Anti-falling preparation device for flame-retardant material based on fireproof coating

A flame-retardant material and fire-resistant coating technology, applied to the surface coating liquid device, lamination device, coating, etc., can solve the problems of fire-resistant coating overflow, glass fiber cloth falling off, cumbersome steps, etc., to speed up the work process , to ensure integrity, to reduce the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

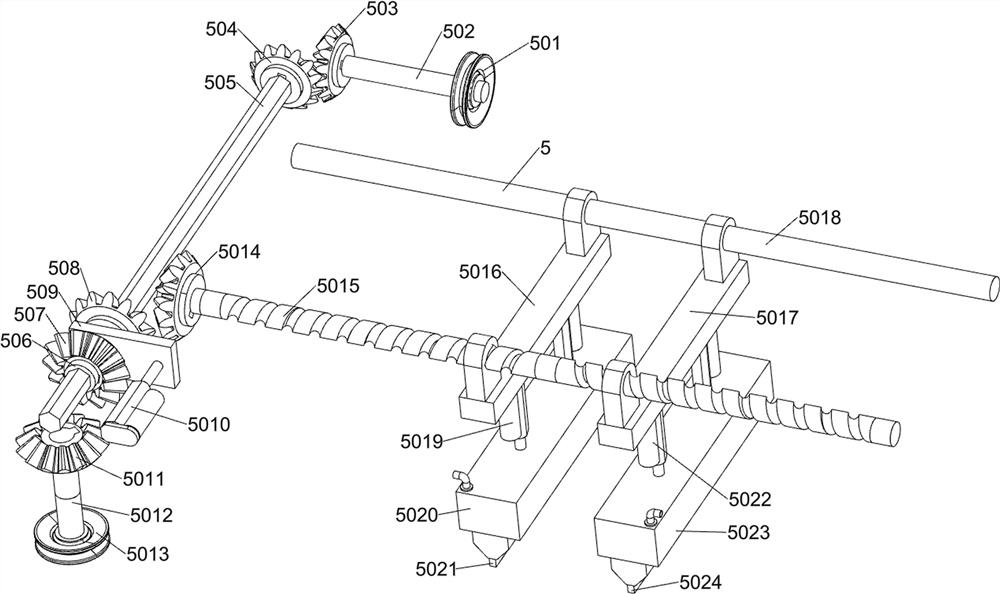

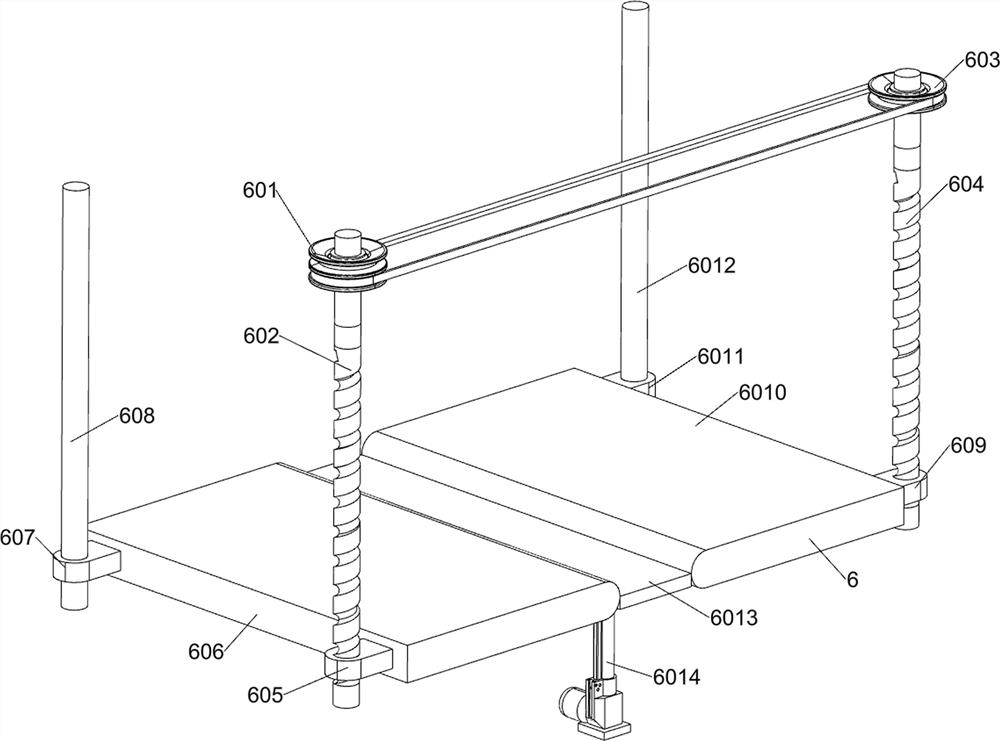

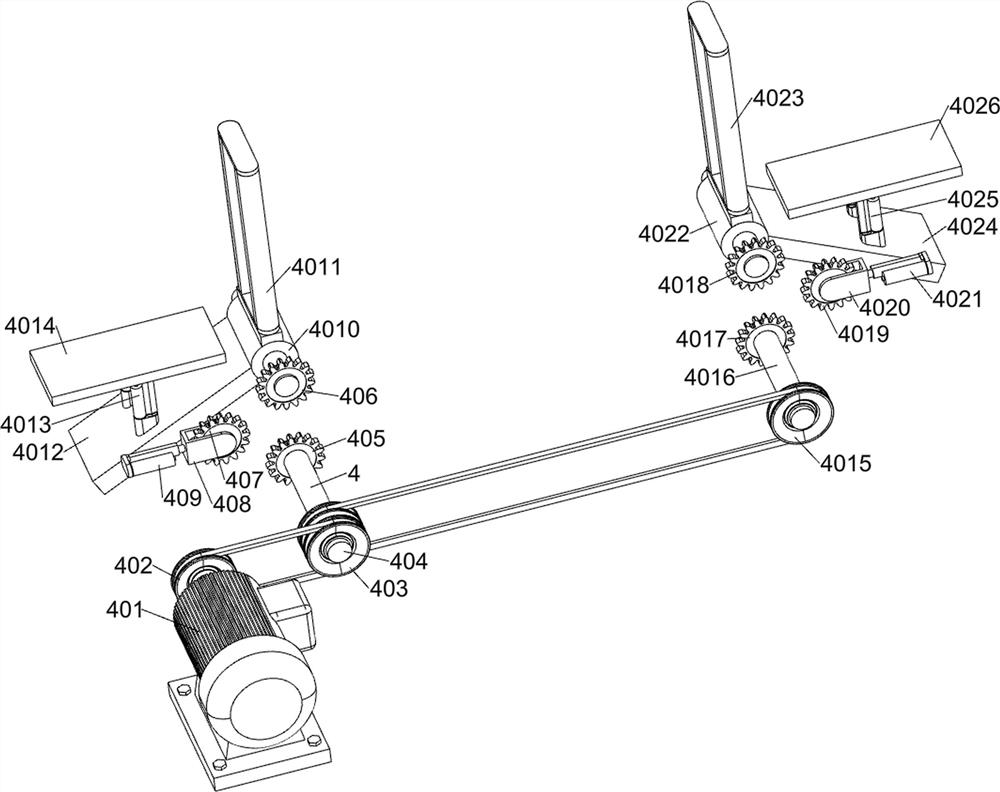

[0029] A flame retardant material anti-shedding preparation device based on fire retardant coating, such as Figure 1-9 As shown, it includes a fixed frame plate 1, an elevated plate 2, a display control panel 3, a fixed bottom pressing system 4, a coating system 5 and a double-sided laminating system 6; two sets of elevated plates 2 are arranged under the fixed frame plate 1 ; The fixed frame plate 1 is connected with the display control panel 3; the fixed frame plate 1 is connected with the fixed bottom pressing system 4; the fixed frame plate 1 is connected with the coating system 5; the fixed frame plate 1 is connected with the double-sided bonding system 6 ; The fixed bottom system 4 is connected to the paint system 5 ; the paint system 5 is connected to the double-sided bonding system 6 .

[0030] When using this device, the device is horizontally fixed on the required working plane, connected to an external power supply, and the operator conducts overall deployment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com