A multi-stage chopping and grinding machine

A grinding machine and grinding mechanism technology, applied in packaging, grain processing, large containers, etc., can solve the problems of low processing efficiency, many processing procedures, and inconvenient processing, and achieve high processing efficiency, good effect, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

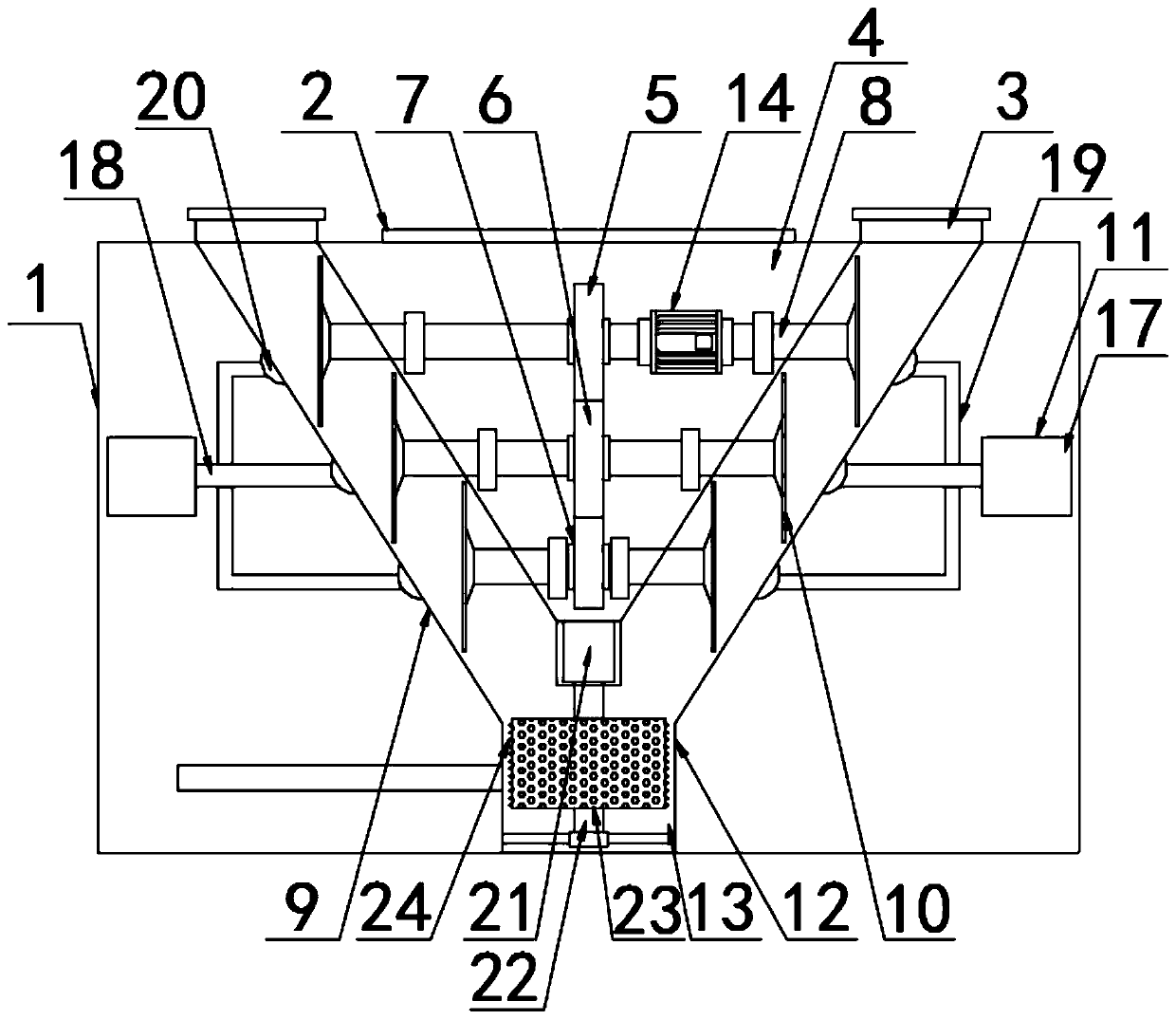

[0025] according to figure 1 The shown multi-stage chopping and grinding machine includes a box body 1, the top of the box body 1 is provided with a transparent top cover 2 and a feed port 3, and the feed port 3 is arranged on both sides of the transparent top cover 2, The inside of the box body 1 corresponding to the bottom of the transparent top cover 2 is provided with a control cavity 4, and the inside of the control cavity 4 is provided with an upper gear 5, a middle gear 6 and a lower gear 7, and the upper gear 5, the middle gear 6 and the lower gear Both sides of the gear 7 are provided with rotating shafts 8 , and the inside of the box 1 corresponding to the bottom of the feed port 3 is provided with a shredding pipe 9 , and the inside of the shredding pipe 9 is provided with a blade 10 , and the blade 10 is perpendicular to the rotating shaft 8 Setting, on the one hand, prevent the material from directly hitting the blade 10, causing damage to the blade 10; on the oth...

