Simulation optimization method of compressor piping vibration of constant frequency air conditioner

An optimization method and compressor technology, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems such as ambiguity in the optimization direction of the compressor piping system, and achieve the effect of shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

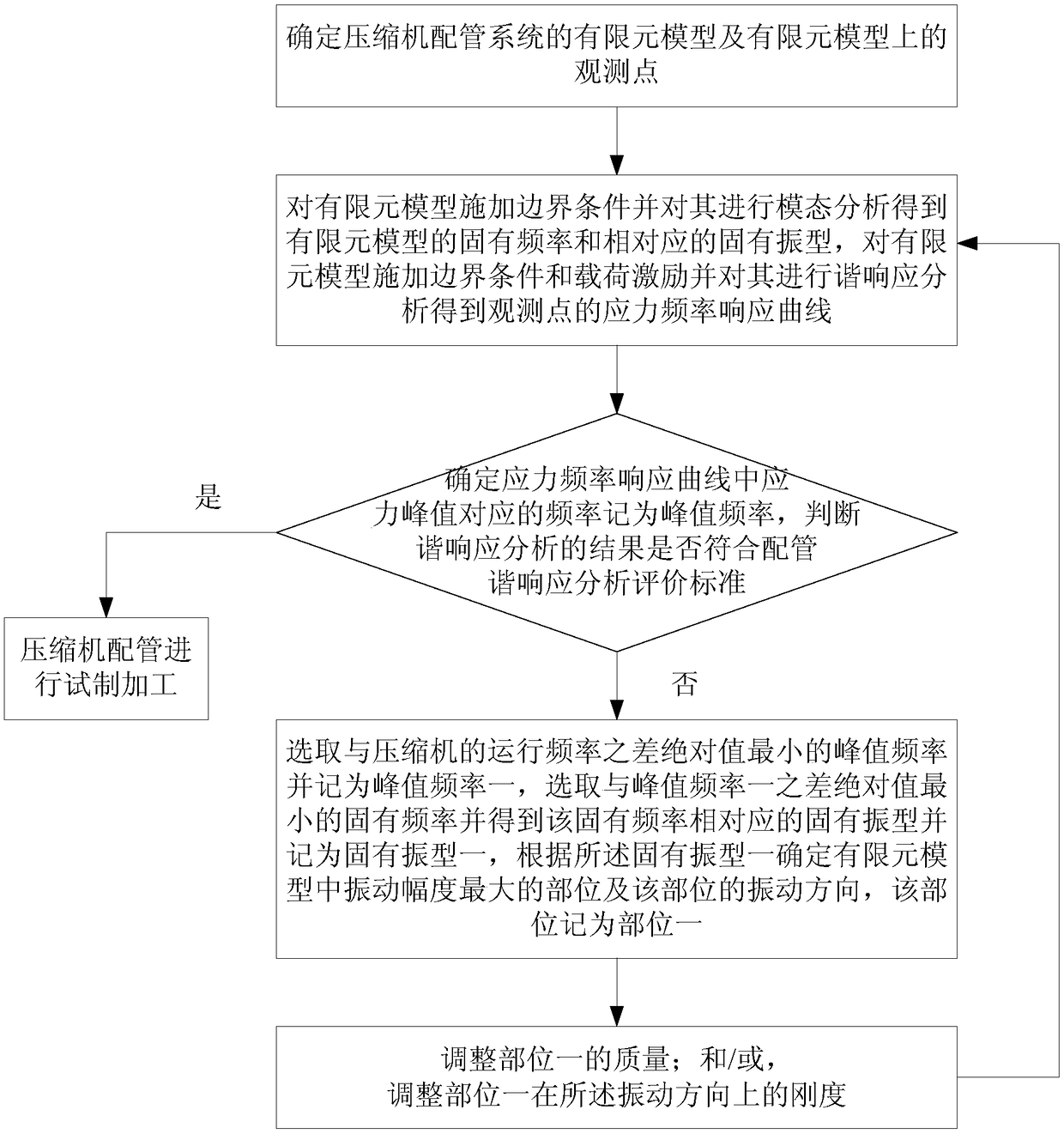

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

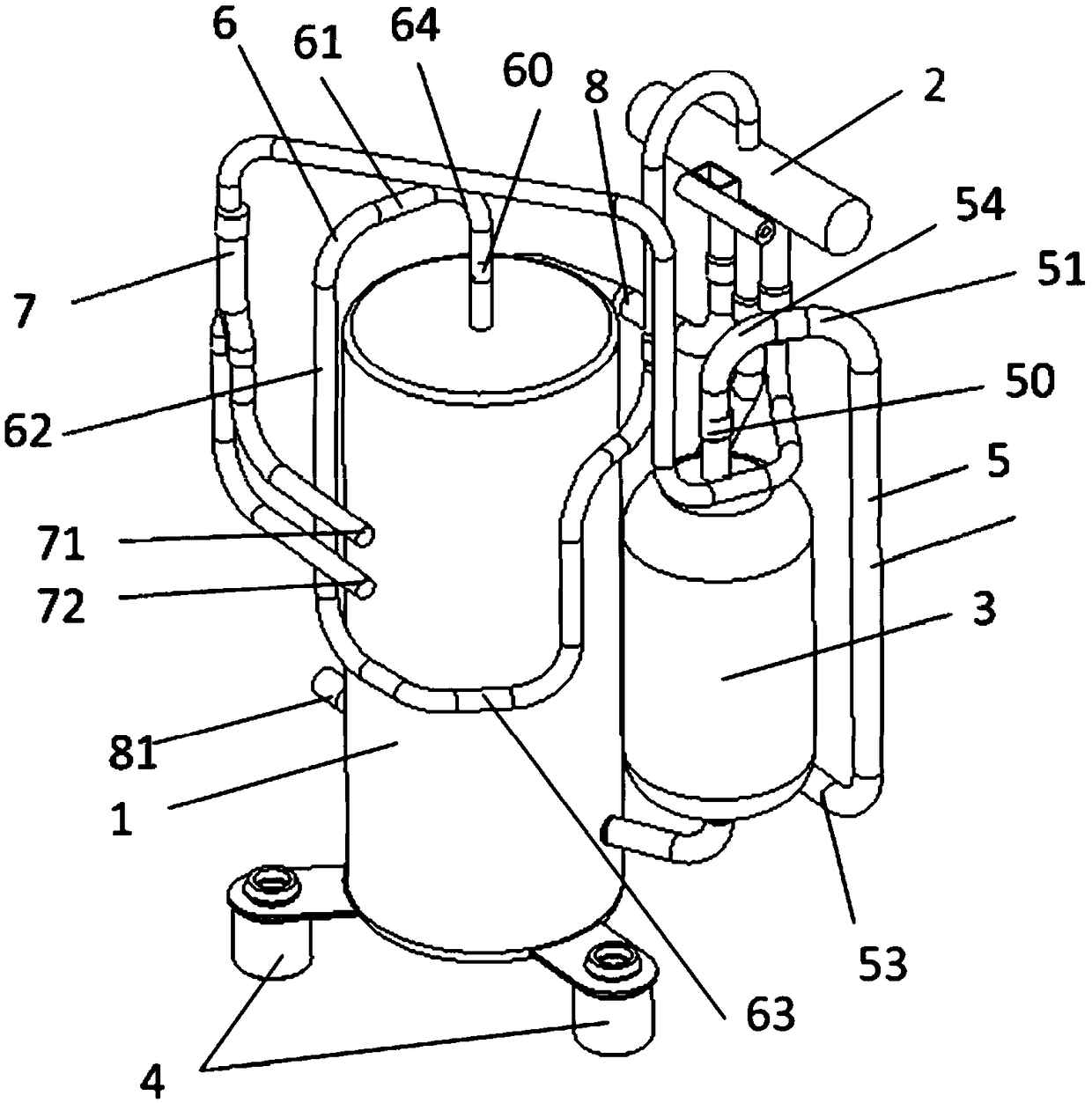

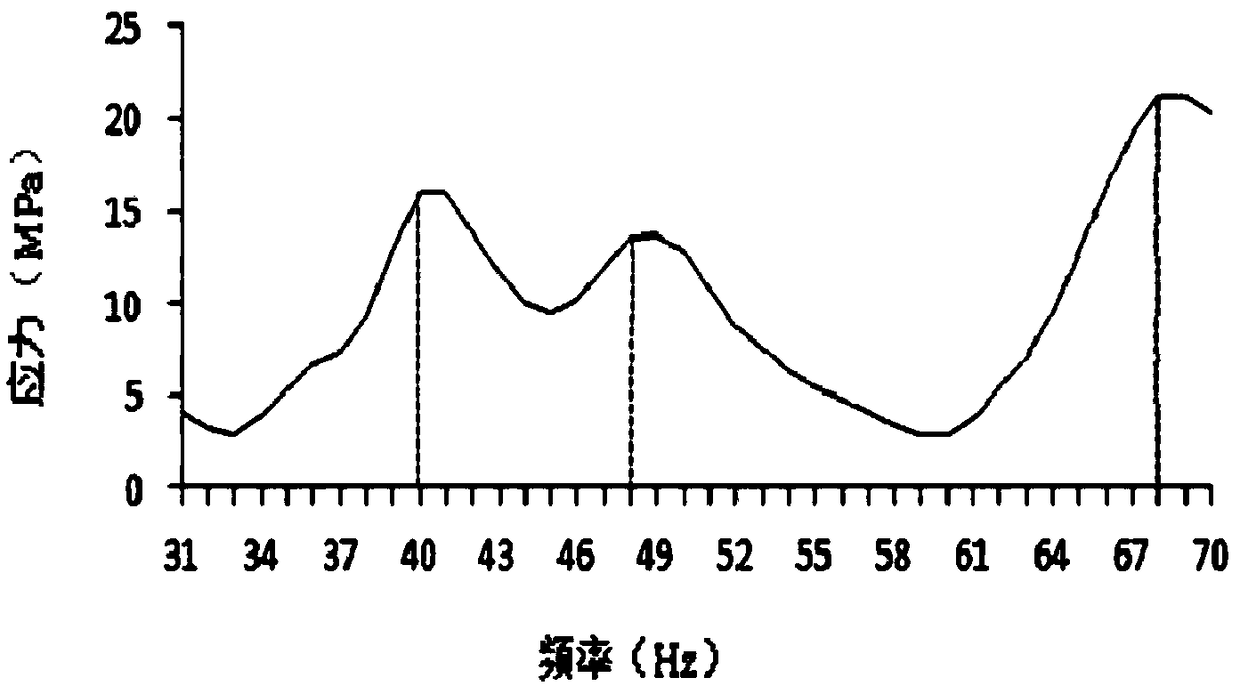

[0058] Such as figure 2 As shown, the finite element model may include a compressor cylinder 1, a four-way valve 2, a liquid storage tank 3 connected to the compressor cylinder 1, a rubber foot 4 for fixing the compressor cylinder 1, and a suction pipe connected to the liquid storage tank 3. The air port and the