Organic glass protective cover

A plexiglass and protective cover technology, applied in mechanical equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as limited support range, inability to locate protection, and need to be improved, and achieve the effect of improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

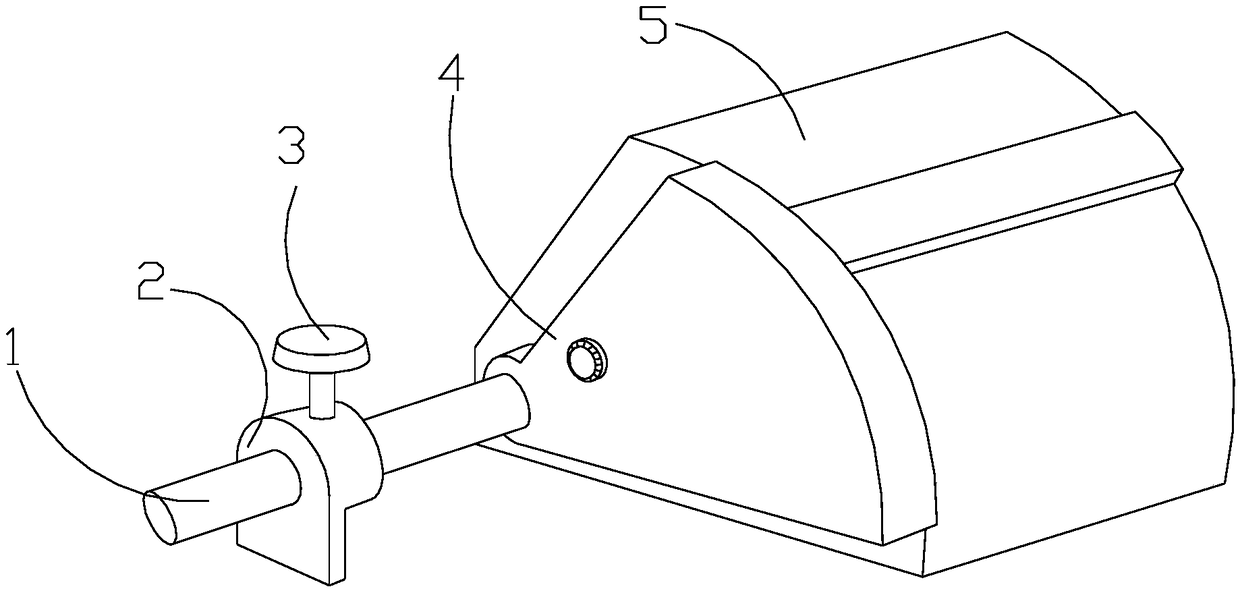

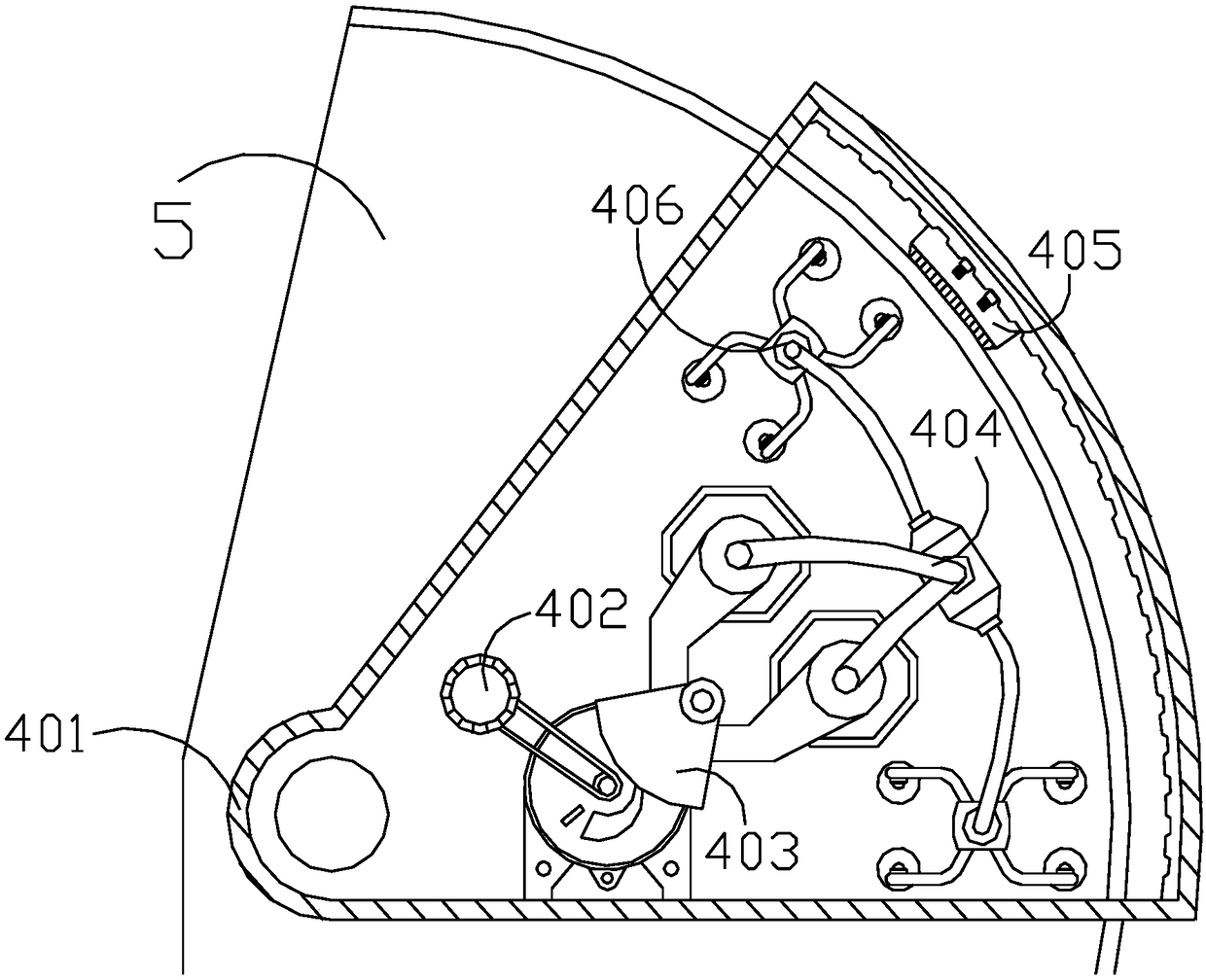

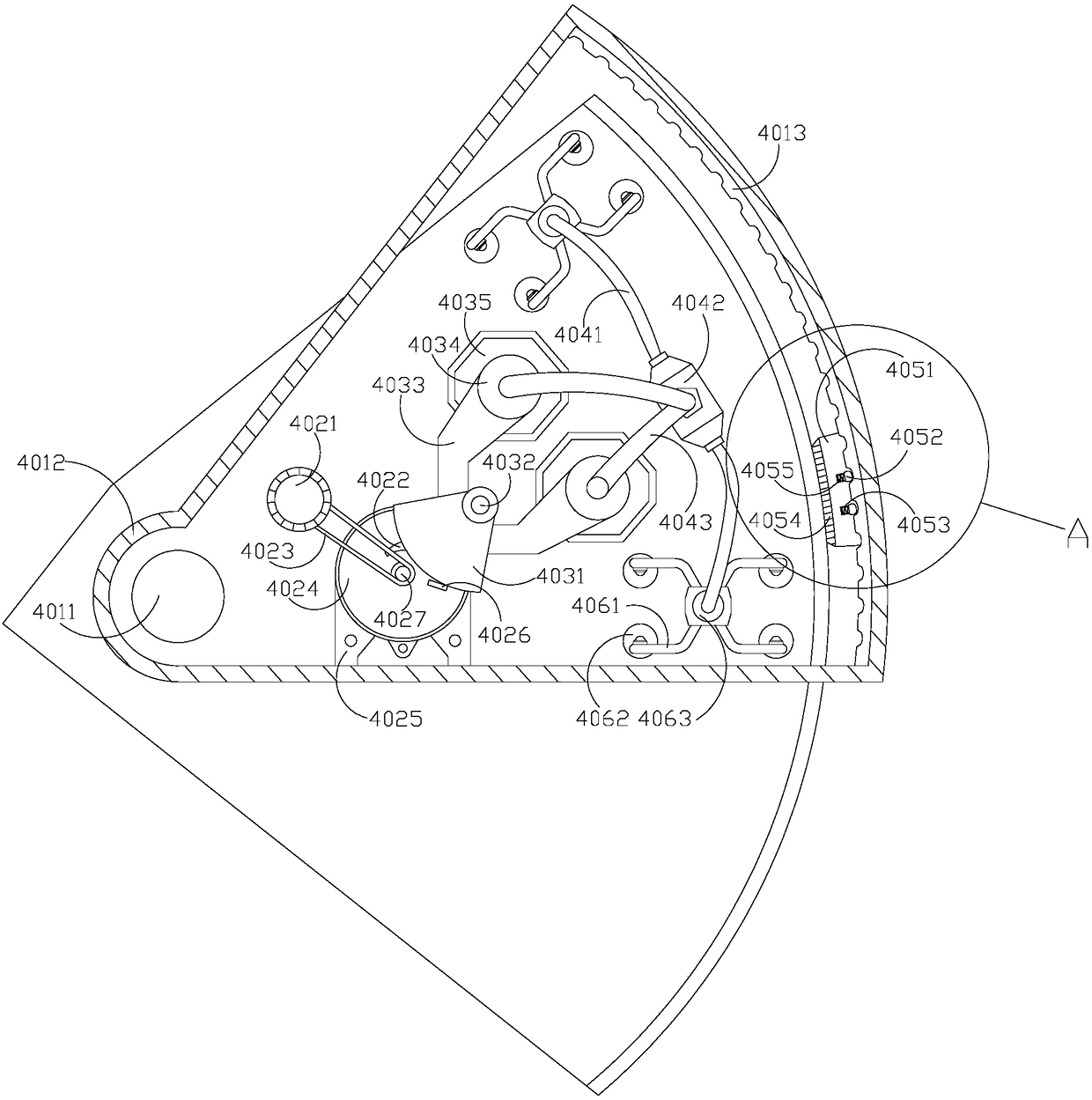

[0025] see Figure 1-Figure 6, the present invention provides a plexiglass protective cover, the structure of which includes a positioning shaft 1, a positioning sleeve 2, an adjustment knob 3, a control device 4, and a protective cover 5. The positioning shaft 1 is a cylindrical structure, and the left end is connected to the positioning sleeve The upper end of the cylinder 2 is fitted together, the top of the positioning sleeve 2 is provided with an adjustment knob 3, the end of the control device 4 is mounted on the right end of the positioning shaft 1 by buckling, and the left end of the protective cover 5 is connected to the right end of the control device 4. Buckling, the control device 4 includes a device main body 401, an adjustment mechanism 402, a negative pressure generating mechanism 403, a negative pressure guiding mechanism 404, a dust removal device 405, and an adsorption mechanism 406. The left end of the device main body 401 is provided with an adjustment mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com