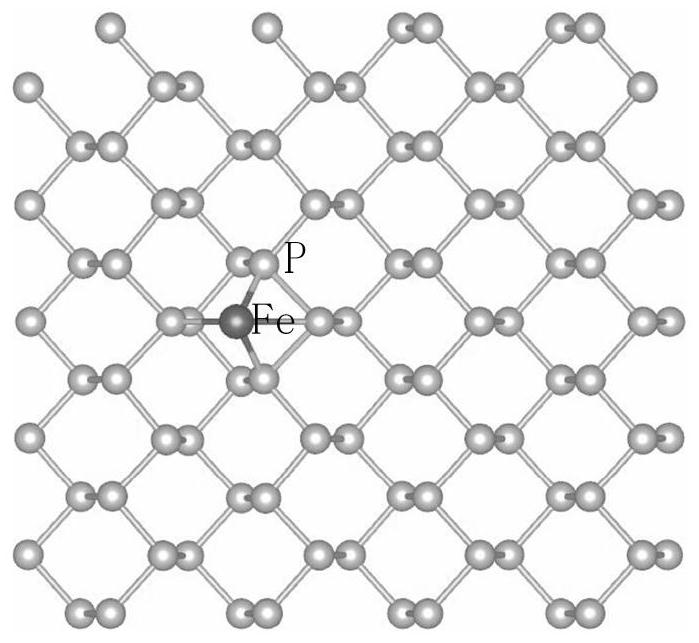

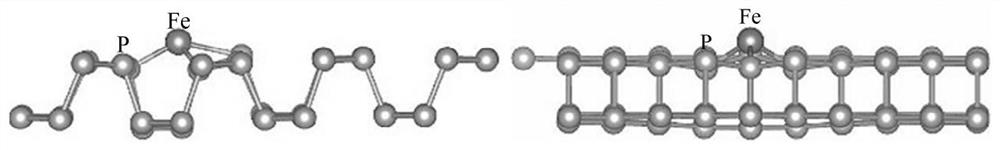

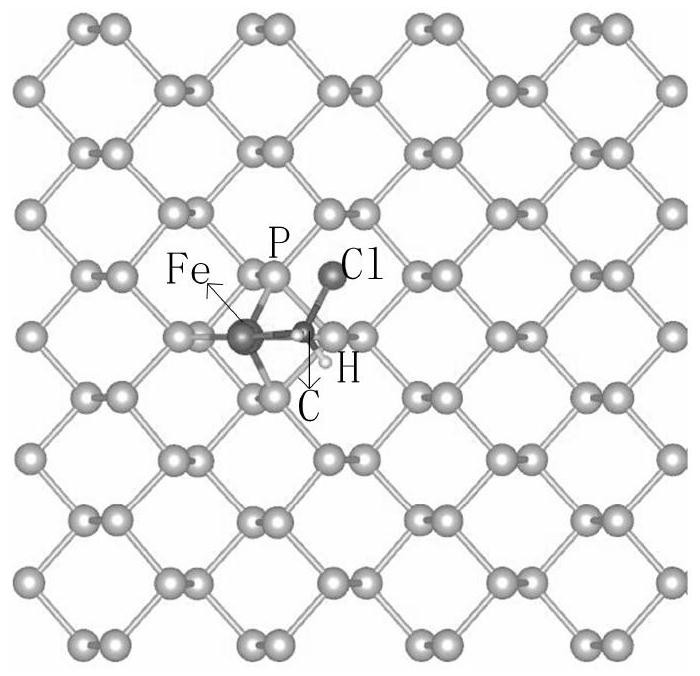

Metal Fe-modified black phosphorene and its preparation method and application

A technology of black phosphorene and metal, which is applied in the field of metal Fe-modified black phosphorene and its preparation, can solve the problems that limit the application of black phosphorene, and achieve the effects of increased efficiency, miniaturized volume, and reduced sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of metal Fe modified black phosphorene catalyst is as follows:

[0040] A) take by weighing red phosphorus, purify in deionized water for 15 minutes, after taking out, in vacuum (vacuum degree is 10 -2 -10 -3 Pa) drying in oven for 20 minutes, put into desiccator after processing for ready use;

[0041] B) Put the above dry red phosphorus into a tube furnace, put a silicon substrate in the tube furnace, evacuate the tube furnace and raise the temperature to 630°C, keep it for 30 minutes, then close the tube furnace and put it at room temperature Cool down to obtain a Si substrate covered with a red phosphorus film;

[0042] C) Transfer the obtained Si substrate coated with red phosphorus film to a conical-bottom glass centrifuge tube containing Sn / SnI (red phosphorus film: Sn:SnI=1:4:2), and then put the centrifuge tube into the pressure In the container reactor, and fill the reactor with argon to reach 26atm, fix the reactor in a tube furnace ...

Embodiment 2

[0056] A preparation method for metal Fe modified black phosphorene catalyst, comprising the following steps:

[0057] A) take by weighing red phosphorus, purify in deionized water for 17 minutes, after taking out, in vacuum (vacuum degree is 10 -2 -10 -3 Pa) drying in oven for 23 minutes, put into desiccator after processing for ready use;

[0058] B) Put the above-mentioned dry red phosphorus into a tube furnace, and put a silicon substrate in the tube furnace, pump the tube furnace to vacuum and heat up to 600°C, keep it for 35 minutes, then close the tube furnace and put it at room temperature Cool down to obtain a Si substrate covered with a red phosphorus film;

[0059] C) Transfer the obtained Si substrate coated with red phosphorus film to a conical-bottom glass centrifuge tube containing Sn / SnI (red phosphorus film: Sn:SnI=1:4:2), and then put the centrifuge tube into the pressure In the container reactor, and fill the reactor with argon to reach 26.5atm, fix the r...

Embodiment 3

[0063] A preparation method for metal Fe modified black phosphorene catalyst, comprising the following steps:

[0064] A) take by weighing red phosphorus, purify in deionized water for 19 minutes, after taking out, in vacuum (vacuum degree is 10 -2 -10 -3 Pa) drying in oven for 27 minutes, put into desiccator after processing for ready use;

[0065] B) Put the above-mentioned dry red phosphorus into a tube furnace, and put a silicon substrate in the tube furnace, pump the tube furnace to vacuum and heat up to 650°C, keep it for 32 minutes, then close the tube furnace and put it at room temperature Cool down to obtain a Si substrate covered with a red phosphorus film;

[0066] C) Transfer the obtained Si substrate coated with red phosphorus film to a conical-bottom glass centrifuge tube containing Sn / SnI (red phosphorus film: Sn:SnI=1:4:2), and then put the centrifuge tube into the pressure In the container reactor, and fill the reactor with argon to reach 27.8atm, fix the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com