suction pipe 5 of the four-way valve 2, the exhaust pipe 6 connecting the exhaust port of the compressor cylinder 1 and the four-way valve 2, and the connecting pipe 7 for connecting the four-way valve 2 and the heat exchanger And the connecting pipe two 8 for connecting the four-way valve 2 and the shut-off valve, the connecting pipe one 7 includes the boundary nozzle one 71 and the boundary nozzle two 72, and the connecting pipe two 8 includes the boundary nozzle three 81.

[0059] The suction pipe 5 includes a first extension portion 50 of the suction pipe extending outward from the suction port of the liquid storage tank 3, a first bent portion 51 of the suction p...

Embodiment 2

[0071] The difference between this embodiment and the first embodiment is that there is only one stress peak value on the stress frequency response curves of the observation point 1 and the observation point 2 respectively.

[0072] Such as Figure 7 As shown, the finite element model may include a compressor cylinder 1, a four-way valve 2, a liquid storage tank 3 connected to the compressor cylinder 1, a rubber foot 4 for fixing the compressor cylinder 1, and a suction pipe connected to the liquid storage tank 3. The air port and the suction pipe 5 of the four-way valve 2, the exhaust pipe 6 connecting the exhaust port of the compressor cylinder 1 and the four-way valve 2, and the connecting pipe 7 for connecting the four-way valve 2 and the heat exchanger And the connecting pipe two 8 for connecting the four-way valve 2 and the shut-off valve, the connecting pipe one 7 includes the boundary nozzle one 71 and the boundary nozzle two 72, and the connecting pipe two 8 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com