Cleaning device for chemical reaction kettle

A cleaning device and chemical reaction technology, applied in chemical/physical/physical-chemical fixed reactors, cleaning hollow objects, chemical instruments and methods, etc. It does not have the problem of scraping the attachment device, etc., to achieve the effect of wide range of use and prevention of incomplete bottom cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

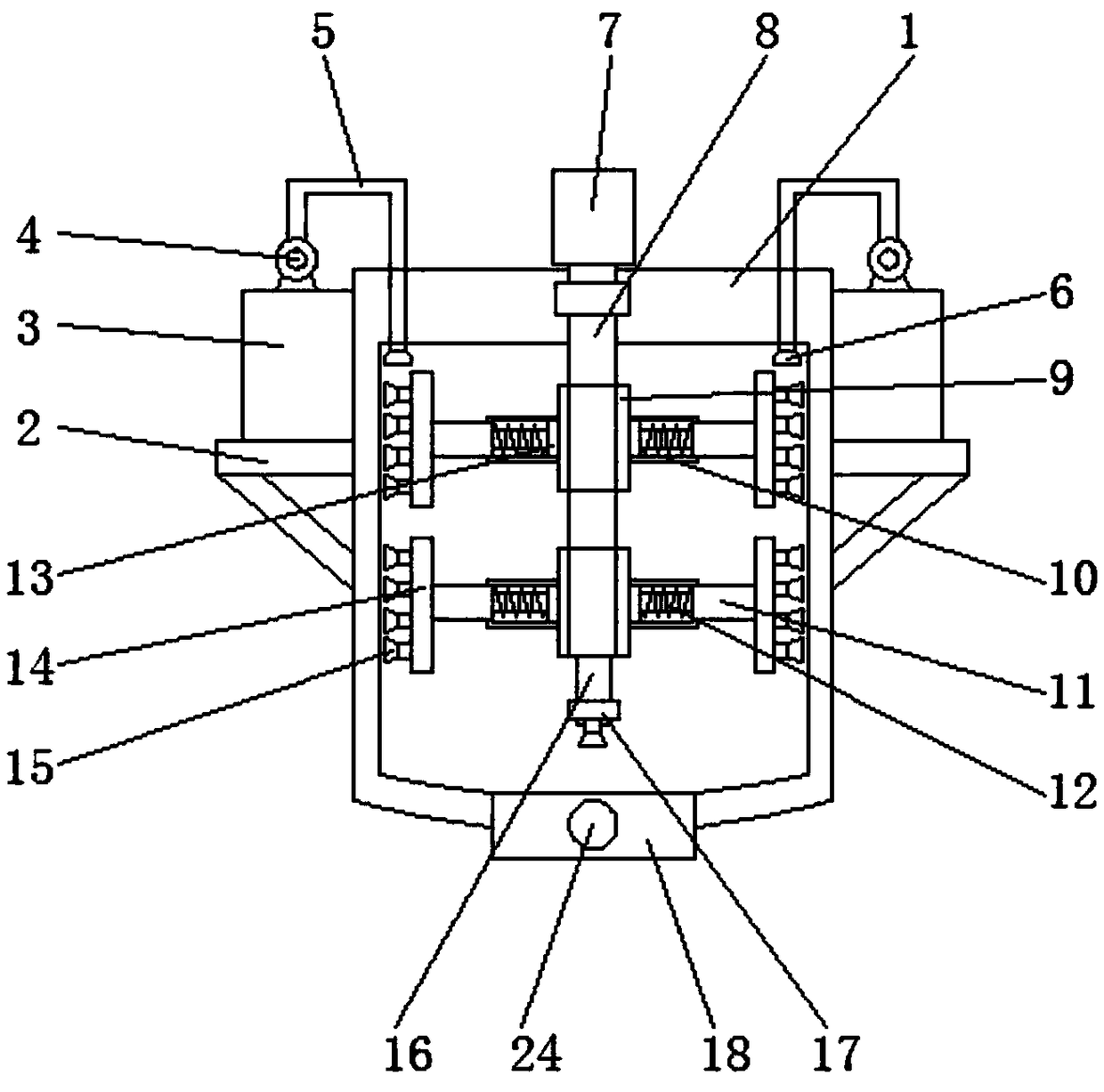

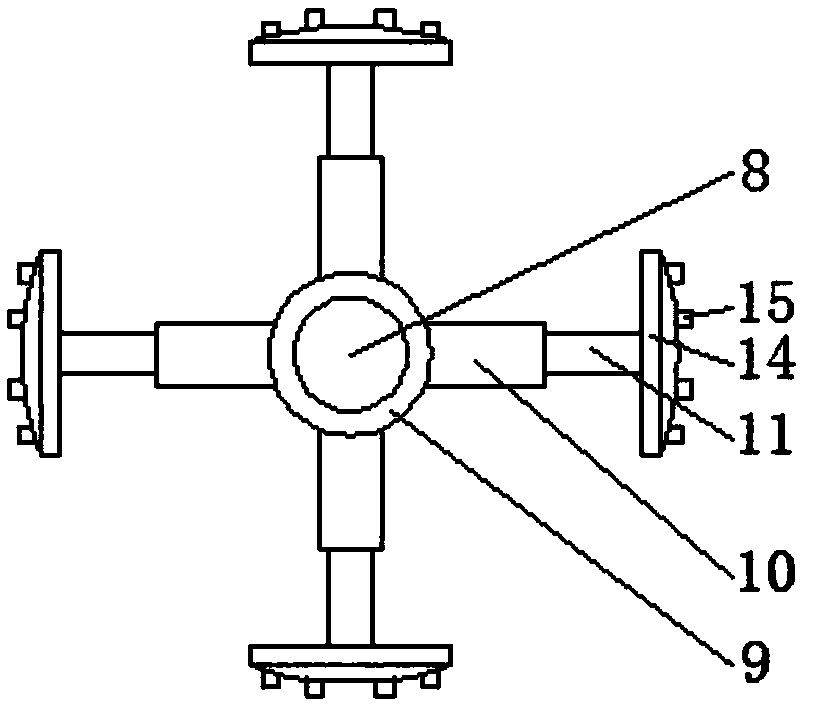

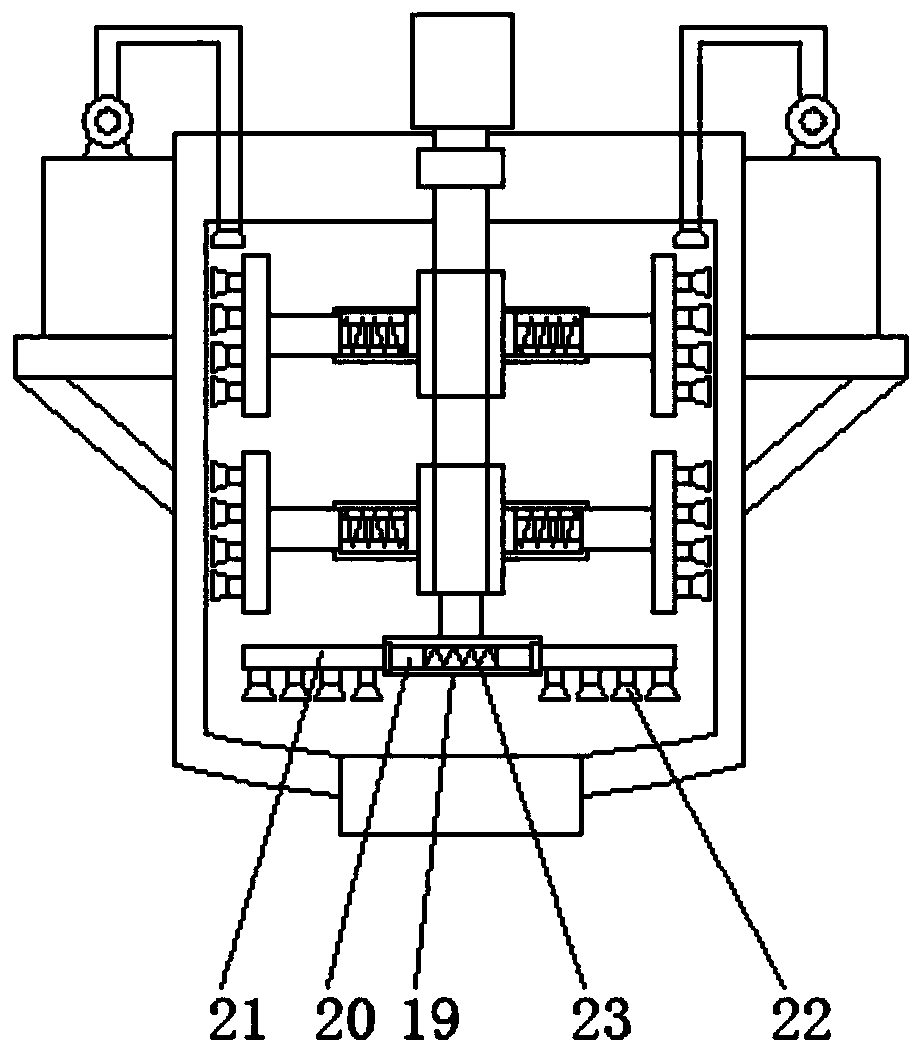

[0022] Example: refer to Figure 1-3 , the present invention provides a kind of technical scheme, a kind of cleaning device for chemical reactor, comprises reactor 1, and both sides of reactor 1 are symmetrically provided with auxiliary support 2, and the top of auxiliary support 2 is provided with water storage tank 3, The top of the water storage tank 3 is provided with a water pump 4, the top of the water pump 4 is connected with a water delivery pipe 5, and the end of the water delivery pipe 5 runs through the top of the reaction kettle 1 and extends to the inside of the reaction kettle 1. A nozzle 6 is connected to the top of the reaction kettle 1 There is a rotating motor 7 in the center, the output shaft of the rotating motor 7 runs through the top of the reactor 1 and is connected with a stirring shaft 8, the stirring shaft 8 is a hollow structure, and the outer side of the stirring shaft 8 is sequentially provided with at least two first sets of The outer side of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com