Safety mechanical fault diagnosis detection device

A technology for mechanical faults and detection devices, applied in measuring devices, instruments, etc., can solve the problems of difficult diagnosis of mechanical faults, difficult mechanical faults, and single data collection, and achieve the effect of convenient operation, improved accuracy, and avoid affecting detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

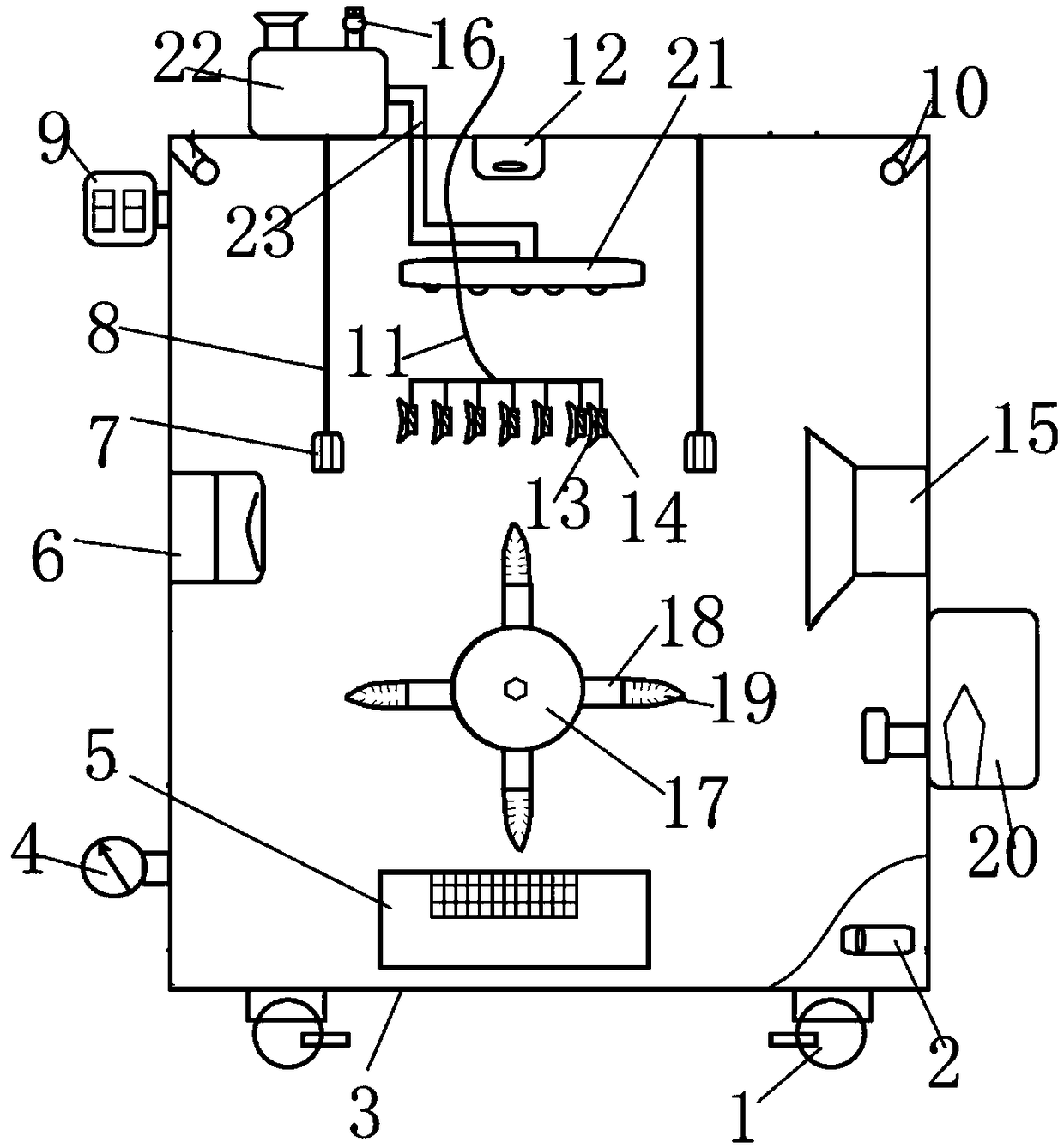

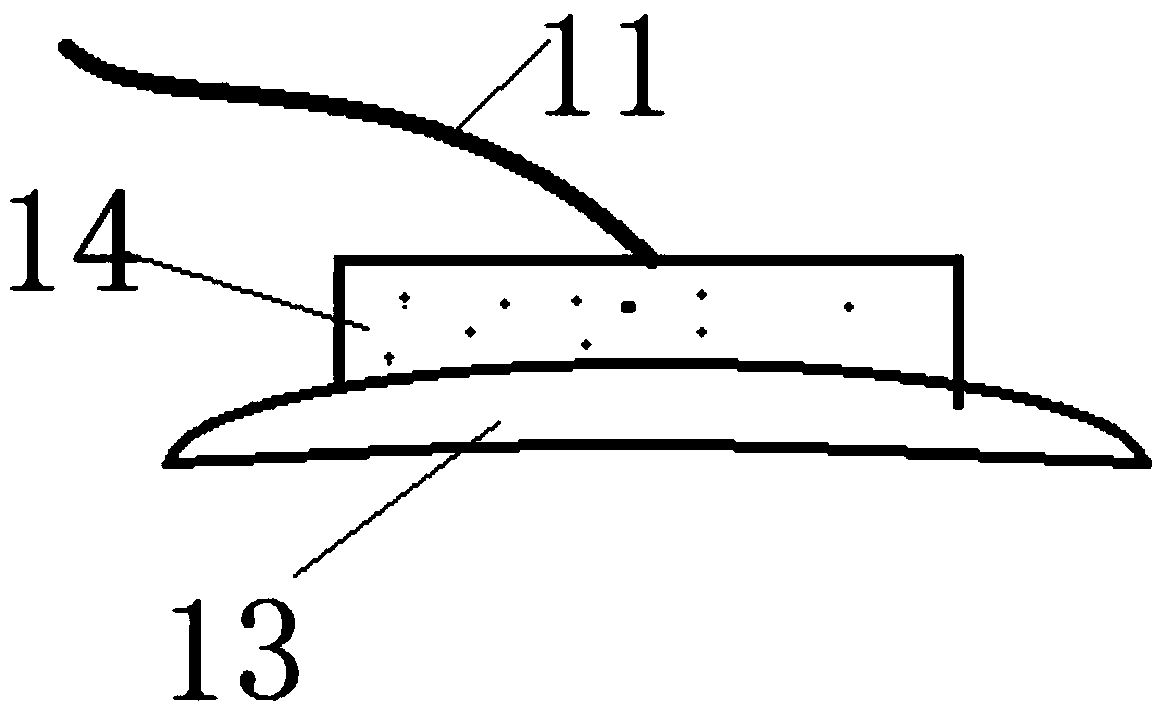

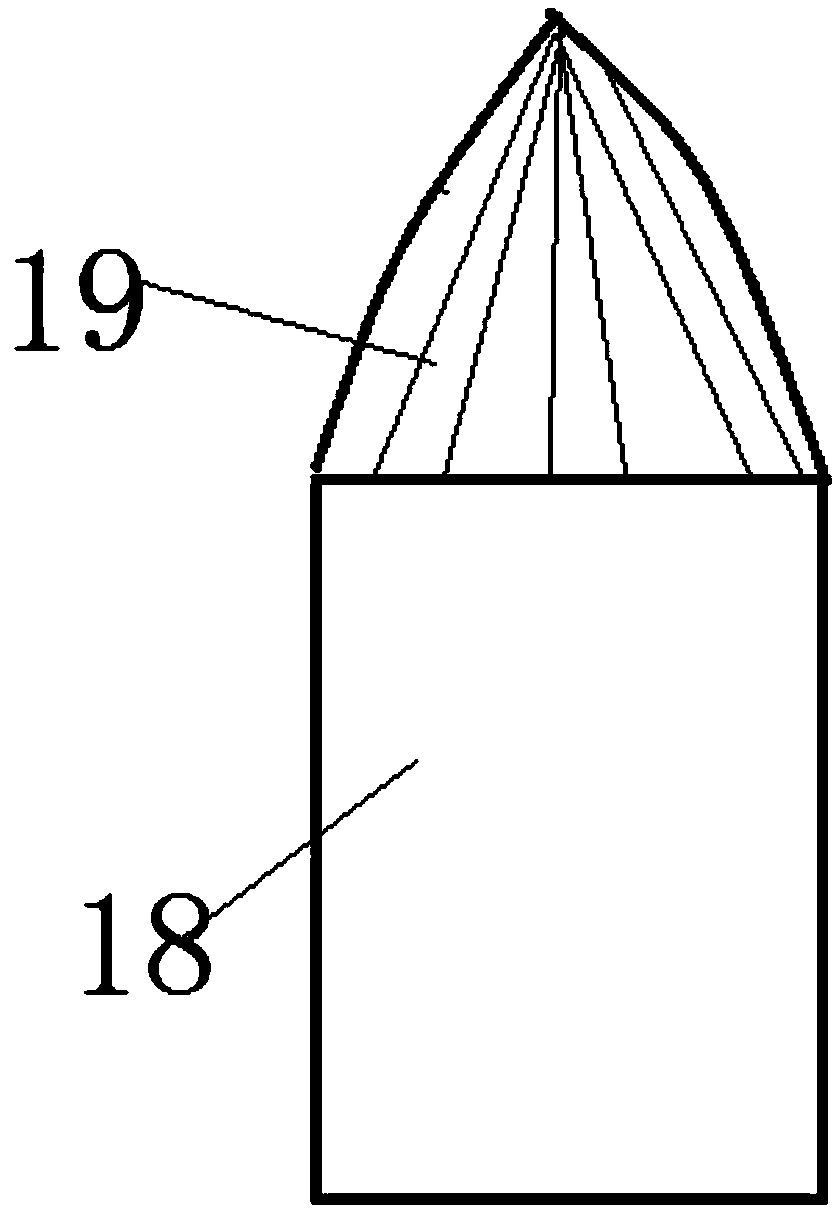

[0018] Example 1: Please refer to Figure 1-3 , a safety mechanical fault diagnosis and detection device, including a guide wheel 1, a box body 3, a thermometer 4, a heater 5, an infrared detector 6, a fixing clip 7, a timer 9, an LED light 10, a data transmission line 11, a camera 12, Temperature sensor 14 and