Method for gluing peripheral surface of pipe

A technology for gluing and pipe fittings, applied in the field of pipe fittings processing, can solve the problems of unfavorable production cost saving, material waste, complicated processes, etc., and achieve the effects of cost saving, pollution reduction, and irritating smell reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

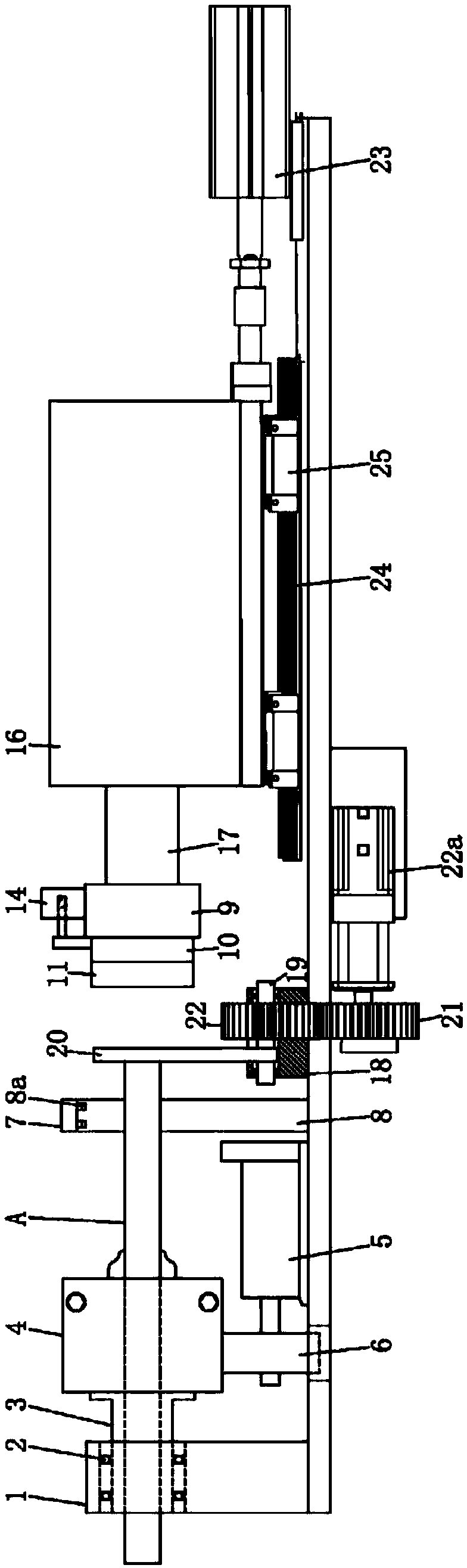

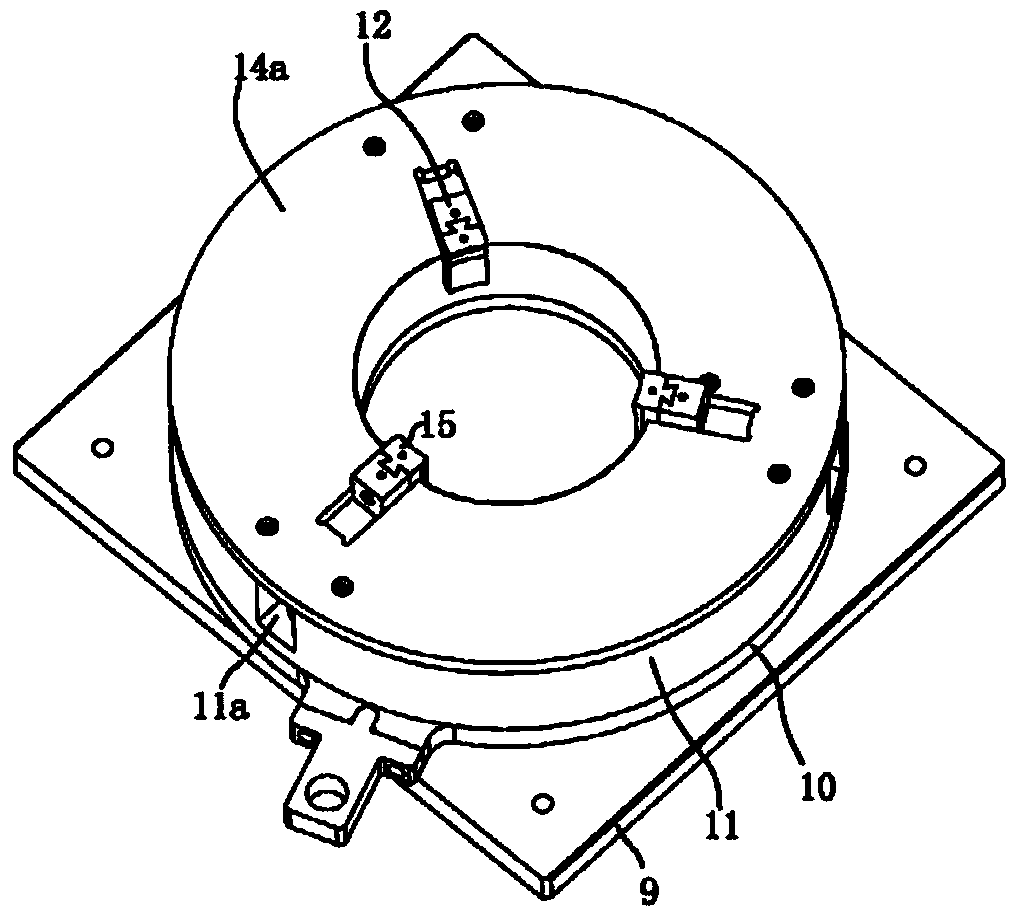

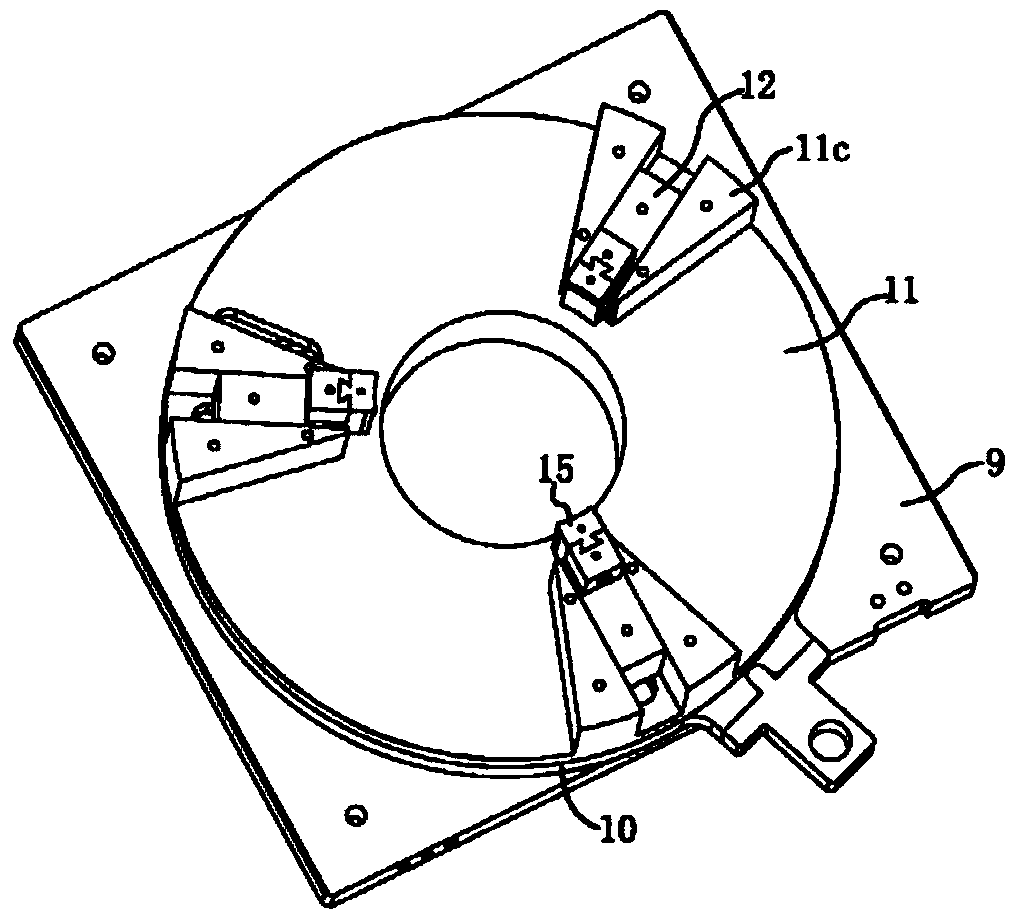

[0023] The method for applying glue to the peripheral surface of pipe fittings of the present invention comprises the following steps:

[0024] After passing one end of the pipe fitting through the support seat, the hollow shaft and the chuck in sequence, the pipe body of the pipe fitting is clamped by the chuck of the chuck to form a distance of 0.5 to 3 mm between the gluing working part of the gluing mechanism and the surrounding surface of the pipe fitting , one end of the gluing mechanism is connected to the mounting seat; the glue is delivered to the peripheral surface of the pipe through the glue feeding mechanism; the chuck or the hollow shaft is driven to rotate through the first driving mechanism, and the glue on the surface of the rotating pipe is brushed by the gluing mechanism The driving mechanism drives the rotating shaft to drive the gluing mechanism to rotate, and when the gluing mechanism rotates, the gluing working part of the gluing mechanism brushes the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com