Corrosion-resistant concrete structure of a sea-crossing bridge

A technology for concrete structures and sea-crossing bridges, used in bridges, bridge materials, bridge construction, etc., can solve the problems of damaged coatings, failure of anti-corrosion coatings, erosion of concrete and steel bars, etc., and achieve the effect of reducing damage and reducing damage to the bridge body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

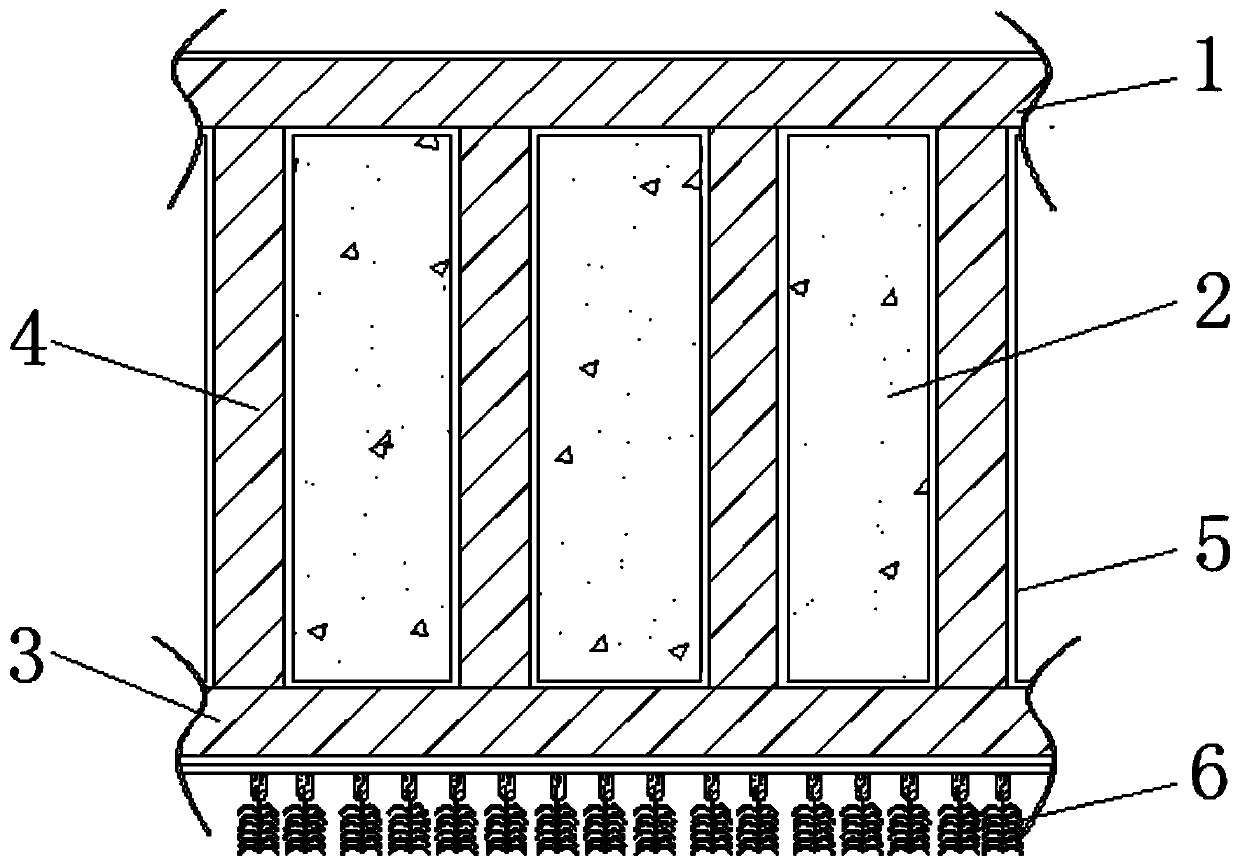

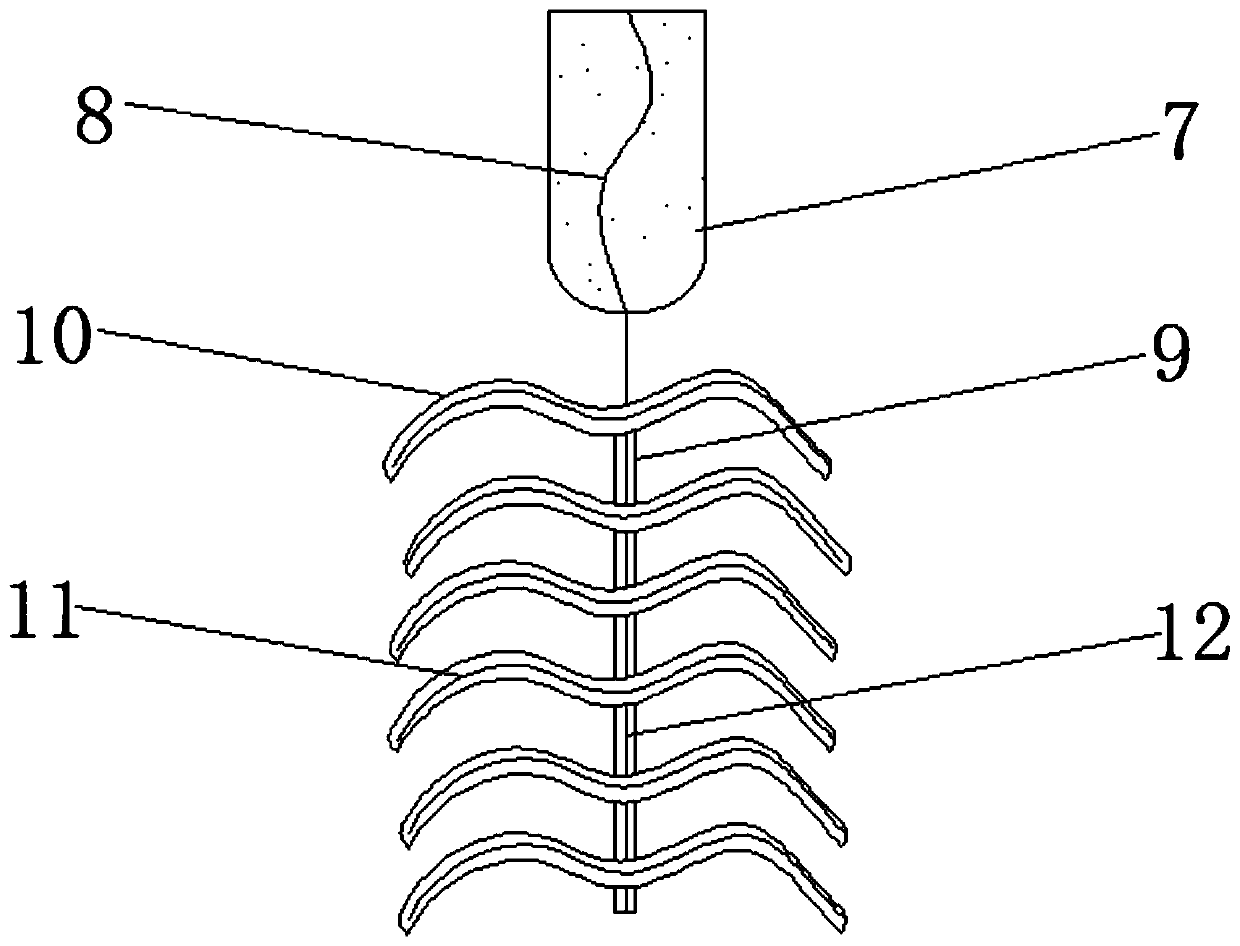

