Electronic component shell injection molding device

A technology for electronic components and casings, which is applied in the field of injection molding devices for electronic components casings, can solve problems such as waste of labor and complicated use, and achieve the effect of speeding up the work process and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

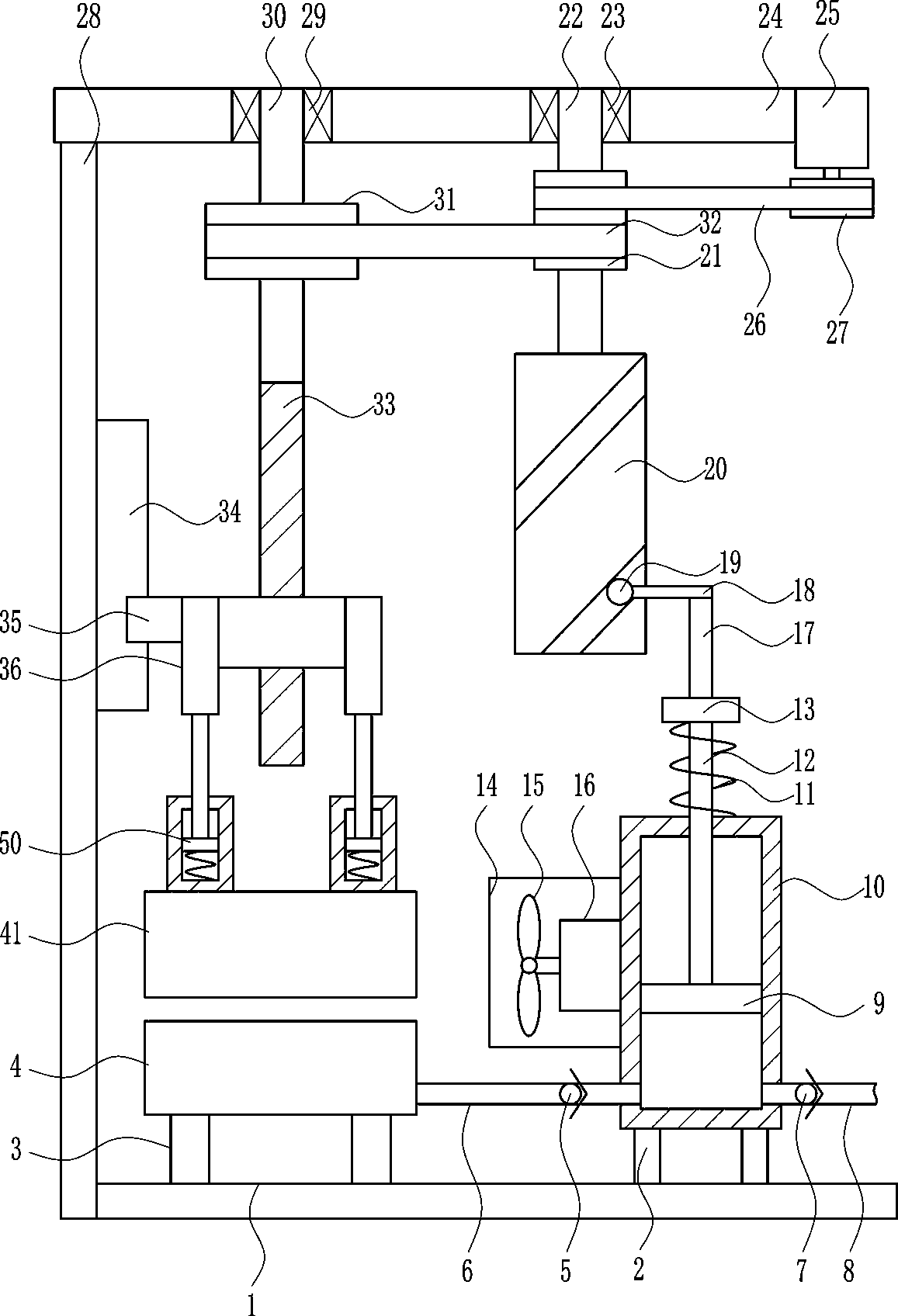

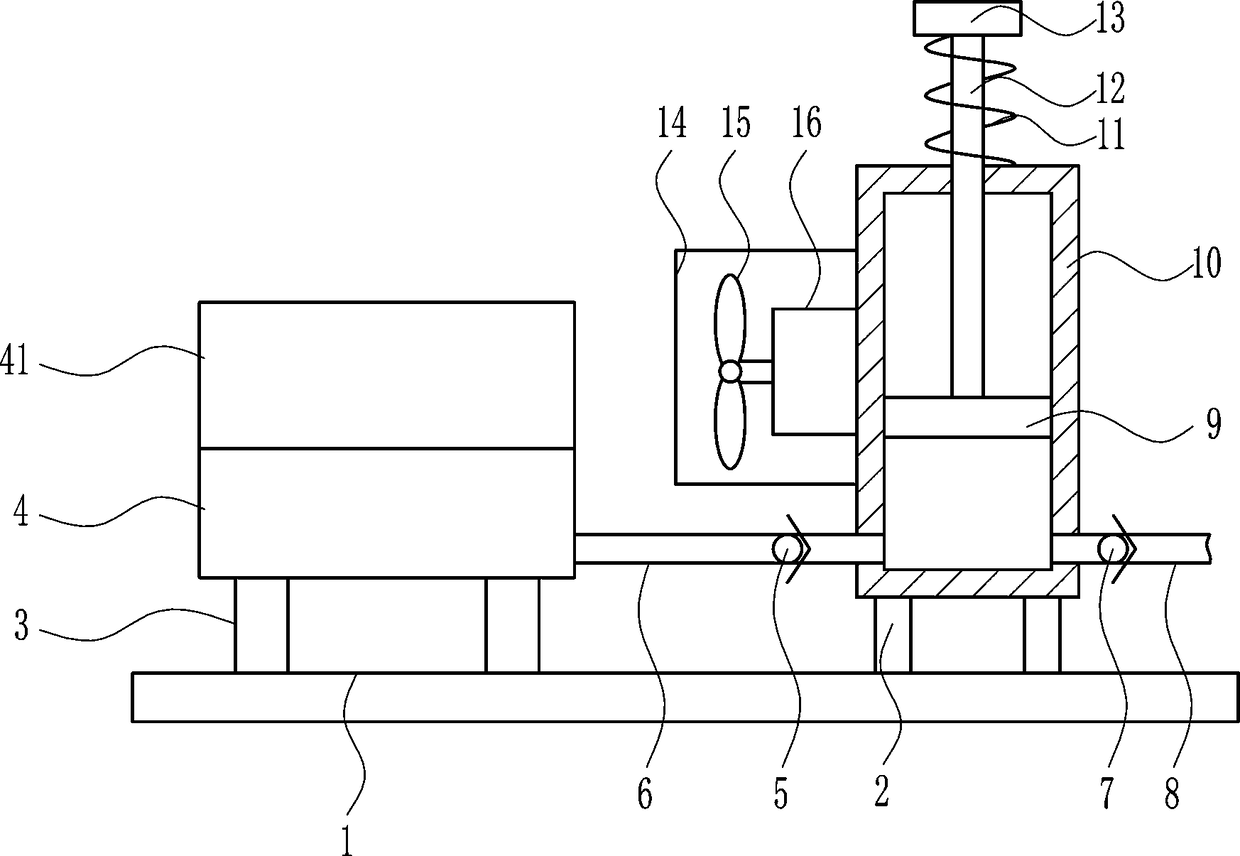

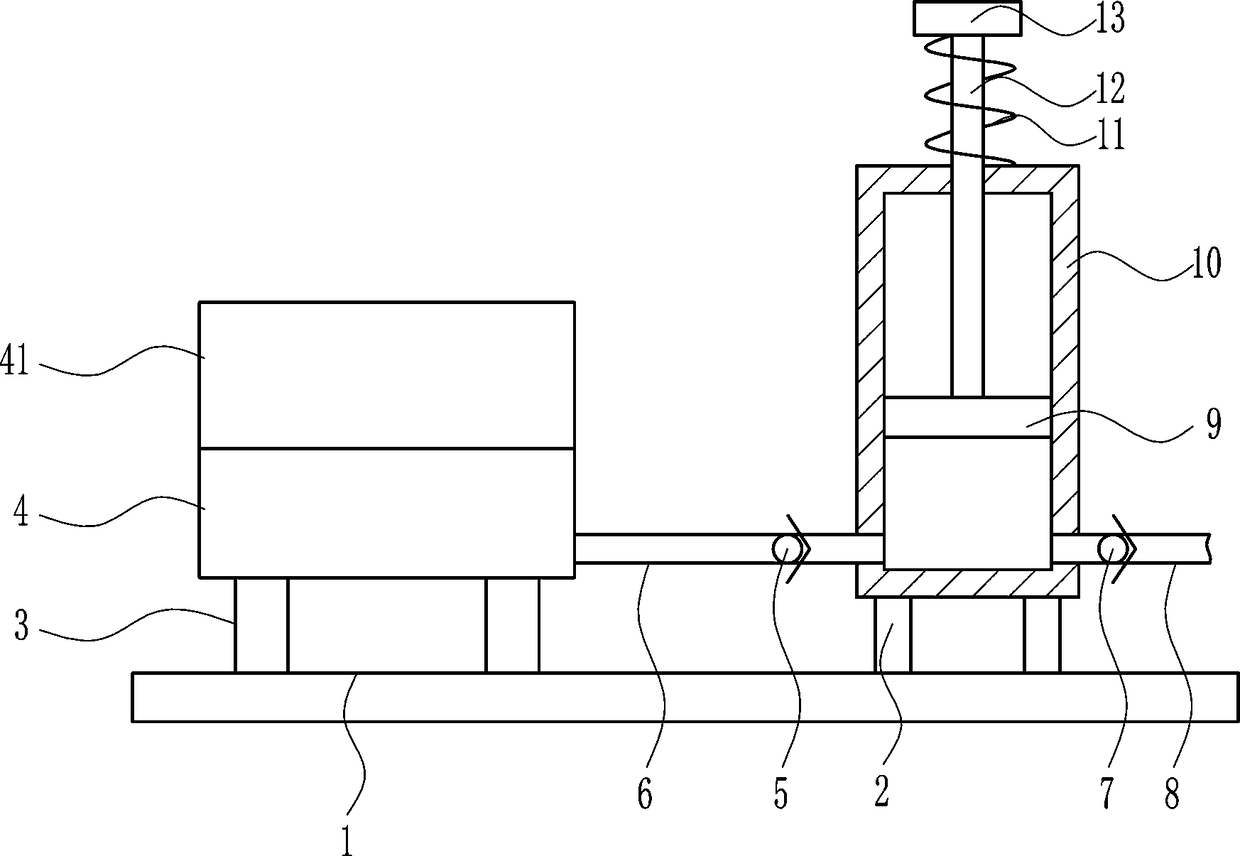

[0027] An injection molding device for an electronic component shell, such as Figure 1-6 As shown, it includes a base 1, a first support rod 2, a second support rod 3, a lower mold 4, a first one-way valve 5, a discharge pipe 6, a second one-way valve 7, a feed pipe 8, and a piston 9 , the cylinder block 10, the first spring 11, the lifting rod 12, the connecting plate 13 and the upper mold 41, the upper part of the base 1 is sequentially installed with the second supporting rod 3 and the first supporting rod 2 from left to right, and the upper part of the second supporting rod 3 The lower mold 4 is installed, the upper mold 41 is placed on the upper part of the lower mold 4, the