Inclusion control method for SWRH82B steel produced by carbon-free steel ladle

A carbon-free ladle and control method technology, applied in the field of metallurgy, can solve problems such as the increase of brittle inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

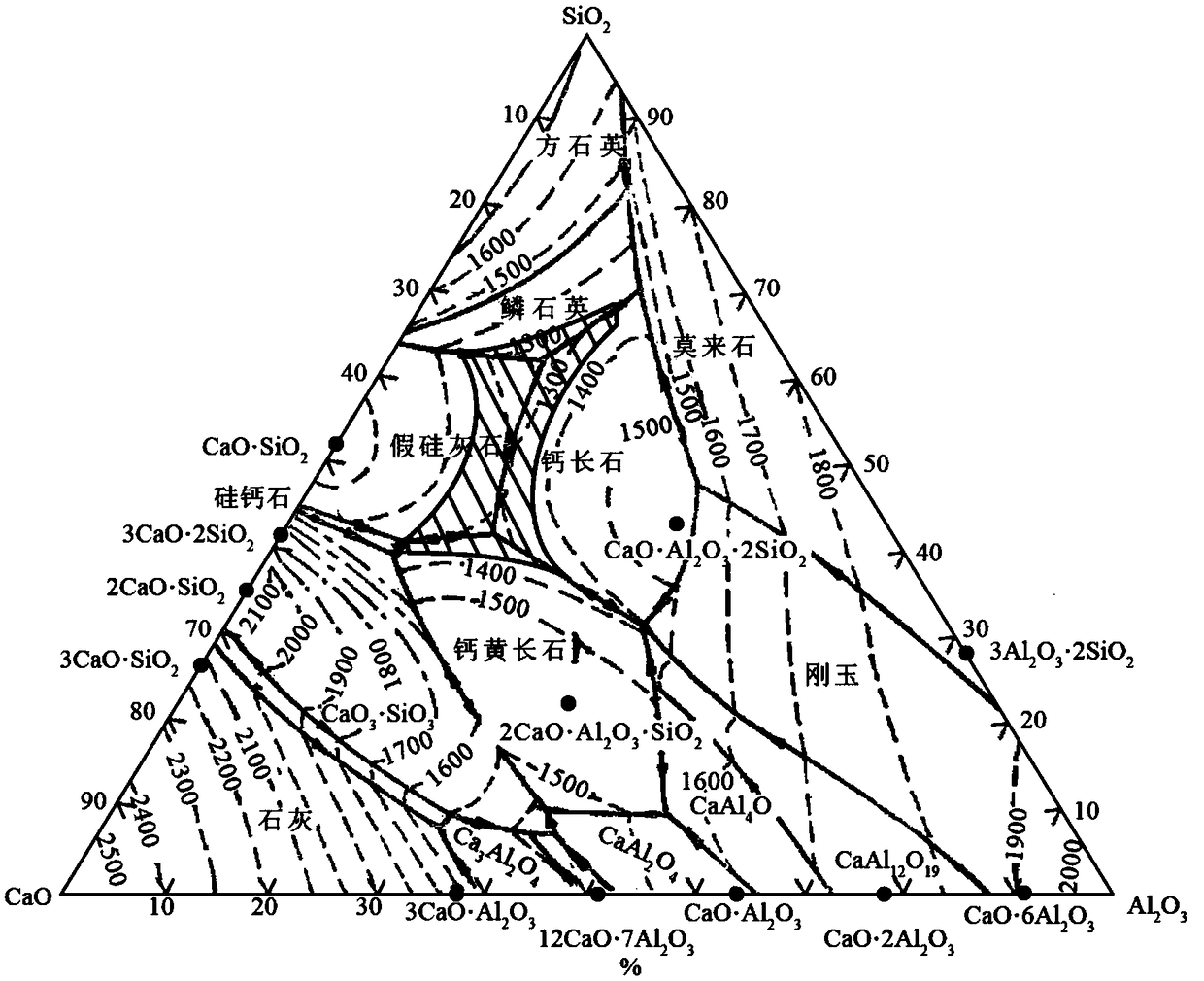

Method used

Image

Examples

Embodiment 1

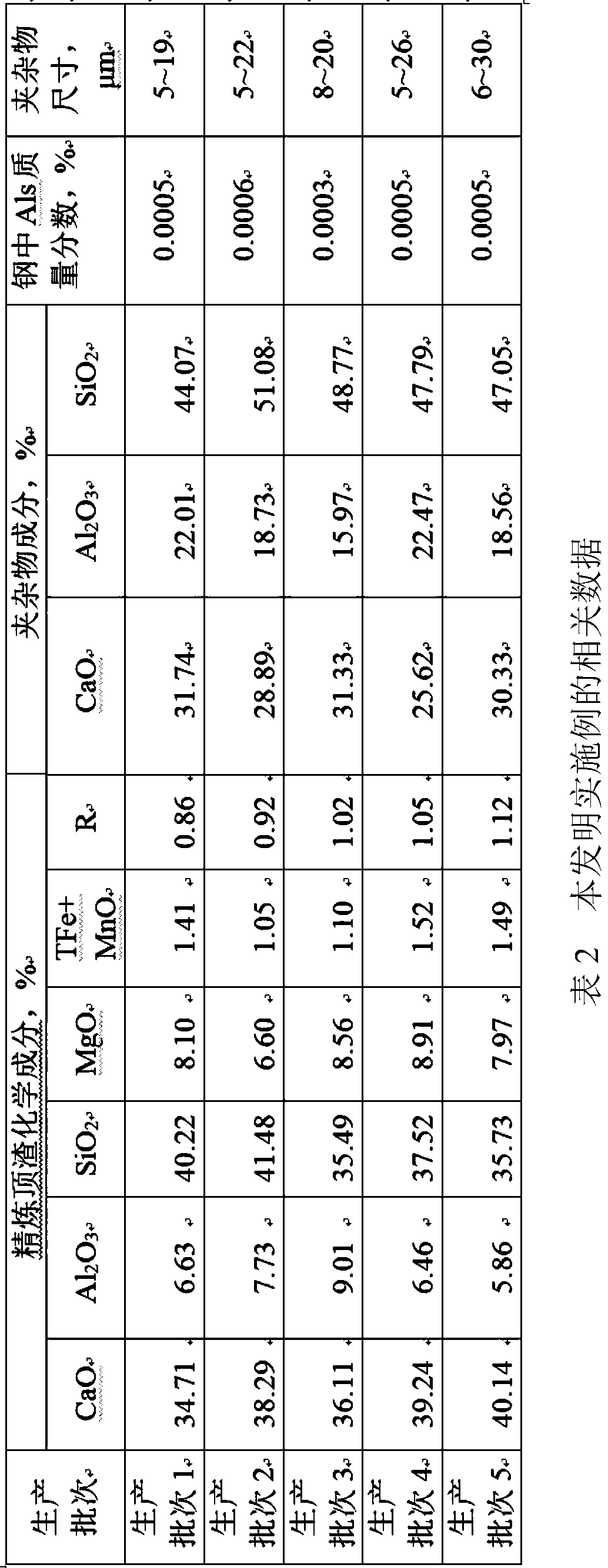

[0033] Example 1: Target composition of refining top slag, calculated by mass fraction, in %: CaO: 34.71; Al2O3: 6.63; SiO2: 40.22; MgO: 8.10; TFe+MnO≤1.41; Alkalinity R: 0.86. The inclusion composition is calculated by mass fraction in %: CaO: 31.74, Al 2 o 3 : 22.01, SiO 2 : 44.07, Als in steel is calculated by mass fraction: 0.0005, unit is %, inclusion size, 5 ~ 19μm.

Embodiment 2

[0034] Example 2: The target composition of refining top slag is calculated by mass fraction, and the unit is %: CaO: 38.29; Al2O3: 7.73; SiO2: 41.48; MgO: 6.60; TFe+MnO≤1.05; Alkalinity R: 0.92. The inclusion composition is calculated by mass fraction in %: CaO: 28.89, Al 2 o 3 : 18.73, SiO 2 : 51.08, calculated by mass fraction of Als in steel: 0.0006, unit is %, inclusion size, 5 ~ 22μm.

Embodiment 3

[0035] Example 3: Target composition of refining top slag, calculated by mass fraction, in %: CaO: 36.11; Al2O3: 9.01; SiO2: 35.49; MgO: 8.56; TFe+MnO≤1.10; Alkalinity R: 1.02. The inclusion composition is calculated by mass fraction in %: CaO: 31.33, Al 2 o 3 : 15.97, SiO 2 : 48.77, Als in steel calculated by mass fraction: 0.0003, unit is %, inclusion size, 8 ~ 20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com