High-efficiency automatic sand making machine

A sand making machine and high-efficiency technology, applied in grain processing and other directions, can solve the problems of inability to independently crush sand and poor automation, and achieve the effect of high automation and high crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

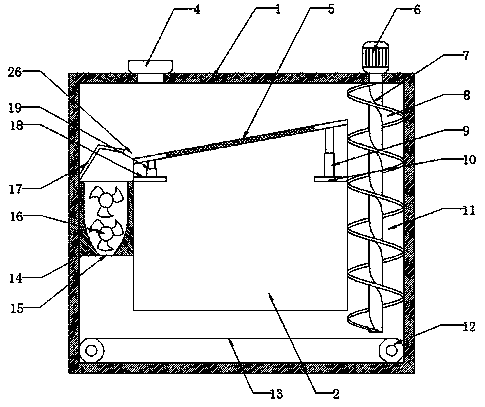

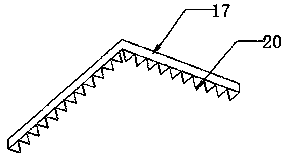

[0028] see Figure 1-4 , this embodiment provides a high-efficiency automatic sand making machine, including a crushing box 1 and a fine sand storage box 2; the fine sand storage box 2 is arranged in the middle of the crushing box 1, and the right side of the fine sand storage box 2 is connected A lifting channel 11 is arranged between the crushing boxes 1; a lifting shaft 7 is arranged in the lifting channel 11; a spiral lifting plate 8 is fixedly connected to the lifting shaft 7, and the top of the lifting shaft 7 passes through the crushing box The body 1 is fixedly connected with the lifting motor 6; the lower end of the spiral lifting plate 8 is provided with a horizontally arranged conveyor belt 13 driven by the feeding roller 12, the lifting motor 6 is started, and the lifting motor 6 drives the lifting shaft 7 Rotating, the lifting rotating shaft 7 drives the spiral lifting material plate 8 to rotate, and the lower stone is lifted upward through the spiral lifting mate...

Embodiment 2

[0031] see figure 2 with Figure 5 , a high-efficiency automatic sand making machine, also includes a first shock absorbing mechanism 9 and a second shock absorbing mechanism 19; the first shock absorbing mechanism 9 is arranged under the solid plate on the right side of the screen plate 5, and the second shock absorbing mechanism 19 is arranged below the solid plate on the left side of the sieve plate 5; the internal structure of the first shock absorbing mechanism 9 and the second shock absorbing mechanism 19 is the same, and the lower end of the first shock absorbing mechanism 9 is fixedly connected to the first fixed plate 10, and the second shock absorbing mechanism The lower end of the shock mechanism 19 is fixedly connected to the second fixed plate 18;

[0032] The first damping mechanism 9 includes a damping sleeve 22 and a movable rod 21; the movable rod 21 is inserted into the interior of the damping sleeve 22 from the top of the damping sleeve 22, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com