Sampling method for plastic concrete cut-off wall

A technology of plastic concrete and anti-seepage wall, applied in the direction of sampling device, etc., can solve the problem of not representing the quality of the wall, and achieve the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

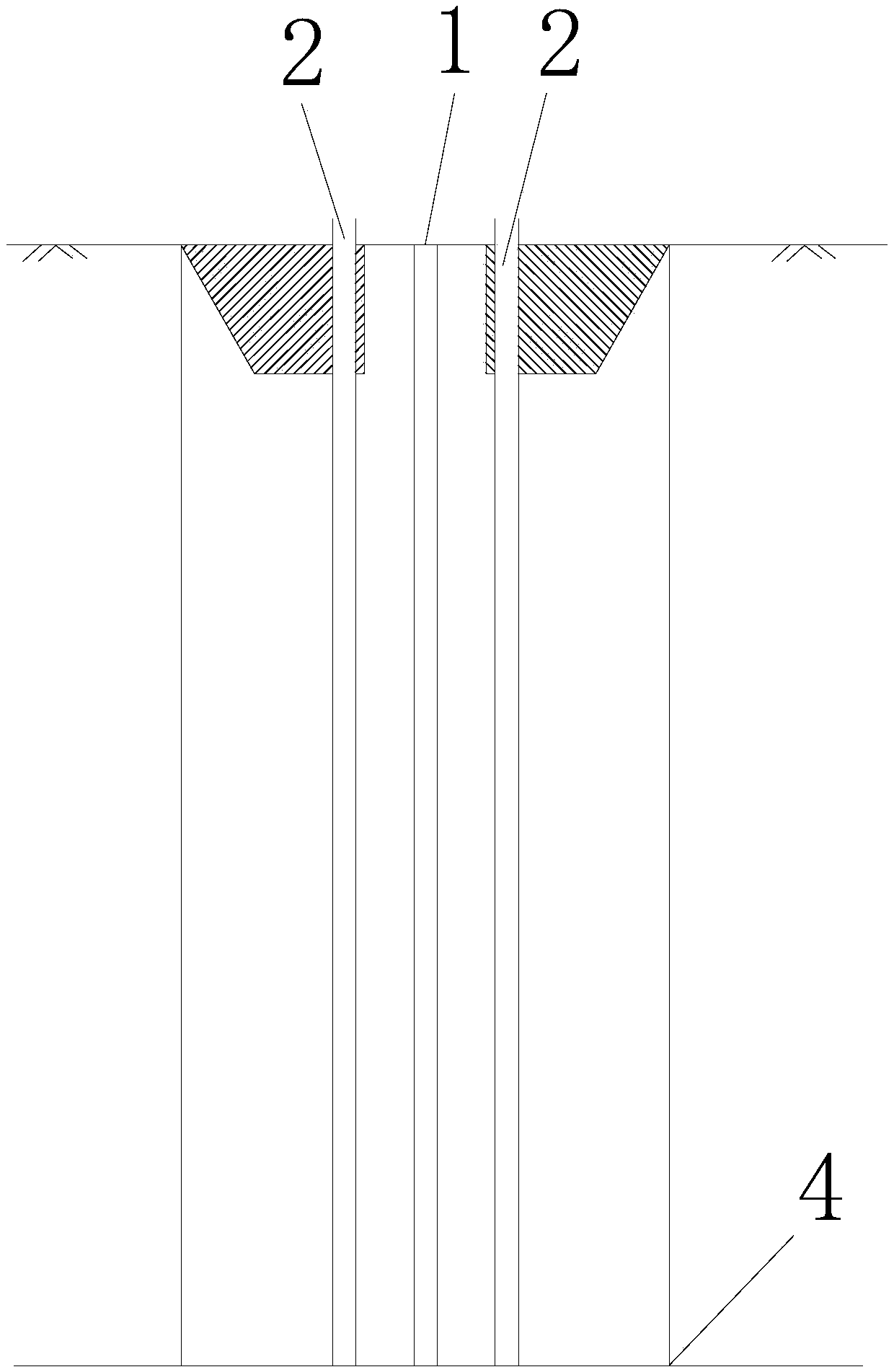

[0025] A method for sampling plastic concrete cut-off walls. Freezing the plastic concrete cut-off wall sampling position 1 can freeze the plastic concrete cut-off walls tightly and greatly improve the strength, preventing cracking or collapse caused by sampling, and at the same time It is convenient to take core samples that meet the requirements.

