Food processing bidirectional multifunctional knife assembly and processing process thereof

A technology for food processing and processing technology, which is applied in the field of food processing two-way multi-function knife components and its processing technology, can solve the problems that equipment cannot be used universally, soybeans cannot be squeezed into soybean milk, and medicinal materials cannot be grinded, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

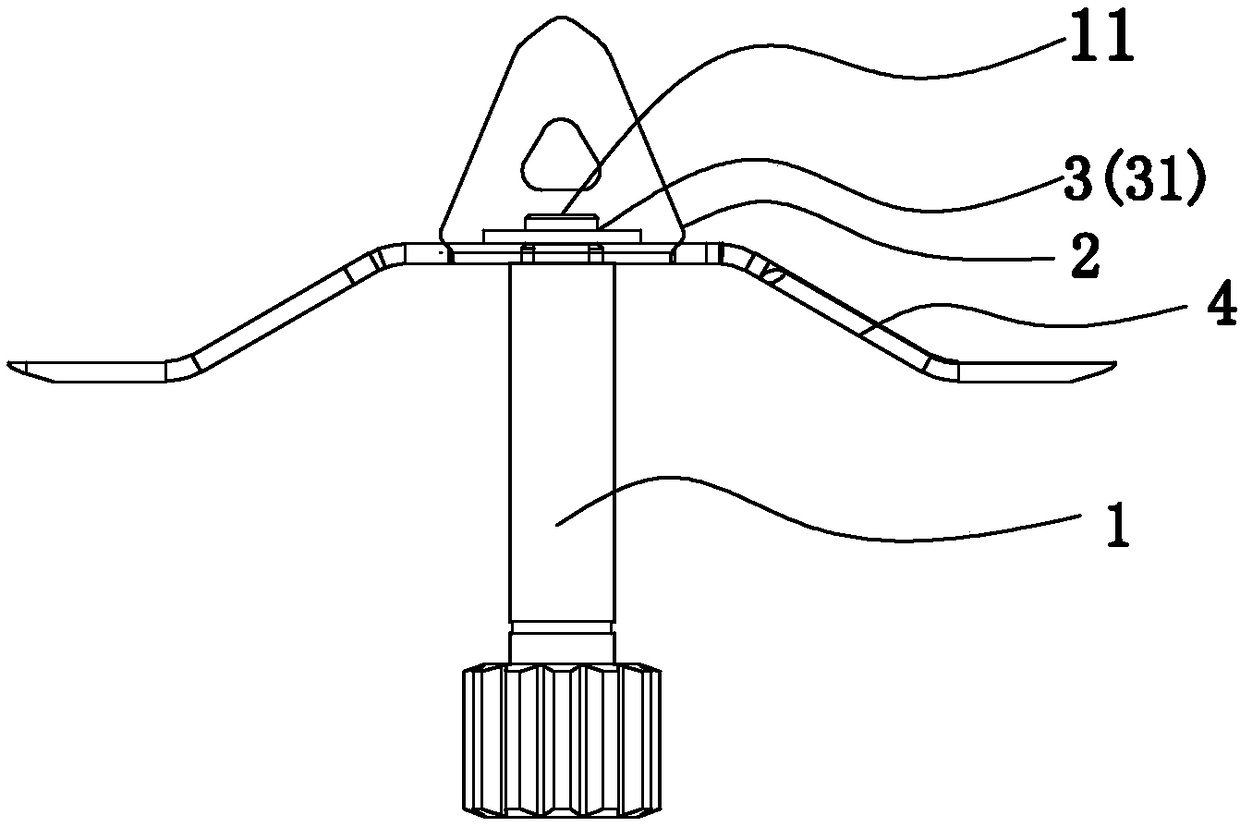

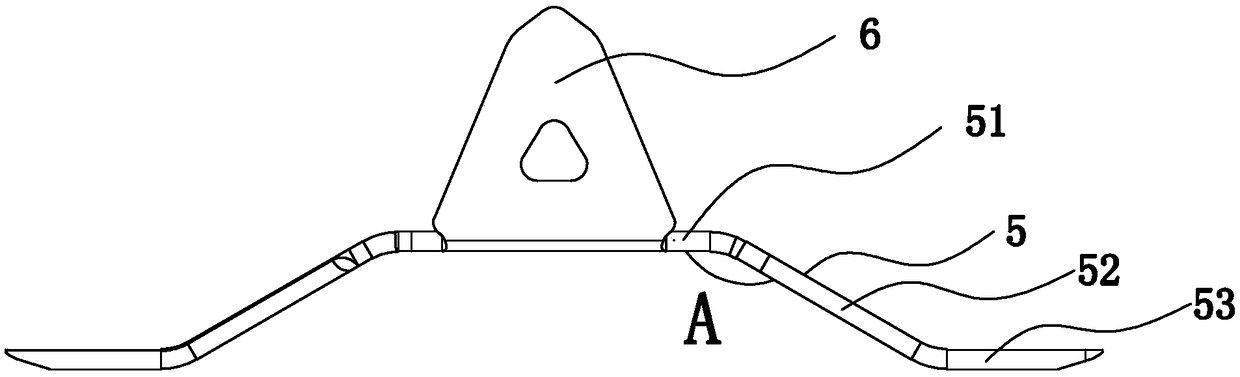

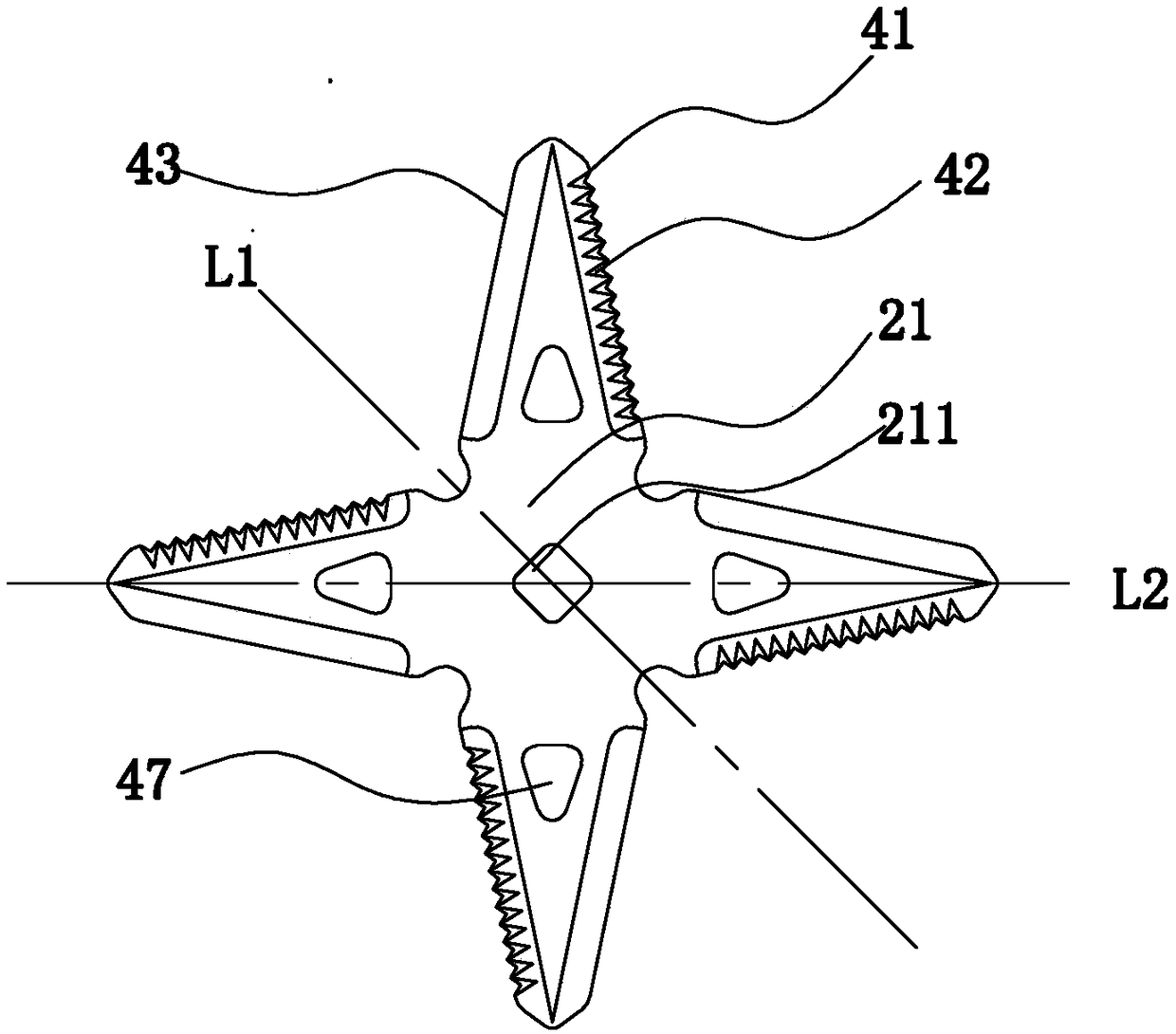

[0057] Refer to attached Figure 1-5 As shown, a food processing two-way multifunctional knife assembly includes a knife shaft 1, a knife 2 and a spacer 3, the knife 2 includes at least one blade 21, and the number of blades 21 can be multiple, and the blade 21 is provided with at least two The blades 4 that are distributed in a circular array, the number of blades 4 can be multiple, can be two, three, four, six, eight or the like, here only one blade 21 with four blades 4 For example, the blade 4 includes two lower blades 5 and two middle blades 6, the connection line of the two lower blades 5 and the connection line of the two middle blades 6 are vertically arranged, the lower blade 5 is bent downward, and the middle blade 6 is upward bending, and further in order to improve the overall cutting effect, an upper blade can also be added, and the upper blade is also upwardly bent, but the angle of its bending is greater than that of the middle blade 6. Further, the number of b...

Embodiment 2

[0067] Refer to attached Figure 6-7 As shown, a processing technology of a bidirectional multifunctional knife assembly for food processing includes a bidirectional multifunctional knife assembly for food processing. The specific structure of the bidirectional multifunctional knife assembly for food processing has been described in detail in Embodiment 1, so it will not be repeated here. More details, the processing technology is:

[0068] Step A: cutting the raw material;

[0069] Step B: stamping;

[0070] Step C: two-way sharpening the blade of the stamped material;

[0071] Step D: Carry out tooth opening;

[0072] Step E: Grinding and deburring;

[0073] Step F: ultrasonic cleaning;

[0074] Step G: bending forming;

[0075] Step H: Cleaning with cleaning solution;

[0076] Step I: electrolytic polishing;

[0077] Step J: wash with clean water once;

[0078] Step K: passivation treatment;

[0079] Step L: washing with clean water for the second time;

[0080] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap