Low temperature resistant elastomer resin material suitable for polar and extremely cold regions and preparation method thereof

A technology of low temperature resistant elastomer and resin material, which is applied in the field of low temperature resistant elastomer resin material and its preparation, can solve the problems of fracture and insufficient low temperature resistance of tent floor mats, and achieves good weather resistance, outstanding mechanical properties, high resistance to low temperature and so on. Excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the low-temperature-resistant elastomeric resin material suitable for polar and extremely cold regions comprises the following process steps:

[0025] a. Preparation of primary mixture: 2,4-dichlorobenzoyl peroxide, dibenzothiazole disulfide, bis(1,5-pentylidene)thiuram tetrasulfide, ethylphenyl disulfide Add zinc carbamate and 4,4'-dimorpholine disulfide into the mixer, and mix evenly to obtain the primary mixture;

[0026] b. Dynamic vulcanization: first add block-type ethylene octene copolymer, hydrogenated styrene-butadiene block copolymer, EPDM rubber, and random copolymerized polypropylene into the internal mixer for banburying, and then add The primary mixture obtained in step a continues banburying to obtain a blend;

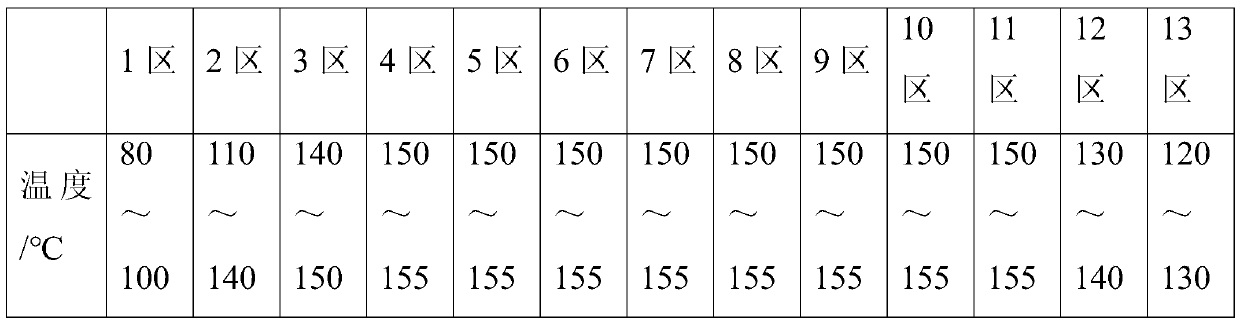

[0027] c. Extrusion granulation: crush and pelletize the blend prepared in step b, mix it with polystyrene, methyl methacrylate monomer and silane coupling agent, add it into a twin-screw extruder, and extrude After bei...