[0026] Holes were sampled when frozen to set conditions.

[0027] Preferably, corresponding to the sampling position 1, a freezing tube 2 is provided on the outer side of the plastic concrete cut-off wall, and when the temperature of the sampling position 1 is below -20°C, the core is drilled.

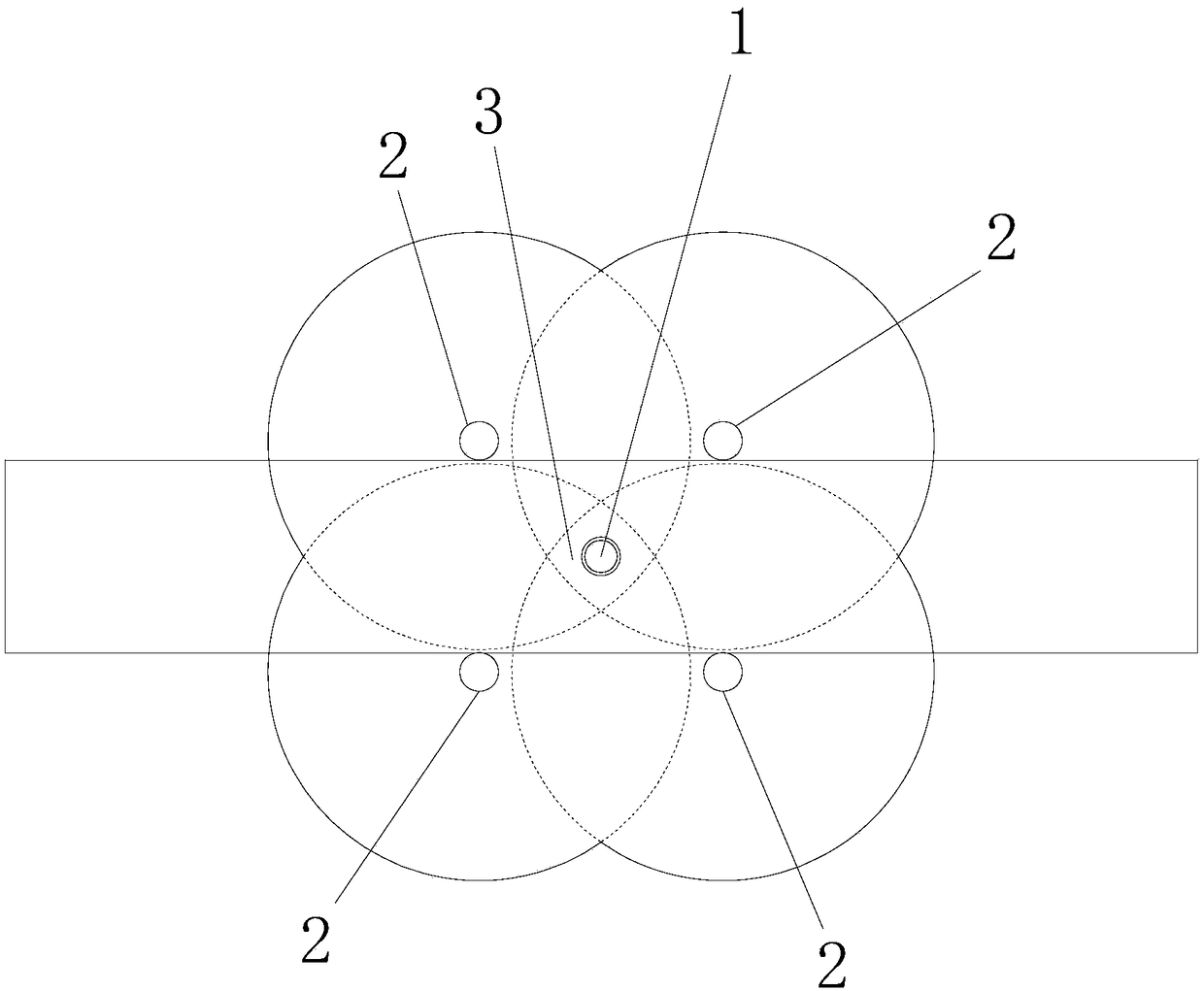

[0028] Preferably, there are multiple freezing pipes 2, and the multiple freezing pipes 2 are respectively surrounded on the outsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com