Directional windowing horizontal drilling device and process method

A technology of horizontal drilling and process method, which is applied in directional drilling, drill pipe, drill pipe and other directions, which can solve the problem of easy deviation from the original track and achieve the effect of keeping the track straight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

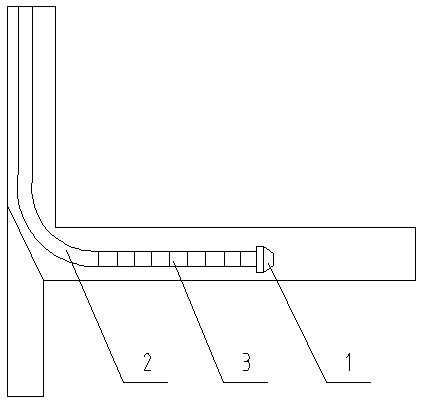

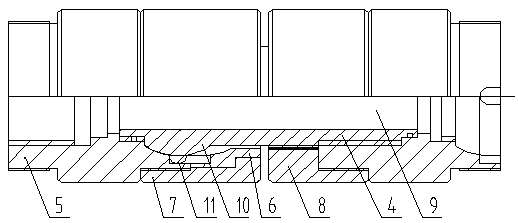

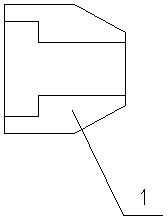

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 Yes figure 1 Enlarged view of the flexible straightening unit in, image 3 It is an enlarged schematic view of the drill bit. As shown in the figure, a directional window-opening horizontal drilling device includes a drill bit 1 and a flexible drill rod 2, and multiple flexible straightening units are connected between the drill bit 1 and the flexible drill rod 2. 3. Each flexible straightening unit 3 includes an inner core 4, a main body 5, a pressure cap 6, a large spare cap 7 and a small spare cap 8, the main body 5 is set on the inner core 4, the inner core 4 is hollow, and a water outlet is formed in the center Channel 9, when drilling, the high-pressure water flow passes through the water passage, and then sprays out from the water outlet of the drill bit. The outer wall of the inner core 4 is provided with a spherical protrusion 10, and the surface of the spherical protrusion 10 ...

Embodiment 2

[0022] A process method for a directional window-opening horizontal drilling device, characterized in that the method comprises the following steps:

[0023] (1) First anchor the oblique device in the casing, and then open a window on the opposite casing of the oblique device;

[0024] (2) Use the skewer to complete a 90° turn in a short distance, and then use the flexible horizontal drilling tool to extend the horizontal direction of the target layer to drill to the limit of the footage, and the drill bit drives multiple flexible straightening units and flexible drill pipes to perform horizontal extension drilling In, the water flows directly to the drill bit through the water passage, and then sprays out through the water outlet on the drill bit. There is an area difference between the water outlet of the drill bit and the inner diameter, which causes the water flow to generate a pressure difference. Under the action of the pressure difference, the main body from the inner co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com