, to achieve the effect of sufficient stirring, uniform stirring, and favorable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

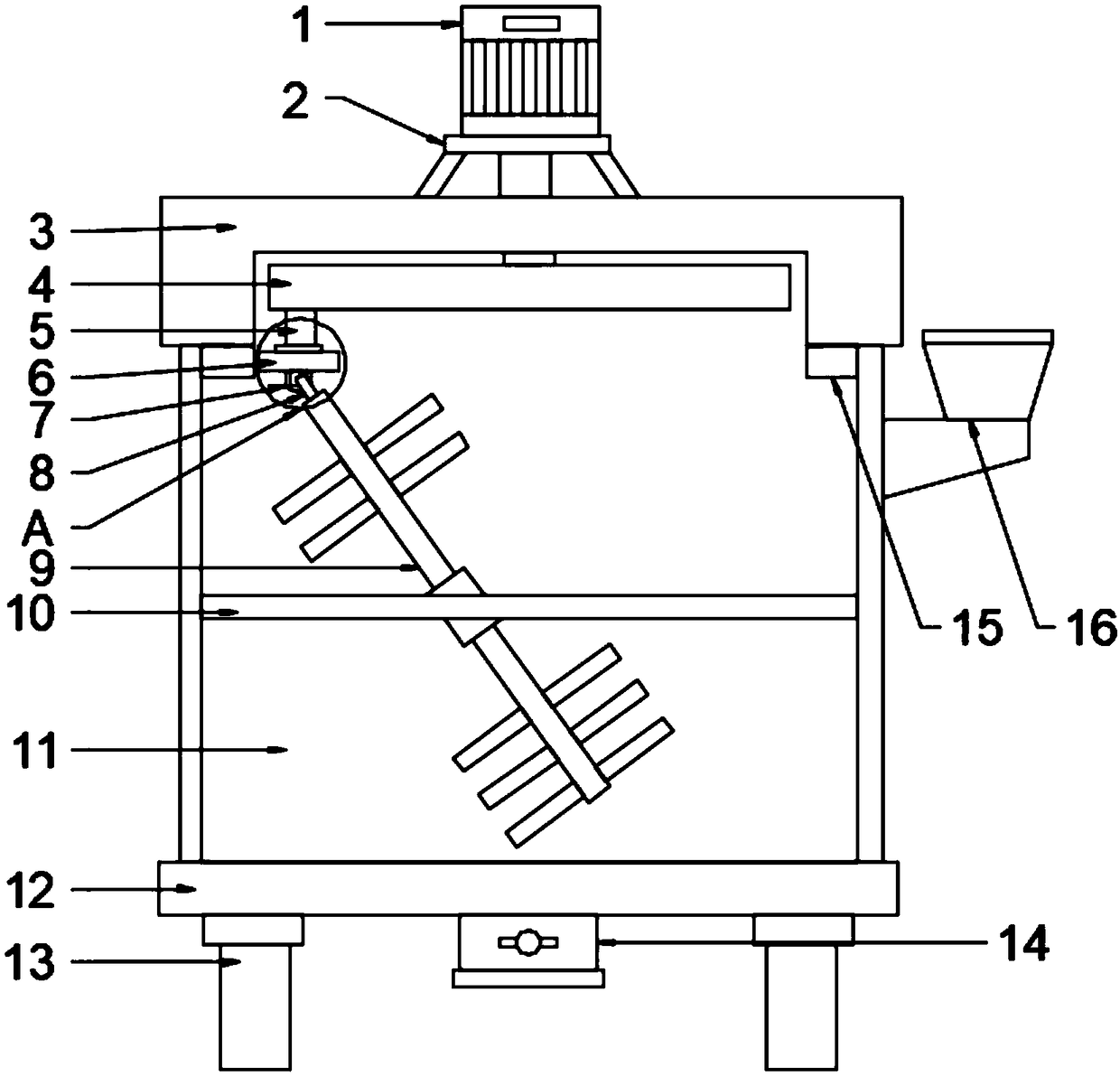

[0025] See Figure 1-4 , A stirring reaction device for the production of carboxymethyl cellulose nitrate, comprising a tank body 11, the tank body 11 is installed with a shaking and rotating frame 9, the shaking and rotating frame 9 can realize the rotation and shaking during the working process, and the stirring is uniform. Conducive to reaction.

