Special cooling device with cold water circulation effect and used for metal production quenching

A cold water circulation and cooling device technology, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problem that the cooling device does not have the function of cold water circulation, and achieve the effect of saving time and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

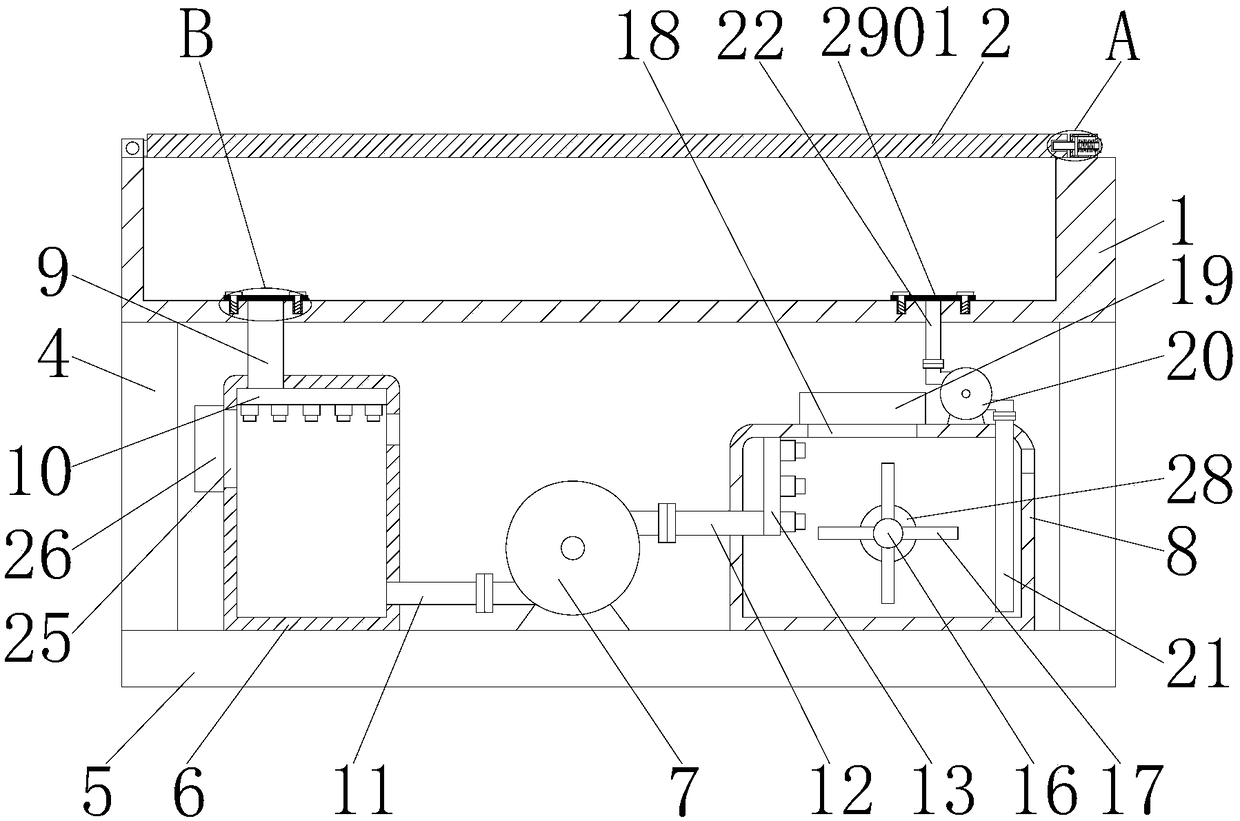

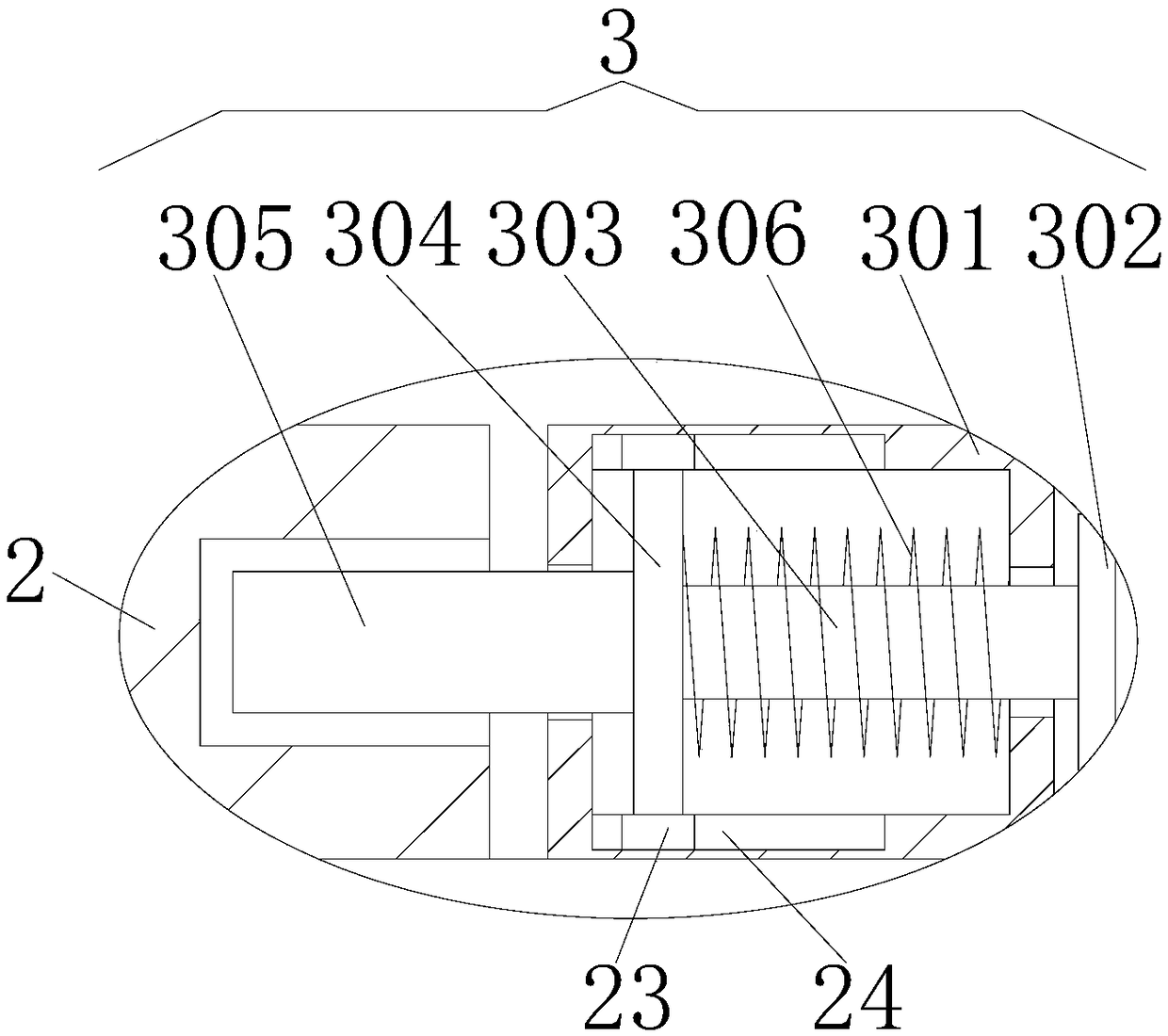

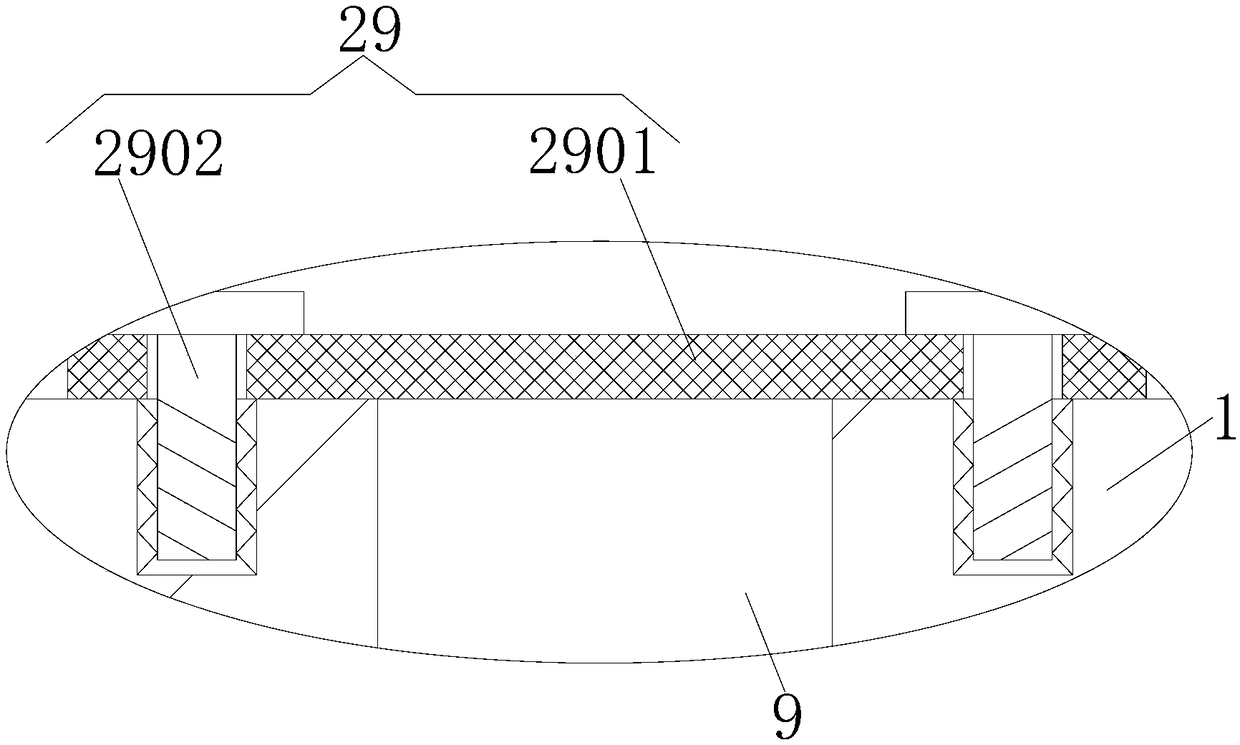

[0031] Embodiment 2: The difference from Embodiment 1 is that the limit mechanism 3 includes a transmission box 301, a disk 302 is arranged on the right side of the transmission box 301, a pull rod 303 is fixedly connected to the left side of the disk 302, and the left end of the pull rod 303 runs through The transmission box 301 extends to the inside of the transmission box 301 and is fixedly connected with a moving column 304. The top and bottom of the moving column 304 are slidingly connected with the top and bottom of the inner wall of the transmission box 301 respectively, and the left side of the moving column 304 is fixedly connected with a clamping rod 305. , the left end of the clamping rod 305 runs through the cover plate 2 and extends to the inside of the cover plate 2, the surface of the pull rod 303 is covered with a spring 306, the left end of the spring 306 is fixedly connected with the moving column 304, and the right end of the spring 306 is fixedly connected wi...

Embodiment 3

[0032] Embodiment 3: The difference from Embodiment 2 is that the top and bottom of the moving column 304 are fixedly connected with a slider 23, and the top and bottom of the inner wall of the transmission box 301 are provided with a chute 24, and the chute 24 and the slider 23 slide Connection, by setting the slider 23 and the chute 24, the slider 23 can be driven to move left and right when the moving column 304 moves left and right, thereby avoiding the contact between the moving column 304 and the transmission box 301, and preventing friction between the transmission box 301 and the moving column 304 Compared with the guide rail structure on the market, this structure can effectively prevent the friction between the transmission box 301 and the moving column 304, and does not occupy the internal space of the transmission box 301. The guide rail structure on the market is generally fixed inside the transmission box 301. Then move the moving column 304 to the inside of the g...

Embodiment 4

[0033] Embodiment 4: The difference with Embodiment 1 is that the top of the storage box 6 left side is provided with a through hole 25, and the left side of the through hole 25 is provided with a second exhaust fan 26, and the air outlet of the second exhaust fan 26 is connected with the through hole. 25 communicates, by setting the through hole 25 and the second exhaust fan 26, the user can open the second exhaust fan 26, the second exhaust fan 26 sends the cold wind into the storage box 6 through the through hole 25, and the storage box 6 is cooled by the cold wind. Compared with the market, there is no such structure. When the water is cooled, the structure is cooled by the second exhaust fan 26, which can save the subsequent cooling time and improve the cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com