Raw material crushing device for preparing environment-friendly bricks

A crushing device and technology of environmentally friendly bricks, which are applied in the production of ceramic materials, climate sustainability, sustainable waste treatment, etc., can solve the problems of affecting work efficiency, poor crushing effect, and a large amount of dust generated by small particles of raw materials. The effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

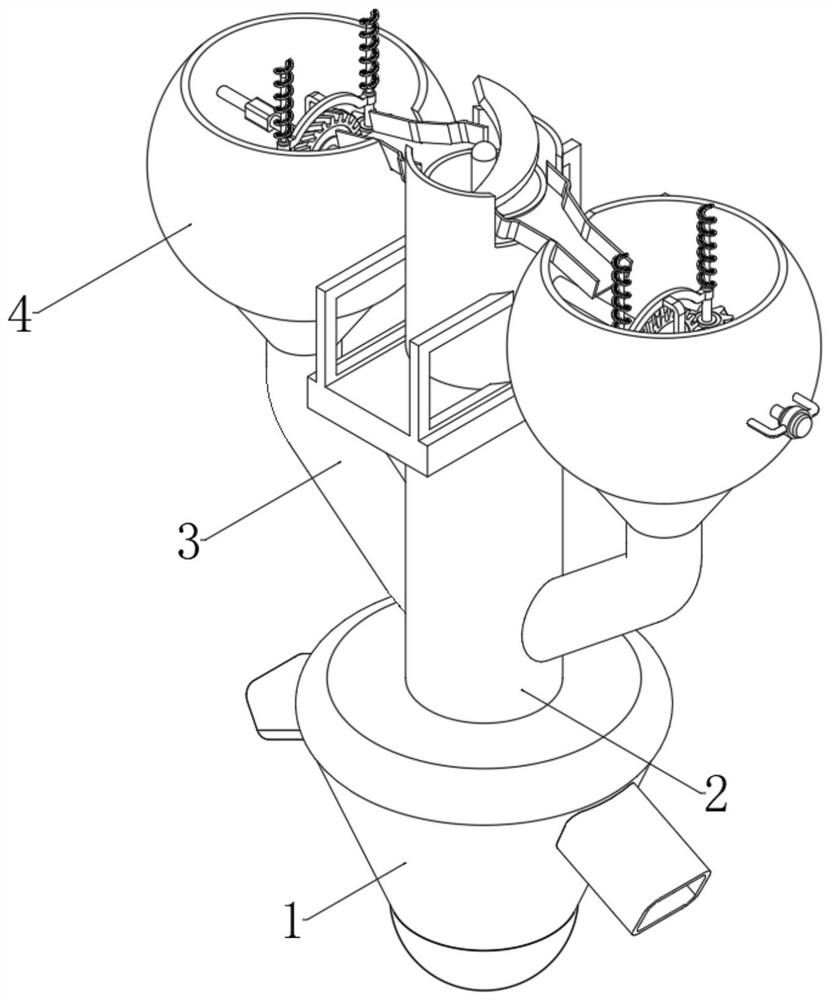

[0033] see Figure 1-5 , a raw material crushing device for the preparation of environmentally friendly bricks, comprising a collection hopper 1, a collection chamber 101 is arranged in the collection hopper 1, discharge pipes 6 are arranged obliquely on both sides of the collection hopper 1, and two groups of crushing spheres 4 are arranged above the collection hopper 1 The crushing sphere 4 is provided with a crushing assembly 8, the lower end of the crushing sphere 4 is fixedly connected with a connecting pipe 3, the upper center of the collecting hopper 1 is fixedly connected with a feeding pipe 2, and the lower end of the connecting pipe 3 is in communication with the side wall of the feeding pipe 2, Both sides of the upper end of the feeding pipe 2 are provided with installation grooves 9, and a feeding channel 7 is arranged in the installation groove 9, and the feeding channel 7 is inclined downward and is fixedly connected with the connecting groove 10 at the upper end ...