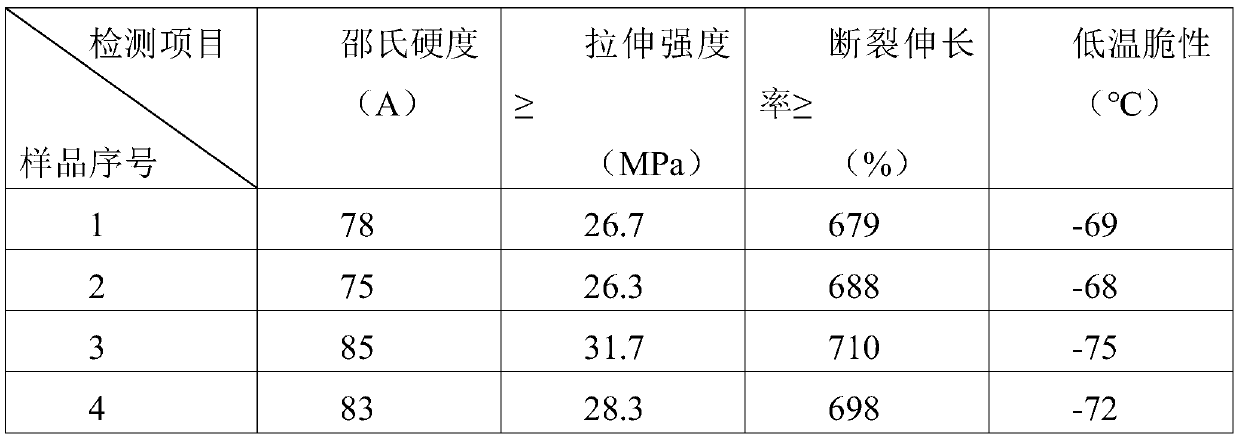

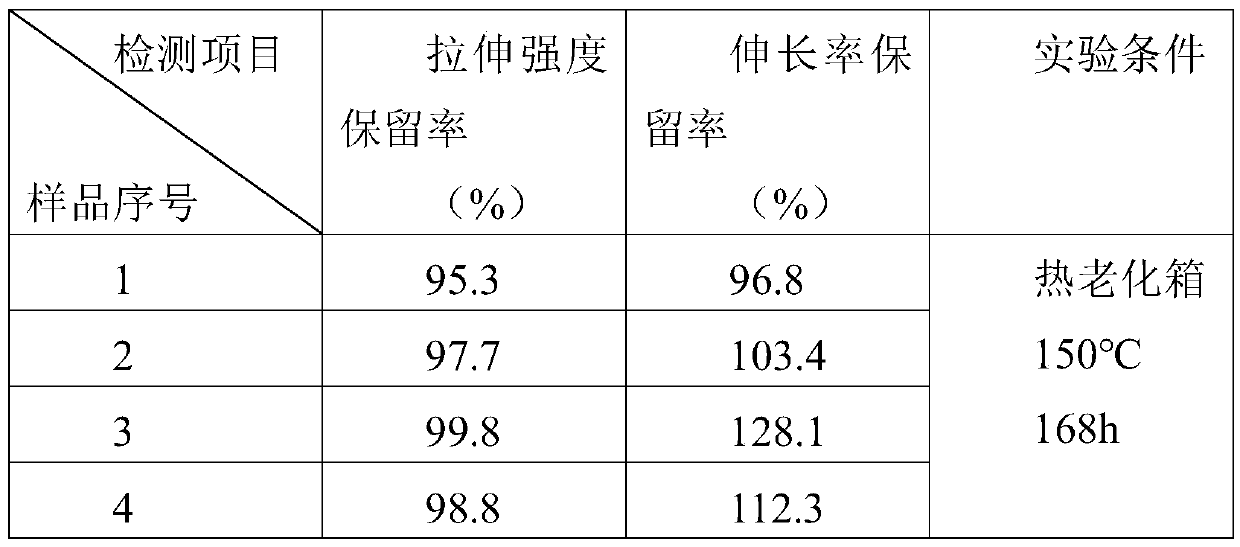

Embodiment 1

[0037] A low-temperature-resistant elastomeric resin material suitable for polar and extremely cold regions, which includes the following raw materials calculated in parts by weight:

[0038] 20 parts of block type ethylene octene copolymer, 15 parts of hydrogenated styrene-butadiene block copolymer, 20 parts of EPDM rubber, 10 parts of random copolymer polypropylene, 7 parts of polystyrene, 2,4 - 0.5 parts of dichlorobenzoyl peroxide, 0.5 parts of dibenzothiazole disulfide, 1 part of bis(1,5-pentylidene) thiuram tetrasulfide, 0.2 parts of zinc ethylphenyl dithiocarbamate , 1 part of 4,4'-dimorpholine disulfide, 1 part of methyl methacrylate monomer, and 1.6 parts of γ-aminopropyltriethoxysilane.

[0039] The preparation method of the low-temperature-resistant elastomeric resin material suitable for polar and extremely cold regions comprises the following process steps:

[0040] a. Preparation of primary mixture: 2,4-dichlorobenzoyl peroxide, dibenzothiazole disulfide, bis(1,...

Embodiment 2

[0046] A low-temperature-resistant elastomeric resin material suitable for polar and extremely cold regions, which includes the following raw materials calculated in parts by weight:

[0047] 30 parts of block type ethylene octene copolymer, 25 parts of hydrogenated styrene-butadiene block copolymer, 25 parts of EPDM rubber, 15 parts of random copolymerized polypropylene, 10 parts of polystyrene, 2,4 -0.8 parts of benzoyl dichloroperoxide, 1 part of dibenzothiazole disulfide, 1.5 parts of bis(1,5-pentylidene)thiuram tetrasulfide, 0.5 parts of zinc ethylphenyl dithiocarbamate , 1.2 parts of 4,4'-dimorpholine disulfide, 2 parts of methyl methacrylate monomer, and 2 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0048] The preparation method of the low-temperature-resistant elastomeric resin material suitable for polar and extremely cold regions comprises the following process steps:

[0049] a. Preparation of primary mixture: 2,4-dichlorobenzoyl peroxide, dibenzothi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap