Method for installing post-installed steel beam of basement roof frame

A basement roof and installation method technology, which is applied to the processing of building materials, construction, building construction, etc., can solve the problems of large amount of chiseling and removal, and achieve the effects of shortening the installation period, easy operation, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

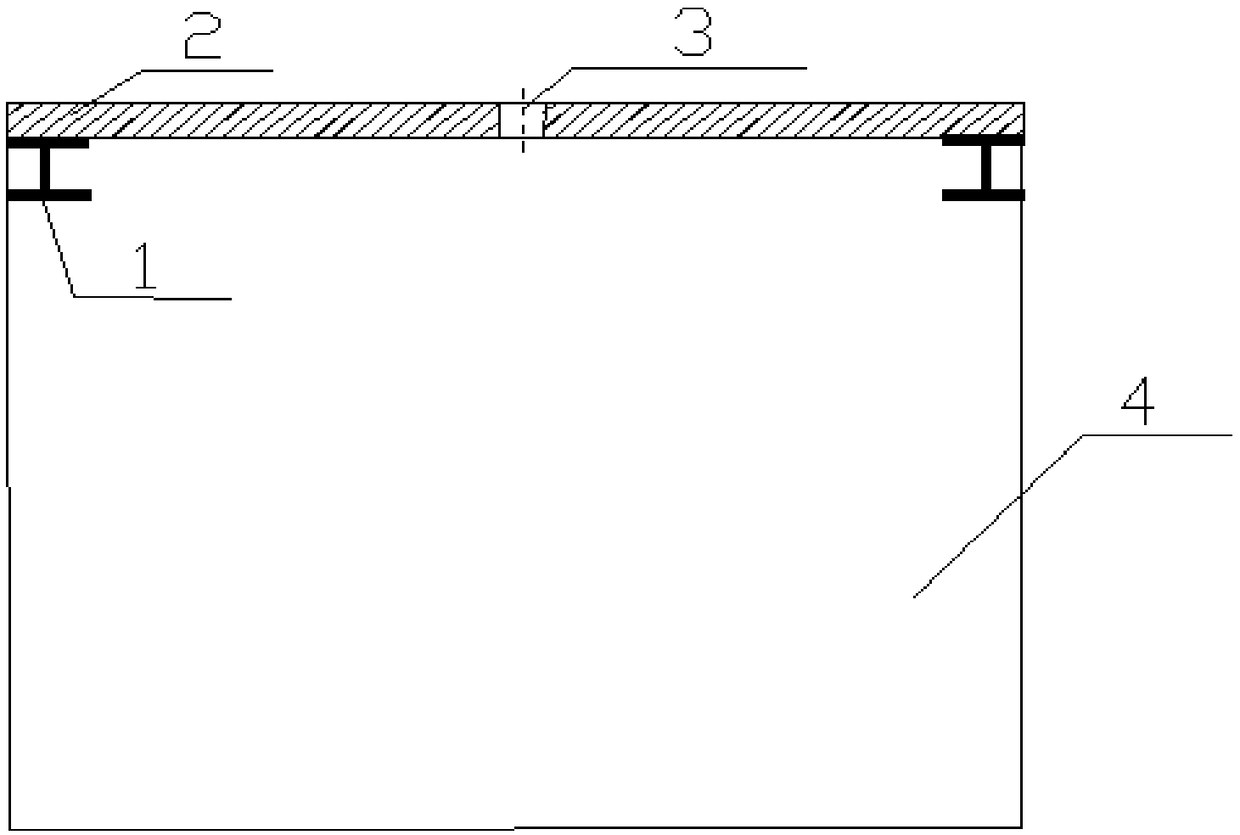

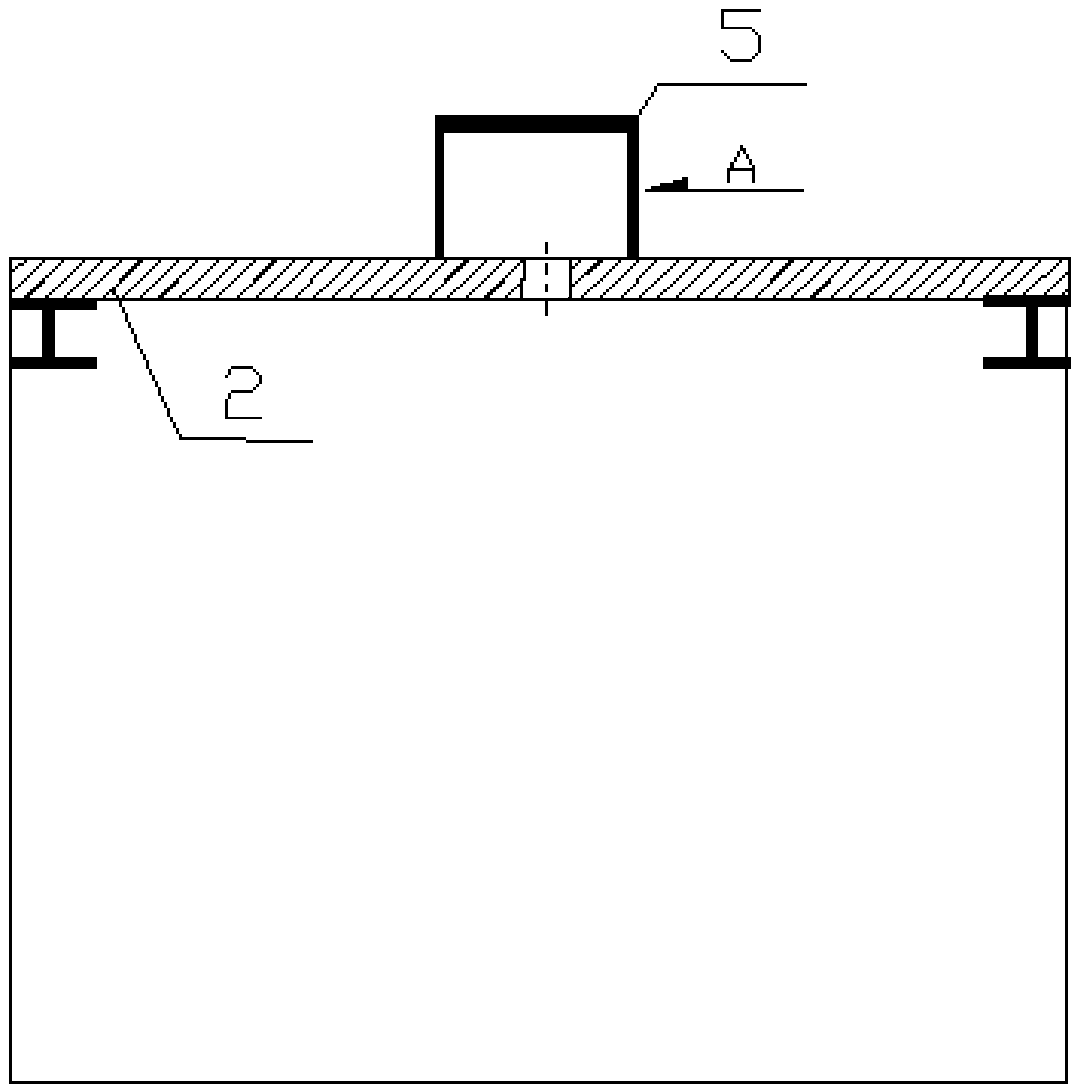

[0016] Figure 1-Figure 5 It is a specific embodiment of the present invention. The specific implementation is as follows:

[0017] The first step is to pre-install the concrete roof 2 in the middle of the steel beam 1 in the basement 4 and drill an 80mm round hole 3 with a water drill;

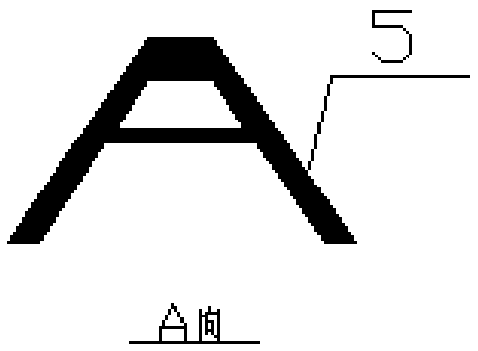

[0018] In the second step, a frock hanger 5 is placed directly above the circular hole 3 of the concrete roof 2, the frock hanger is processed and manufactured on site, and the hoisting guarantees the hoisting strength;

[0019] The third step is to fix the chain-reversing sling 6 on the tooling hanger 5, and vertically pass through the 80mm round hole 3 of the concrete roof, and the sling 7 fixes the steel beam 8 to be installed below the basement 4 (the steel beam is transported from the entrance of the basement by means of transportation) transported to the place directly below the installation location in advance);

[0020] In the fourth step, the tooling hanger 5 is lifted by the hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com