Efficient and safe flushing device for new materials

A technology of flushing device and new material, applied in drying gas arrangement, dryer, grain processing and other directions, can solve problems such as affecting the use of new materials, containing impurities, etc., to improve preservation effect, improve purity, and improve work efficiency and effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

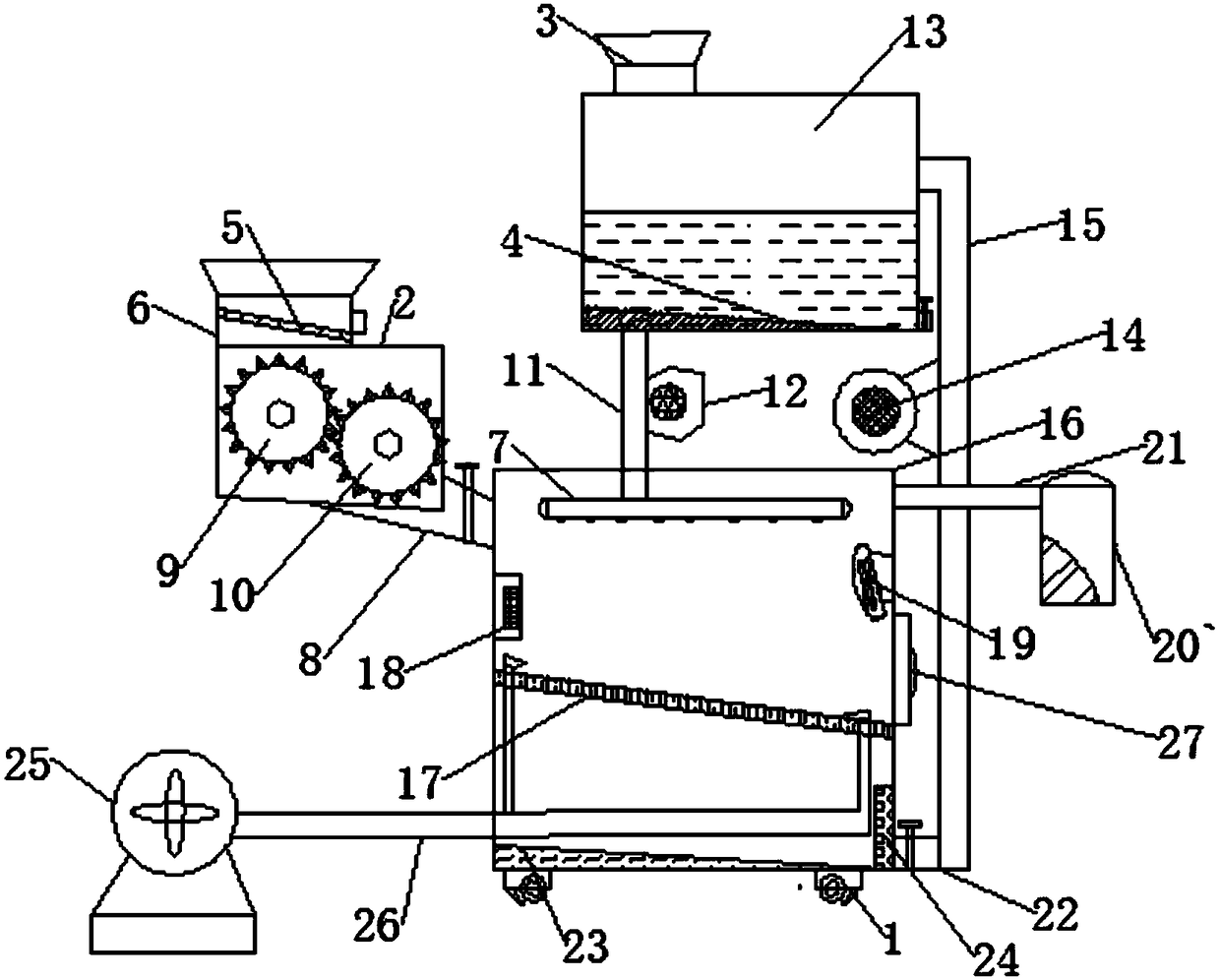

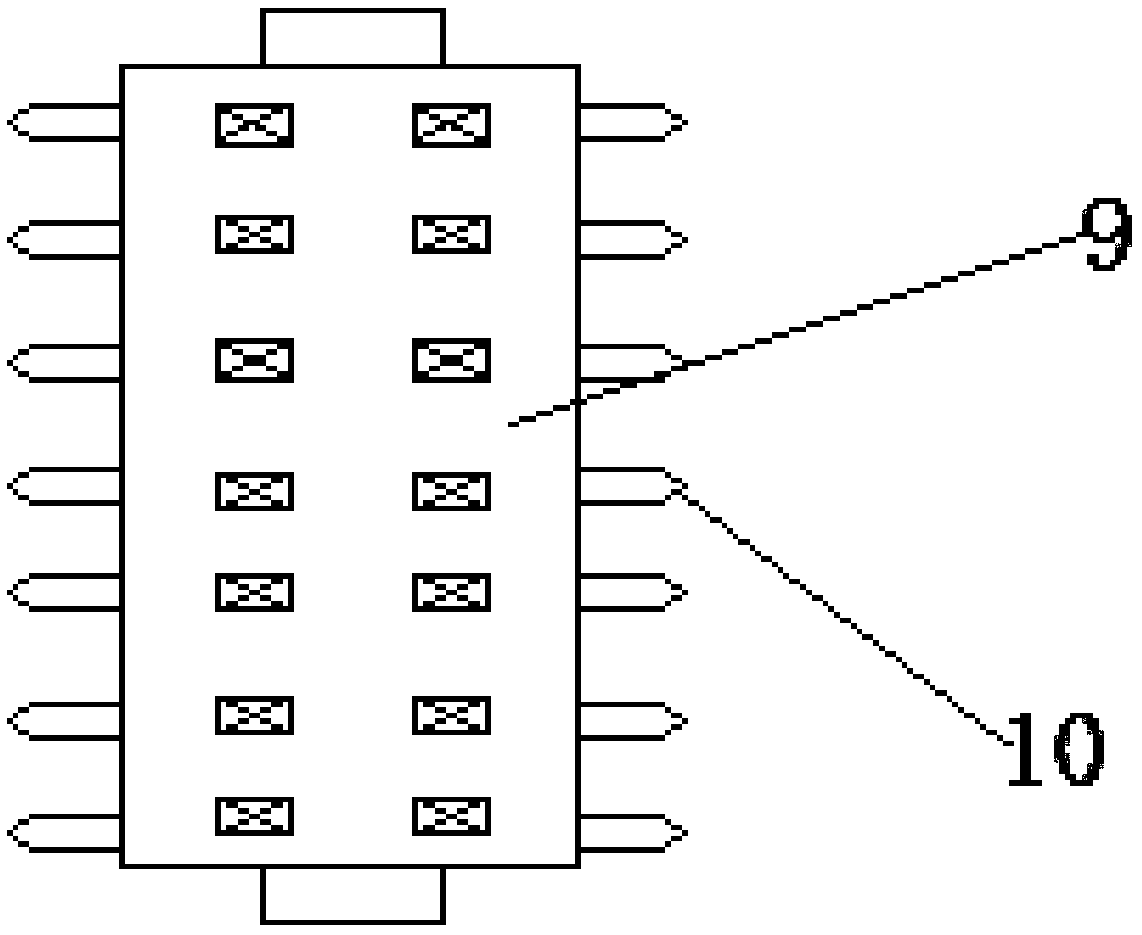

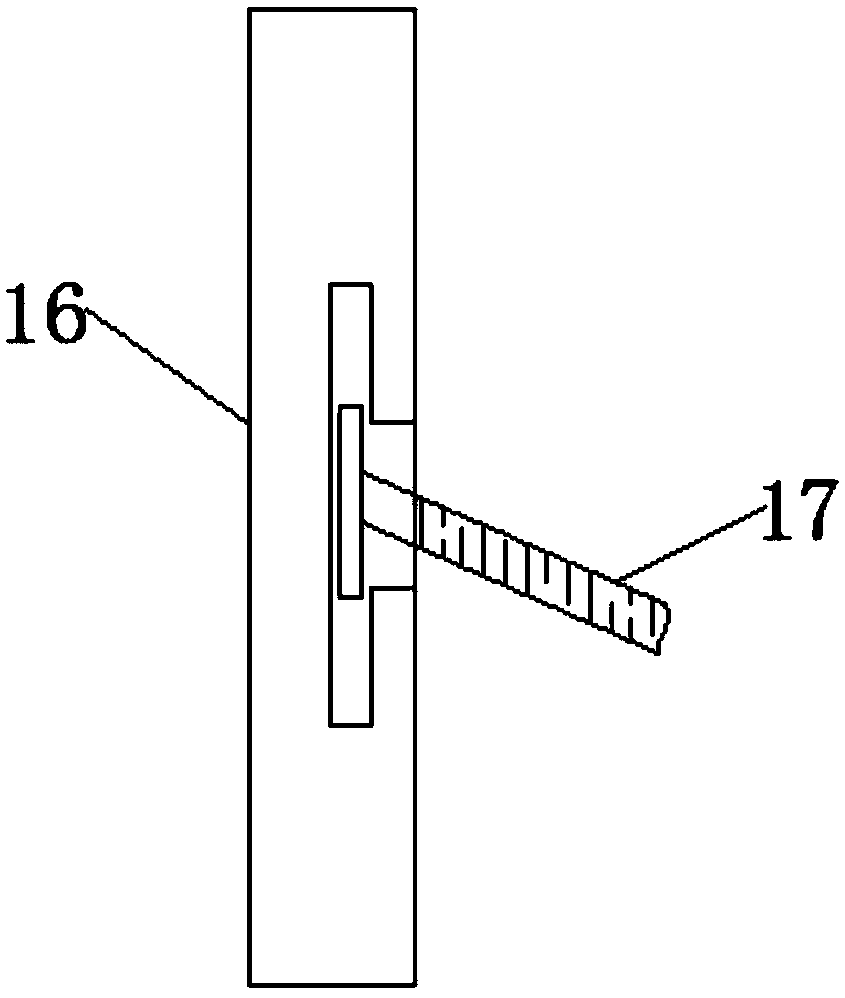

[0019] see Figure 1-3 , a high-efficiency and safe flushing device for new materials, including crushing box 2, spray discharge 7, feeding pipe 8, crushing roller 9, crushing teeth 10, water spray pipe 11, booster pump 12, water tank 13, return pipe 15, cleaning Box 16, filter plate 17, drier 18, blower fan 19, gas collection tank 20 and blower 25, the top of described crushing box 2 is provided with feeding pipe 6, and the inside of feeding pipe 6 is inclined to be provided with grid 5, The lowest end of the grid 5 is provided with a large block discharge pipe, and the new material is put into the crushing box 2 through the feed pipe 6, and the large block of material is discharged under the action of the grid 5 to improve the purity of the new material, and the crushing box 2 There are multiple groups of crushing rollers 9 installed inside. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com