Height-adjustable breakwater and method

A technology for adjusting height and breakwaters, applied in the directions of breakwaters, jetties, embankments, etc., can solve the problem that the breakwater cannot meet the wind and waves of bad weather, and achieve the effect of ensuring safety, security and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

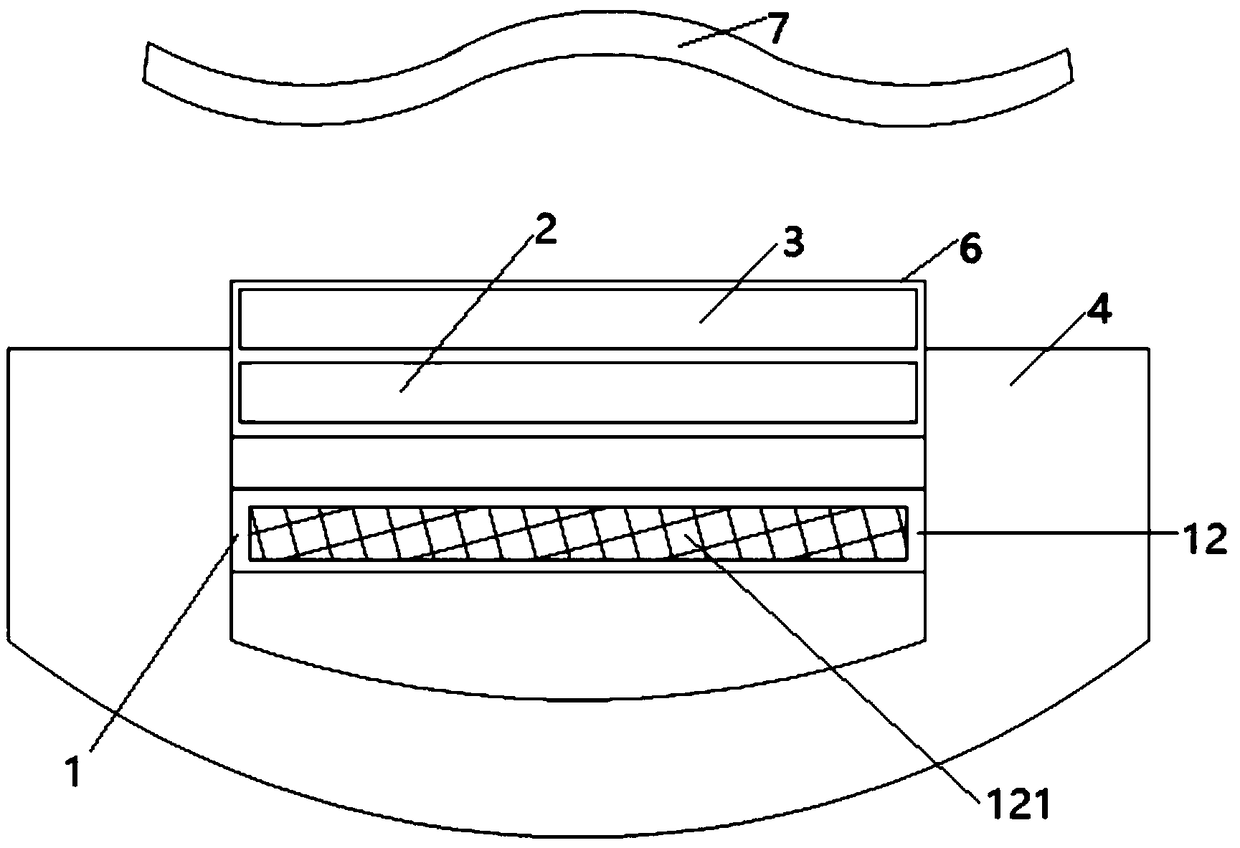

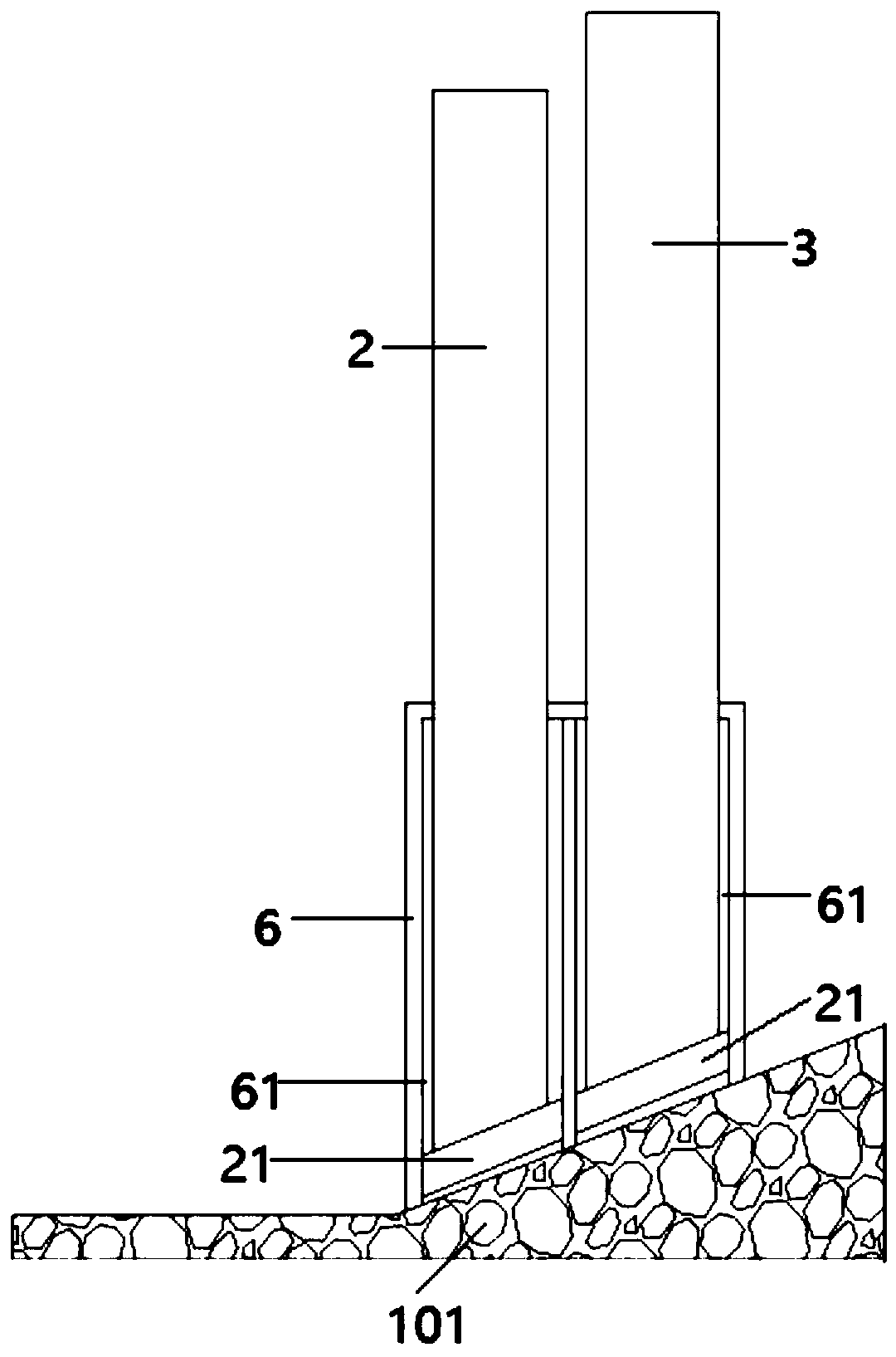

[0031] Such as figure 1 The illustrated embodiment is a height-adjustable breakwater, which includes a breakwater structure 1 located at the seaside, a first breakwater wall 2 behind the breakwater structure, and a second breakwater behind the first breakwater wall. Wave wall 3, be located at the water bag 4 in the groove of coast ground, be located at groove such as Figure 5 The cover plate 5 shown; the cover plate can slide up and down along the inner wall of the groove, such as image 3 As shown, both the first anti-wave wall and the second anti-wave wall are connected with the guide structure 6 located on the coast ground, and the guide structure includes two independent cavities 61 whose upper and lower ends are closed; the first anti-wave wall and the second anti-wave The lower ends of the anti-wave walls extend into two independent cavities respectively, the lower ends of the first anti-wave wall and the second anti-wave wall are provided with push plates 21, and the ...

Embodiment 2

[0037] Embodiment 2 includes all structure and method parts of embodiment 1, such as Figure 4 As shown, embodiment 2 also includes an auxiliary anti-wave wall 7 located behind the second anti-wave wall, the front surface and the rear surface of the auxiliary anti-wave wall are all wave-shaped; the bottom of the coast is provided with an accommodating groove for the auxiliary anti-wave wall 8. The lower part of the receiving groove is in communication with the air intake pipe 9, and the lower end of the auxiliary anti-wave wall is provided with a piston plate 10 which is slidingly and sealedly connected with the receiving groove. .

[0038] Also include the following steps:

[0039] The server obtains real-time weather forecast information through the Internet. If the weather forecast predicts that there will be a typhoon or a tsunami landing one hour after the current moment;

[0040]The controller controls the operation of the air pump to inflate the lower part of the cont...

Embodiment 3

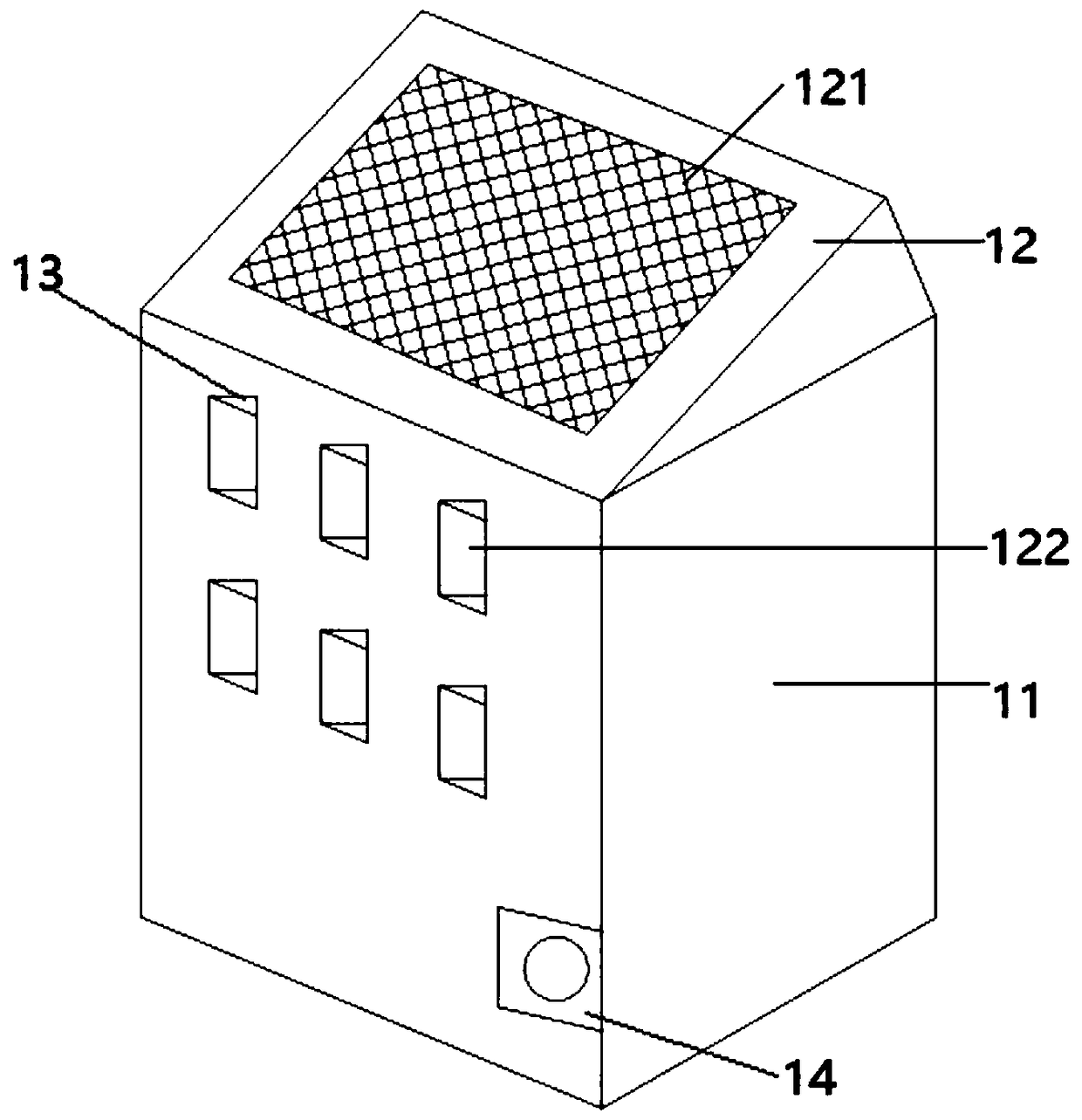

[0043] Embodiment 3 includes all structure and method parts of embodiment 1, as figure 2 As shown, the anti-wave structure of Embodiment 3 includes a rectangular housing 11, a filter cover 12 provided on the rectangular housing, 6 openings 13 provided on the front shell of the rectangular housing, and 6 openings 13 located at the lower part of the rectangular housing The water outlet 14; the water outlet is provided with a water wheel, and the rotating shaft of the water wheel is connected with the rotor of the generator through the transmission device; the filter cover plate is triangular, and the middle part of the filter cover plate is provided with a filter screen 121; each opening is provided with The overturning plate 122 can only be overturned to the inside of the rectangular housing, and each overturning plate is connected to the edge of the corresponding opening through a spring. Each overturning plate is provided with a sealing ring; each opening is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com