COD (chemical oxygen demand) control method for SBR (sequencing batch reactor) biochemical reaction tank

A biochemical reaction and control method technology, applied in chemical instruments and methods, water treatment parameter control, sustainable biological treatment, etc., can solve the problems affecting the control accuracy and poor control effect of COD control methods, and achieve high COD control accuracy. , the effect of good control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

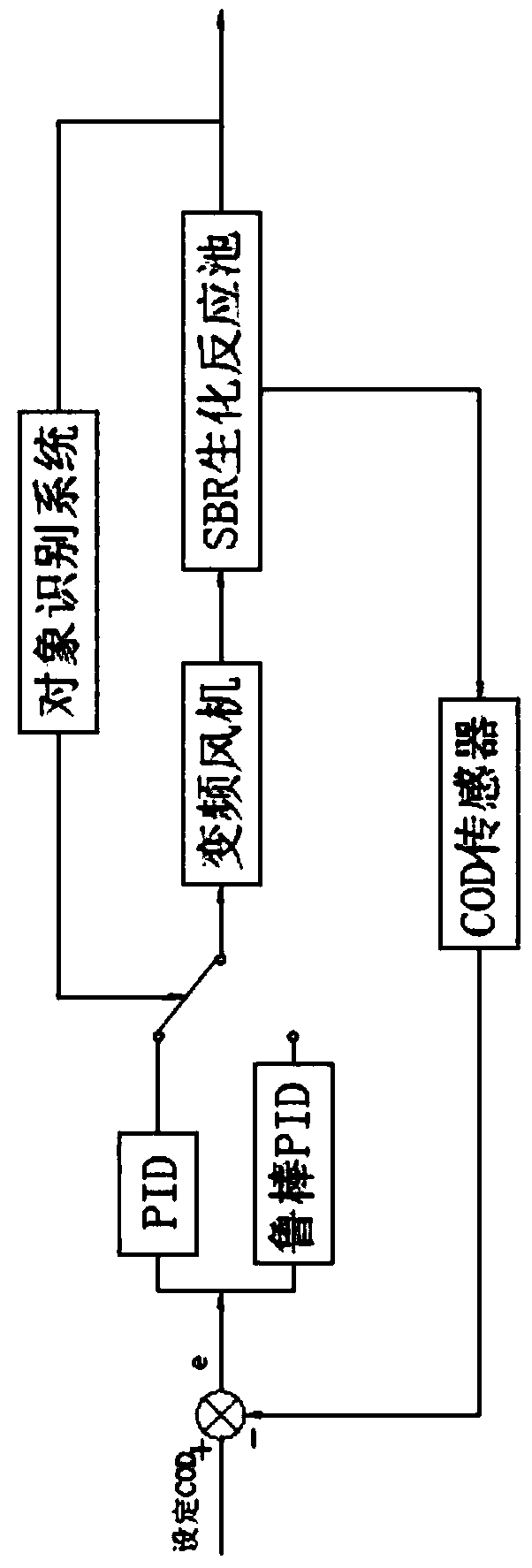

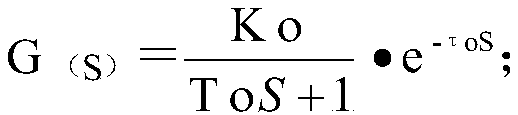

[0018] like figure 1 As shown, the present embodiment provides a SBR biochemical reaction tank system adopting the above-mentioned COD control method, including a SBR biochemical reaction tank; a frequency conversion fan; an object identification system for judging the current SBR biochemical reaction tank working condition; a real-time monitoring SBR A COD sensor for the sewage COD value in the biochemical reaction tank; a subtractor that inputs the set COD value of the sewage and the real-time feedback COD value of the COD sensor, and uses the feedback signal summation to realize the subtraction operation and output; an input subtractor The output electrical signal control The PID controller of the frequency conversion fan and a robust PID controller that also inputs the output electrical signal of the subtractor to control the frequency conversion fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com