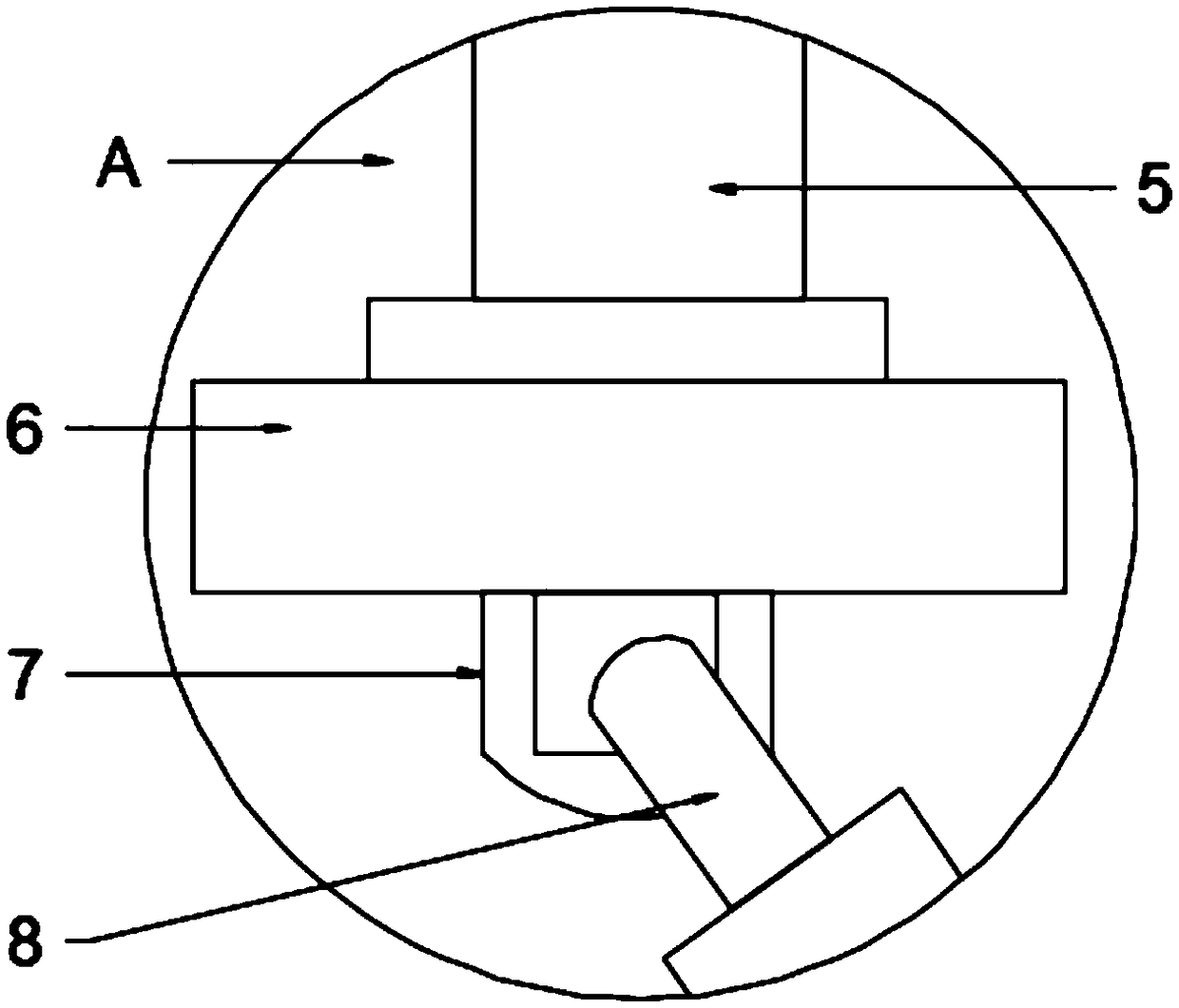

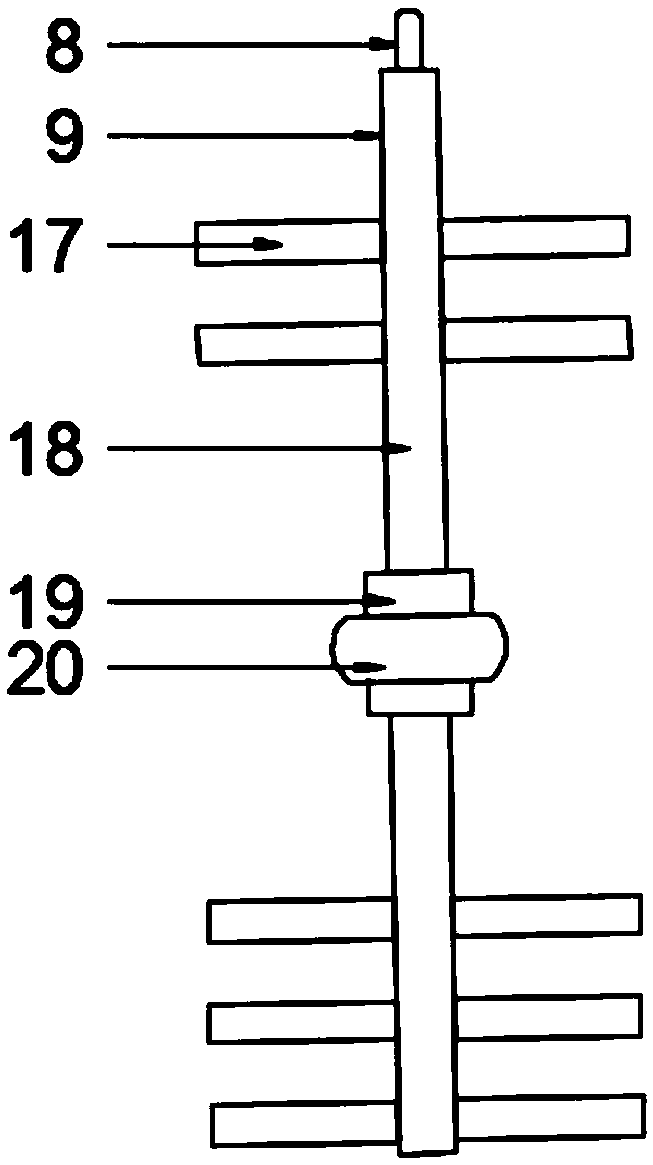

[0026] Further, the rocking rotation frame 9 is provided with a rotating shaft 18, a stirring rod 17 is installed on the rotating shaft 18, a limit sleeve 19 is sleeved at the center of the rotating shaft 18, and the limit sleeve 19 is externally fixed with a limit tube 20, The outer periphery of the position tube 20 is convex. The limit tube 20 is fixed to the fixed frame 10 by a spherical hinge. The fixed frame 10 is provided with a fixed tube. The inside of the fixed tube matches the limit tube 20 with a spherical cavity, and the fixed tube is connected through The tube is fixed inside the tank 11, the upper end of the rotating sh...

Embodiment 2

[0029] See Figure 1-5 , A stirring reaction device for producing carboxymethyl cellulose nitrate, which is added on the basis of embodiment 1: a fixing plate 131 is installed on the supporting leg 13, an inner support rod 132 is fixed at the lower end of the fixing plate 131, and the inner support The lower end of the rod 132 is inserted into the outer sleeve 134, the inner support rod 132 is sleeved with a spring 133, the upper end of the spring 133 is fixed on the fixing plate 131, and the lower end of the spring 133 is fixed on the outer sleeve 134.

[0030] The working principle of the present invention is: the stirring reaction device for producing carboxymethyl cellulose nitrate according to the present invention starts the motor 1 to drive the turntable 4 to rotate, and the turntable 4 drives the shaking and rotating frame 9 to revolve, and the shaking and rotating frame 9 is restricted by the limit tube 20. In the fixed frame 10, the shaking revolution is realized. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com