Embodiment 2

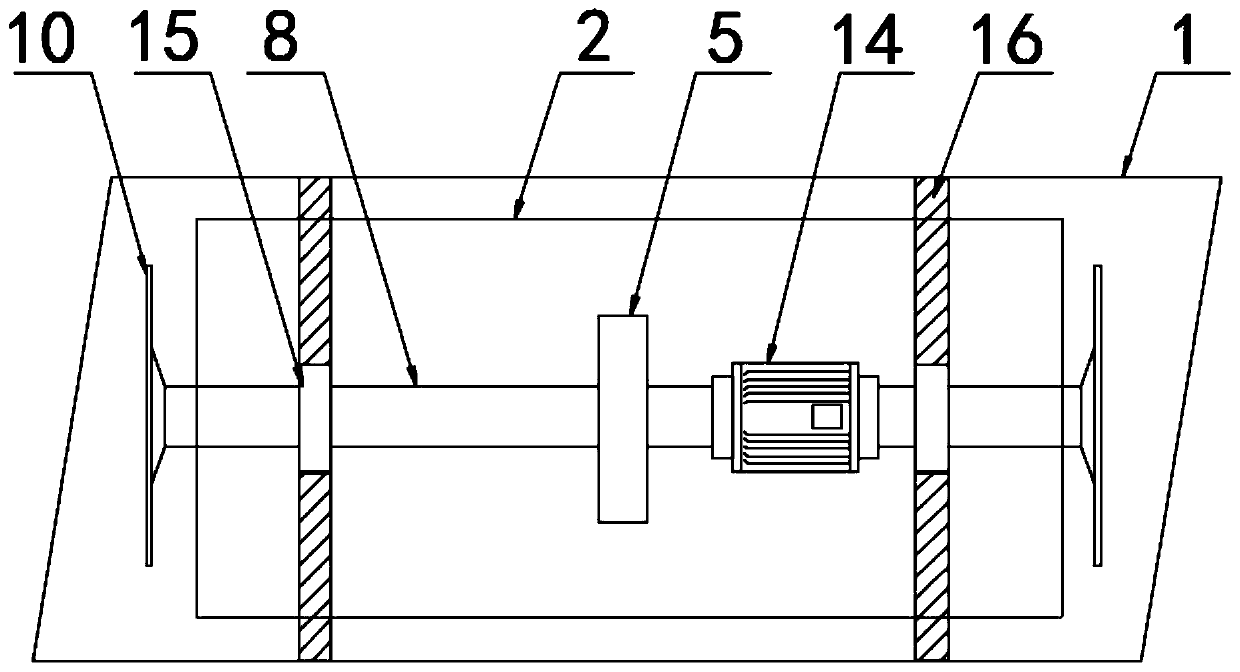

[0028] according to figure 2 In the shown multi-stage chopping and grinding machine, the upper gear 5 is provided with a biaxial motor 14 on one side, and the biaxial motor 14 is fixedly connected with the rotating shaft 8, which can drive the rotating shaft 8 on both sides to rotate at the same time. The materials inside the first shredding pipeline 9 are shredded at the same time. The shaft 8 is sheathed with a bearing 15. The front and rear sides of the bearing 15 are provided with a support rod 16, and the support rod 16 is fixed to the inner wall of the control chamber 4. connected to facilitate the support of the rotating shaft 8;

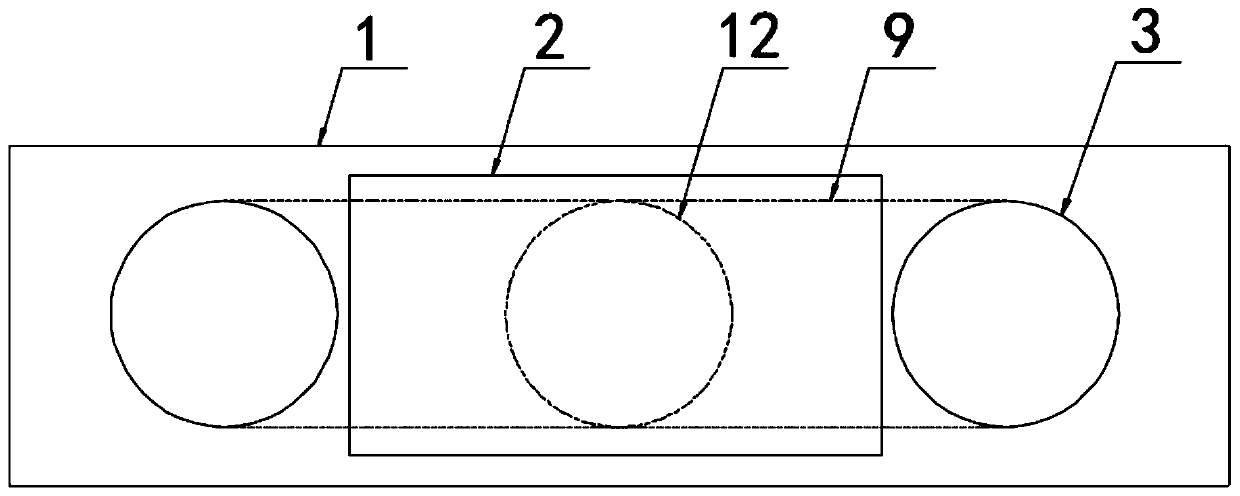

[0029] according to figure 1 and image 3 As shown in a multi-stage chopping and grinding machine, the chopping pipeline 9 is arranged in an inclined shape, and the two chopping pipelines 9 are arranged in a V shape, and the cross sections of the chopping pipeline 9 and the grinding pipeline 12 are all set It is circular, and the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com