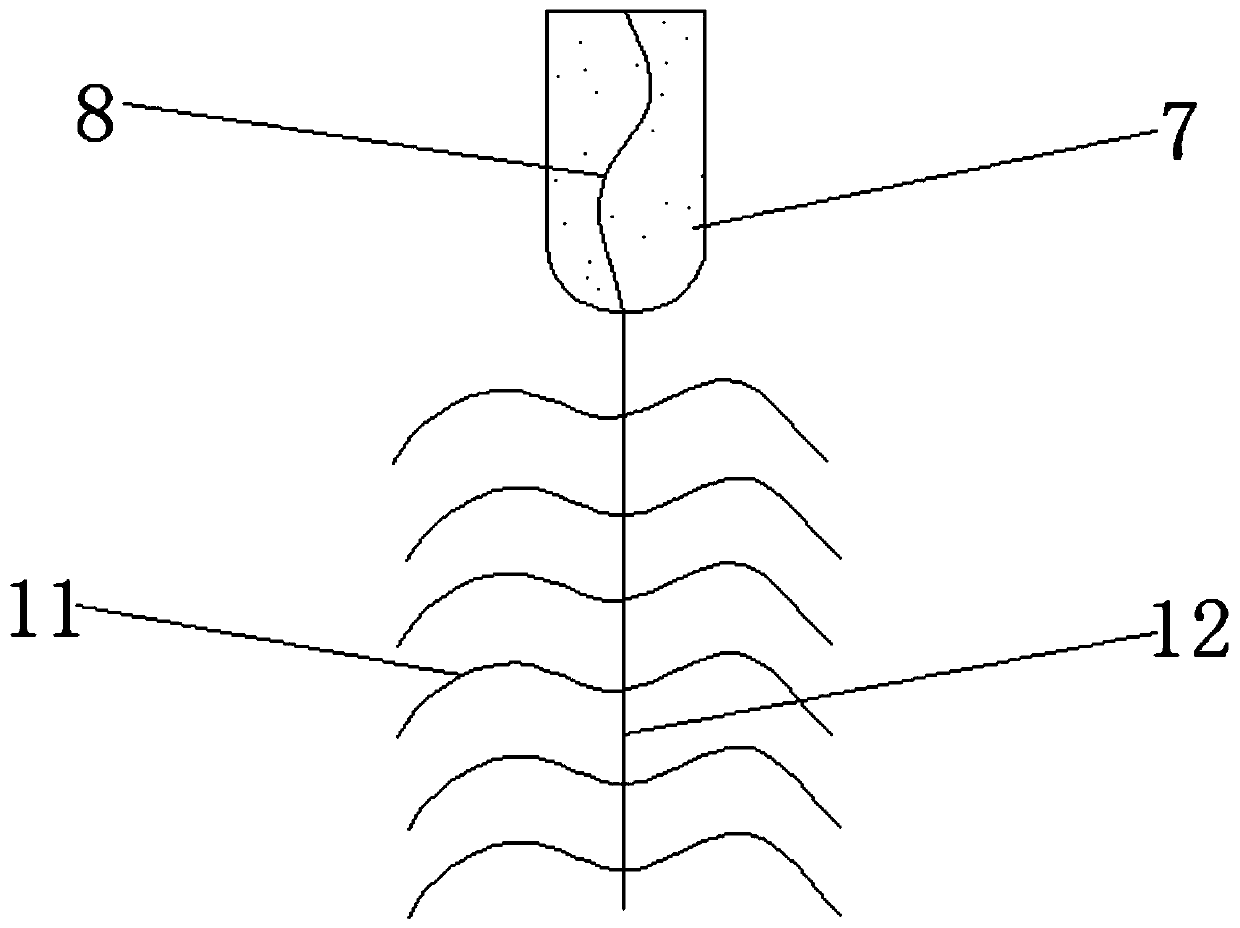

[0036] see Figure 1-4, an anti-corrosion concrete structure of a sea-crossing bridge, comprising concrete 2, a first reinforced steel plate 1 and a second reinforced steel plate 3 connected to the outer side of the concrete 2, and multiple reinforced steel plates 1 and 3 are connected between the first reinforced steel plate 1 and the second reinforced steel plate 3 The third reinforced steel plate 4, multiple third reinforced steel plates 4 separate the concrete 2 into multiple pieces, the concrete 2 is internally connected with multiple reinforced steel bars, and the surface of the multiple reinforced steel bars is coated with a coating 5 to strengthen the seismic and compressive strength of the bridge body , the lower end of the second reinforced steel plate 3 is coated with a coating 5, and the surface of the coating 5 is coated with an adhesive coating, the adhesive coating is elastic epoxy resin, and the viscosity is high, which improves the followability of the adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com