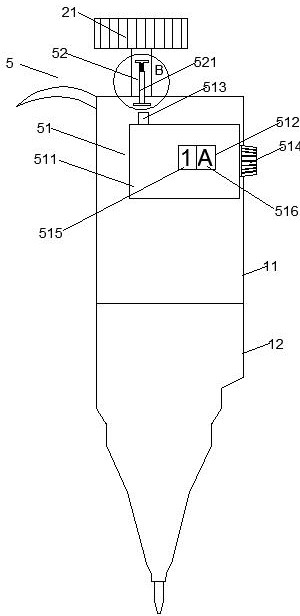

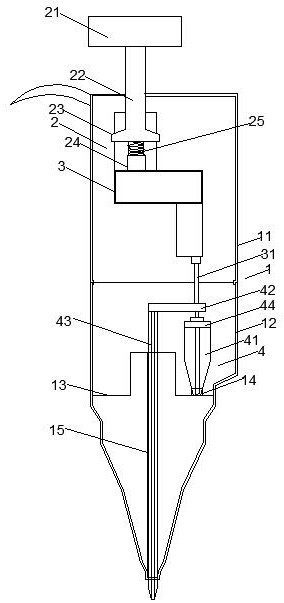

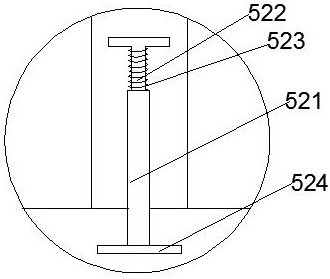

Pipetting device suitable for continuous sample adding

A liquid pipetting device and push device technology, which is applied to laboratory containers, measuring tubes/pipettes, chemical instruments and methods, etc., can solve the problem of forgetting the number of times of adding samples, consuming the operator's energy, and the process of adding samples. Discontinuity and other problems, to achieve the effect of simple structure, convenient sample adding operation, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0036] Sample plates with 96-hole slots are often used in laboratories and systematic cultivation processes. The 96-hole plate used in the laboratory is small in size and is mainly used for large-scale testing experiments; the 96-hole plate used in cultivation has a larger size and can be used In the process of seedling cultivation, in order to study the influence of different nutritional elements on the growth of seedlings and to cultivate high-quality plant varieties, after planning, it is often necessary to add liquid cultures containing different elements to different wells on the plate during the cultivation process. Do big data comparative analysis of reagents to observe its impact on plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com