Embodiment 2

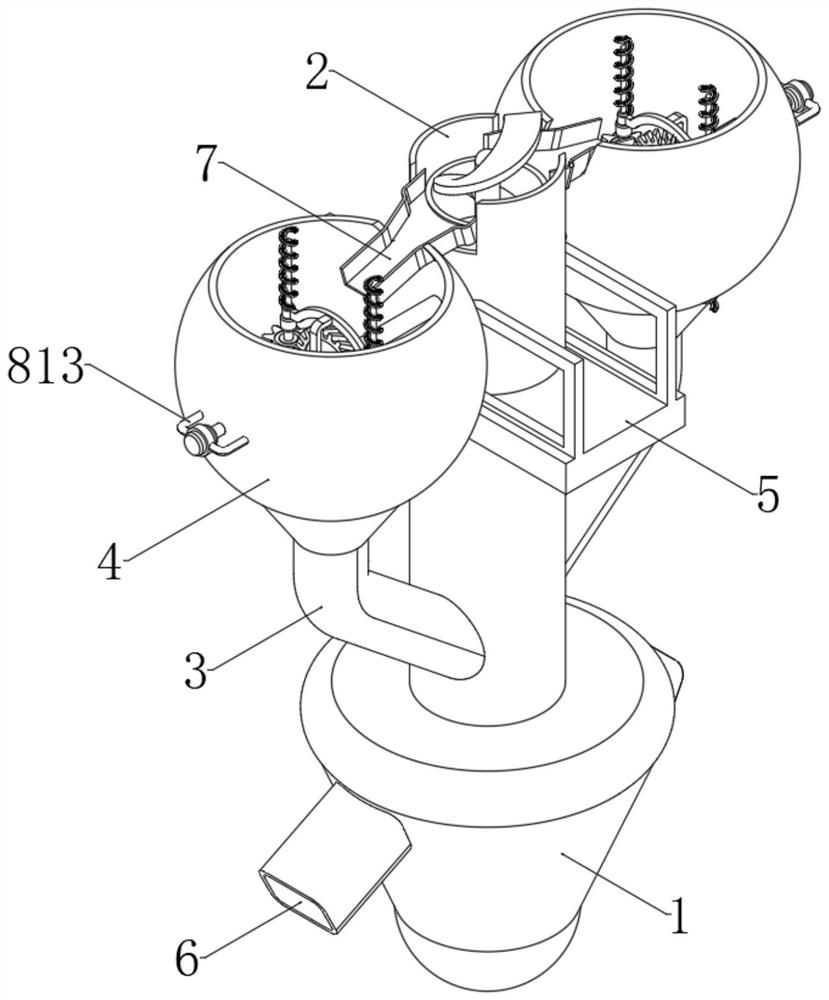

[0037] Such as Figure 5-7 As shown, the differences based on Embodiment 1 are:

[0038] A mounting plate 5 is fixedly connected to the feeding pipe 2, and the mounting plate 5 is arranged between two groups of crushing spheres 4; side brackets 501 are fixedly connected to both ends of the upper side of the mounting plate 5, and a feeding channel 503 is opened in the center of the mounting plate 5 , the two sets of side brackets 501 are respectively located on both sides of the feeding channel 503;

[0039]The inside of the feeding pipe 2 is provided with a built-in pipe 201, and the built-in pipe 201 and the feeding pipe 2 are fixed by connecting rods. The built-in pipe 201 is provided with a feeding cavity 204; the center of the built-in pipe 201 is provided with a feeding auger 202, The center of the material auger 202 is fixedly connected with a transmission shaft 203, the lower end of the transmission shaft 203 is fixedly connected with the upper end of the output shaft ...

Embodiment 3

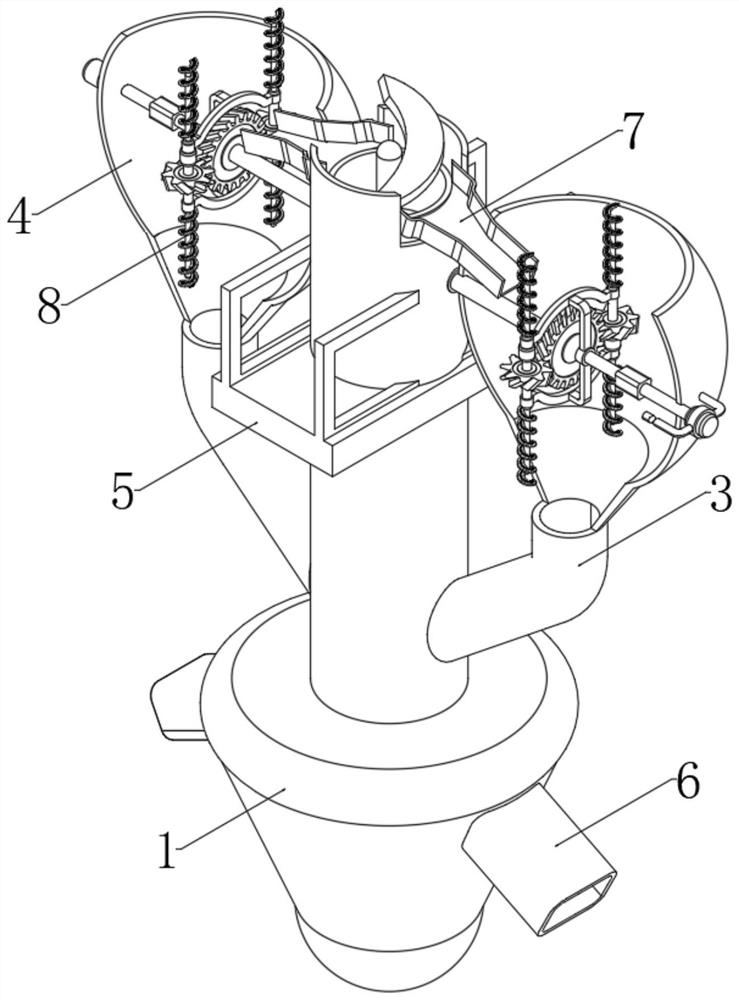

[0044] Such as Figure 8-10 As shown, based on embodiment 1-2, what is different is:

[0045] The crushing assembly 8 includes a transmission rod A804 and a transmission rod B805. The transmission rod A804 and the transmission rod B805 respectively move through the side wall of the crushing sphere 4; The rear side of the motor B803 is fixedly connected to the outer side of the crushing sphere 4 through the mounting bracket 813, and the motor A502 is fixedly connected to the center of the upper side of the side bracket 501;

[0046] The transmission rod B805 moves through the stabilizing block 806, and the lower side of the stabilizing block 806 is fixedly connected with the inner wall of the crushing sphere 4 through the connecting frame 808; frame 810, and the two ends of the edge frame 810 are fixedly connected with mounting rings 812;

[0047] The connecting shaft 814 is movably connected in the installation ring 812, and the center of the connecting shaft 814 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com