ultrasonic detector 15, described casing 3 is provided with sealed box door, opens the sealed box door and puts in the machinery to be detected, and box body 3 inner wall is provided with heater 5, and box body 3 side walls are provided with Thermometer 4, the thermometer 4 controls and records the heating temperature of the heater 5, the inner wall of the box body 3 is also provided with an infrared detector 6 and an ultrasonic detector 15, the top of the box body 3 is provided with an elastic rope 8, and the elastic rope 8 is provided with a fixing clip 7. The object to be tested is fixed and clamped by the fixing clip 7. The data transmission line 11 is provided in t...

Embodiment 2

[0021] Embodiment 2: On the basis of Embodiment 1, a guide wheel 1 is provided on the bottom surface of the box body 3, and a hand brake is provided on the guide wheel 1. The guide wheel 1 is convenient for the device to move, saving time and effort, and a level is provided on the side wall of the bottom end of the box body 3 2. The spirit level 2 ensures the level of the device when it is placed to avoid affecting the detection. The box body 3 is provided with a timer 9, which controls and records the detection time. The inner wall of the top of the box body 3 is provided with an LED light 10 and a camera 12. The camera 12 and The remote display device is connected, and the detection situation in the box body 3 can be clearly seen through the camera 12, which is convenient for timely adjustment, and the LED lamp 10 provides illumination for convenient detection.

[0022] The working principle of the present invention is: the guide wheel of the present invention facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com