Air cylinder structure and locomotive

A cylinder and gas technology, applied in mechanical equipment, fluid pressure actuation devices, servo motors, etc., can solve problems such as the inability to realize the cylinder buffer function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

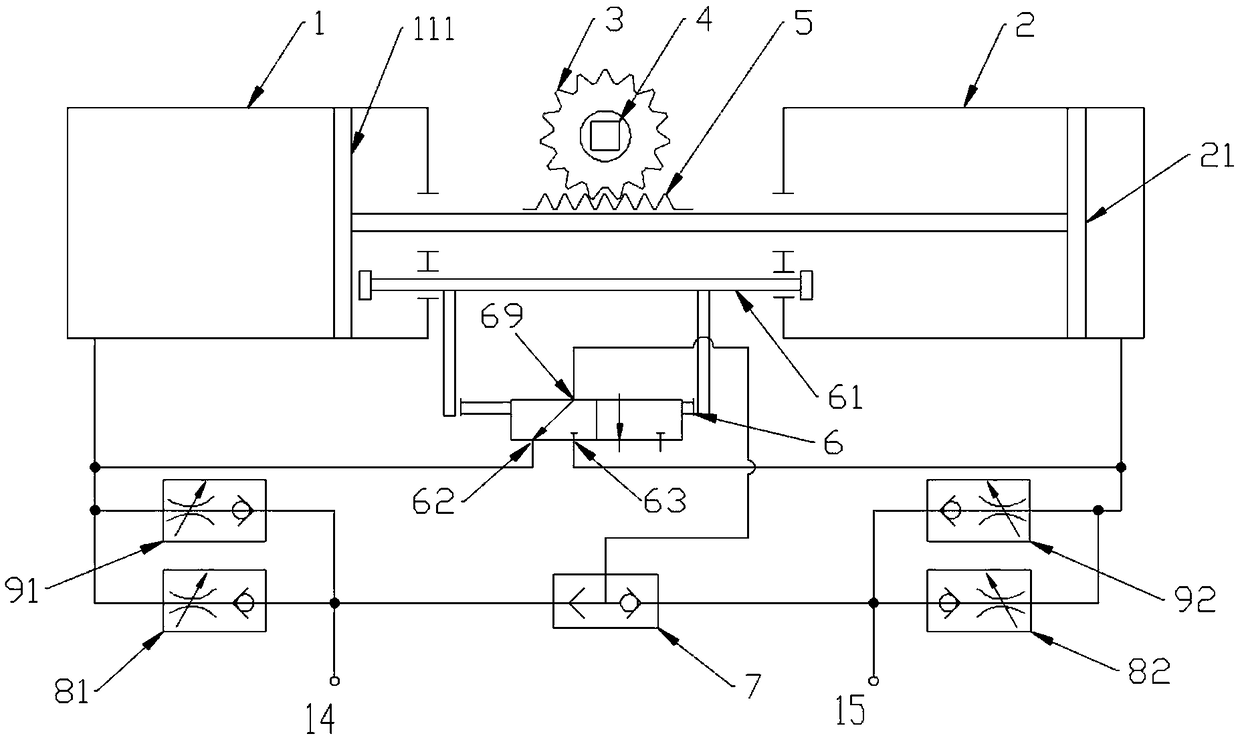

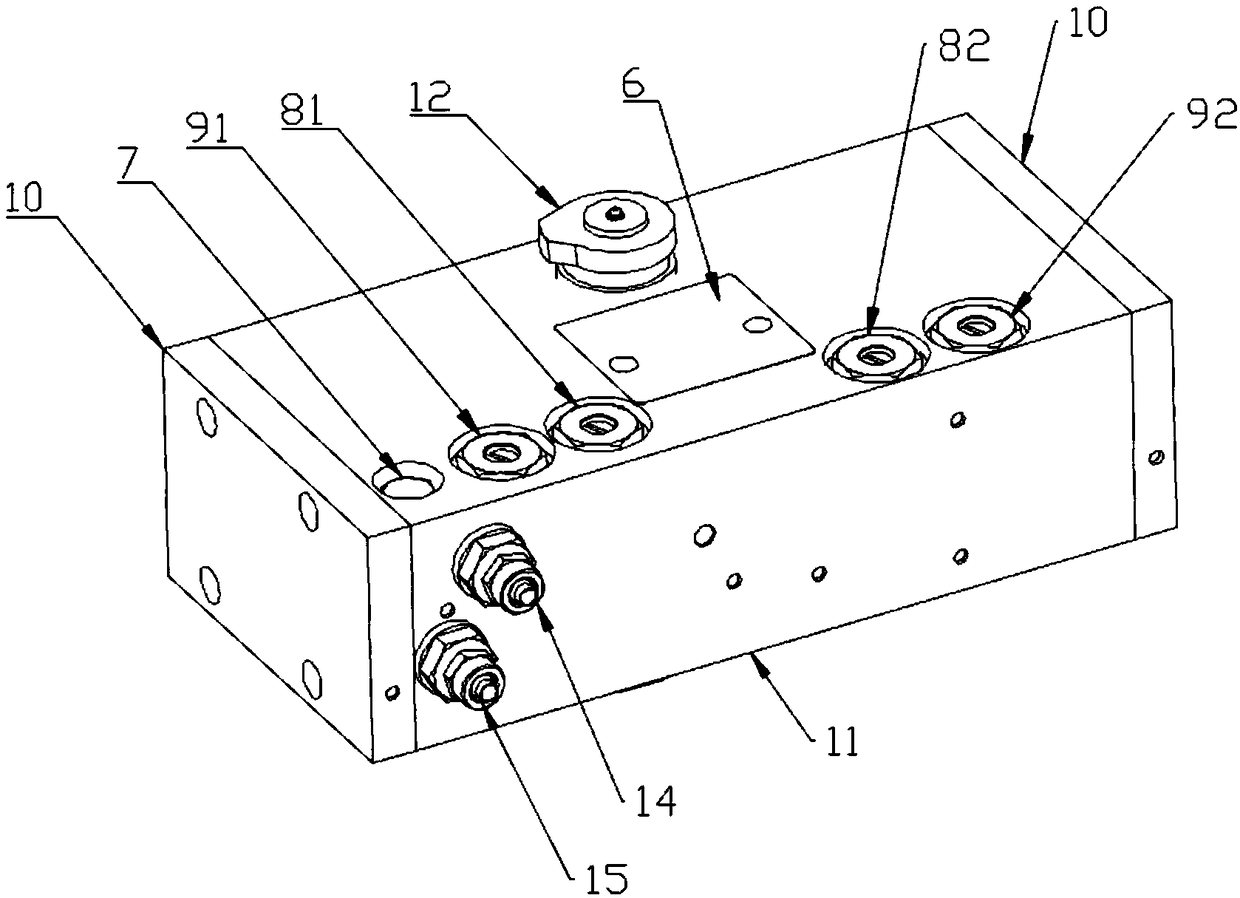

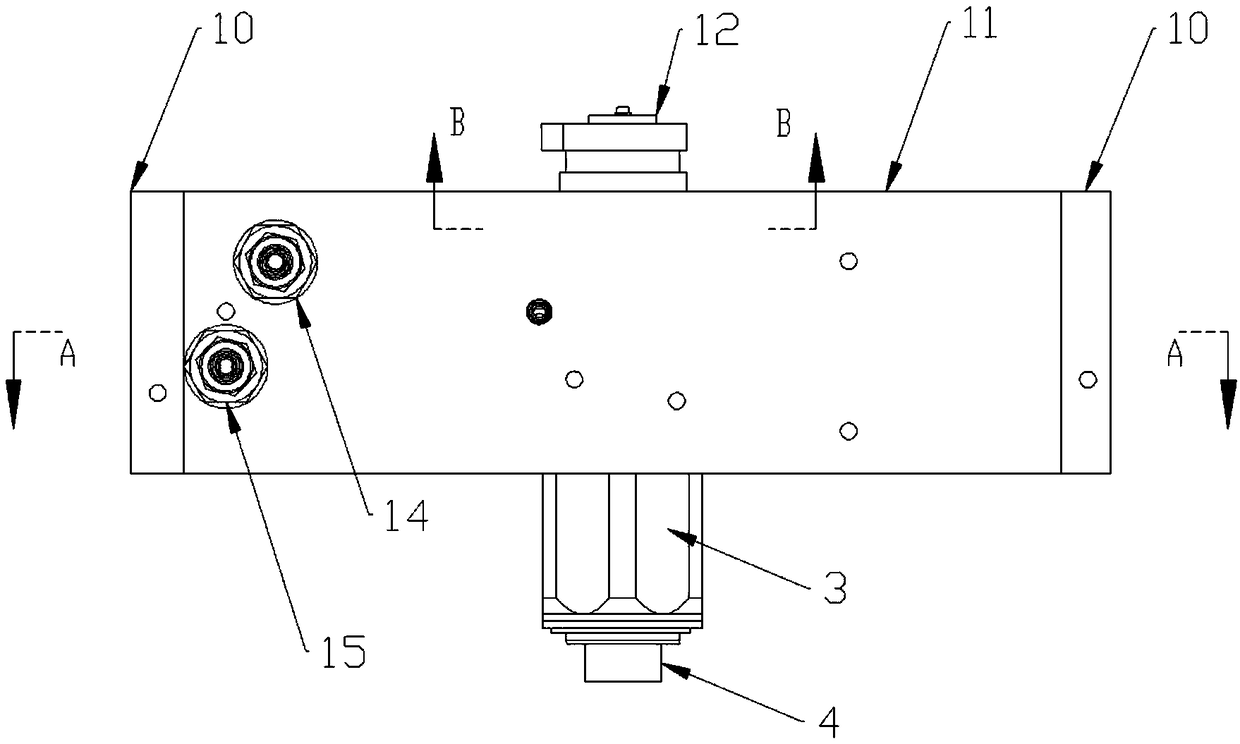

[0043] Such as figure 1 A specific implementation of the shown cylinder structure includes:

[0044] The first cylinder 1 and the second cylinder 2, the first cylinder is provided with a first piston assembly 111, the second cylinder is provided with a second piston assembly 21, the first piston assembly 111 and the second The piston assembly 21 is linked, the first cylinder 1 is provided with a first air inlet 14 and a first exhaust throttle valve 81, and the second cylinder 2 is provided with a second exhaust throttle valve 82;

[0045] The buffer valve 6 is connected with the first air inlet 14, and the first air inlet 14 is connected with a gas source, and the gas flowing in from the first air inlet 14 is divided into two paths, and the first path enters In the first cylinder 1, the second path enters the buffer valve 6;

[0046]The buffer valve 6 has a first position where the gas inside flows into the first cylinder 1 and flows into the second cylinder 2 under the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com