Delimbing tool for live working robot

A live working and robot technology, applied in the field of machinery, achieves the effect of improving work efficiency, simple and novel structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

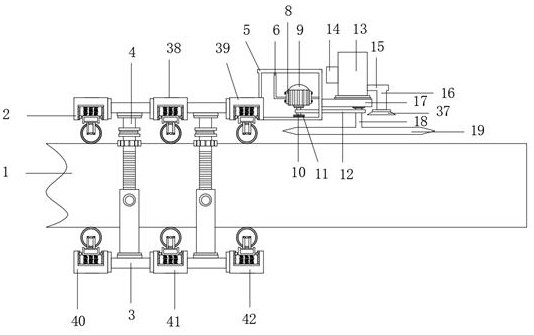

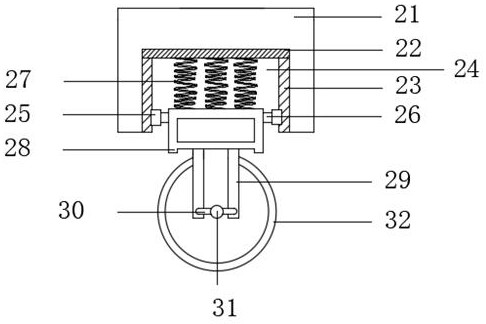

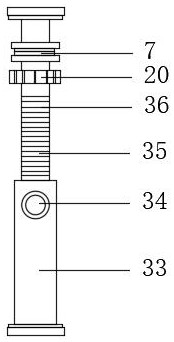

[0018] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: the live working robot debranching tool includes a trunk 1, a No. 1 moving mechanism 2 and a connecting mechanism 4, and the No. 1 moving mechanism 2 and No. 2 moving mechanism are evenly arranged on both sides of the trunk 1. Mobile mechanism 38, No. 3 mobile mechanism 39, No. 4 mobile mechanism 40, No. 5 mobile mechanism 41 and No. 6 mobile mechanism 42, described No. 1 mobile mechanism 2 is provided with connection base 21 away from the side of trunk 1, described A spring chamber 24 is arranged in the connection base 21, and a spring base 22 is arranged at the top of the spring chamber 24 and in the connection base 21. The two sides of the spring chamber 24 are provided with a connection chute 23, and on the connection chute 23 A connecting slider 25 is connected, and the connecting slider 25 is connected with a No. 2 connecting rod 26 on a side away from the connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com