cylinder body 10 is installed on the top of the first support rod 2, the discharge pipe 6 is installed on the left side of the cylinder body 10, and the first unit is installed in the discharge pipe 6. Directional valve 5, the left end of the discharge pipe 6 is connected to the lower mold 4, the rig...

Embodiment 2

[0029] An injection molding device for an electronic component shell, such as Figure 1-6As shown, it includes a base 1, a first support rod 2, a second support rod 3, a lower mold 4, a first one-way valve 5, a discharge pipe 6, a second one-way valve 7, a feed pipe 8, and a piston 9 , the cylinder block 10, the first spring 11, the lifting rod 12, the connecting plate 13 and the upper mold 41, the upper part of the base 1 is sequentially installed with the second supporting rod 3 and the first supporting rod 2 from left to right, and the upper part of the second supporting rod 3 The lower mold 4 is installed, the upper mold 41 is placed on the upper part of the lower mold 4, the cylinder body 10 is installed on the top of the first support rod 2, the discharge pipe 6 is installed on the left side of the cylinder body 10, and the first unit is installed in the discharge pipe 6. Directional valve 5, the left end of the discharge pipe 6 is connected to the lower mold 4, the righ...

Embodiment 3

[0032] An injection molding device for an electronic component shell, such as Figure 1-6 As shown, it includes a base 1, a first support rod 2, a second support rod 3, a lower mold 4, a first one-way valve 5, a discharge pipe 6, a second one-way valve 7, a feed pipe 8, and a piston 9 , the cylinder block 10, the first spring 11, the lifting rod 12, the connecting plate 13 and the upper mold 41, the upper part of the base 1 is sequentially installed with the second supporting rod 3 and the first supporting rod 2 from left to right, and the upper part of the second supporting rod 3 The lower mold 4 is installed, the upper mold 41 is placed on the upper part of the lower mold 4, the cylinder body 10 is installed on the top of the first support rod 2, the discharge pipe 6 is installed on the left side of the cylinder body 10, and the first unit is installed in the discharge pipe 6. Directional valve 5, the left end of the discharge pipe 6 is connected to the lower mold 4, the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com