Extrusion casting device

A squeeze casting and connecting device technology, which is applied in the field of casting modeling, can solve problems such as mold damage and casting object damage, and achieve the effect of convenient mutual combination and separation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

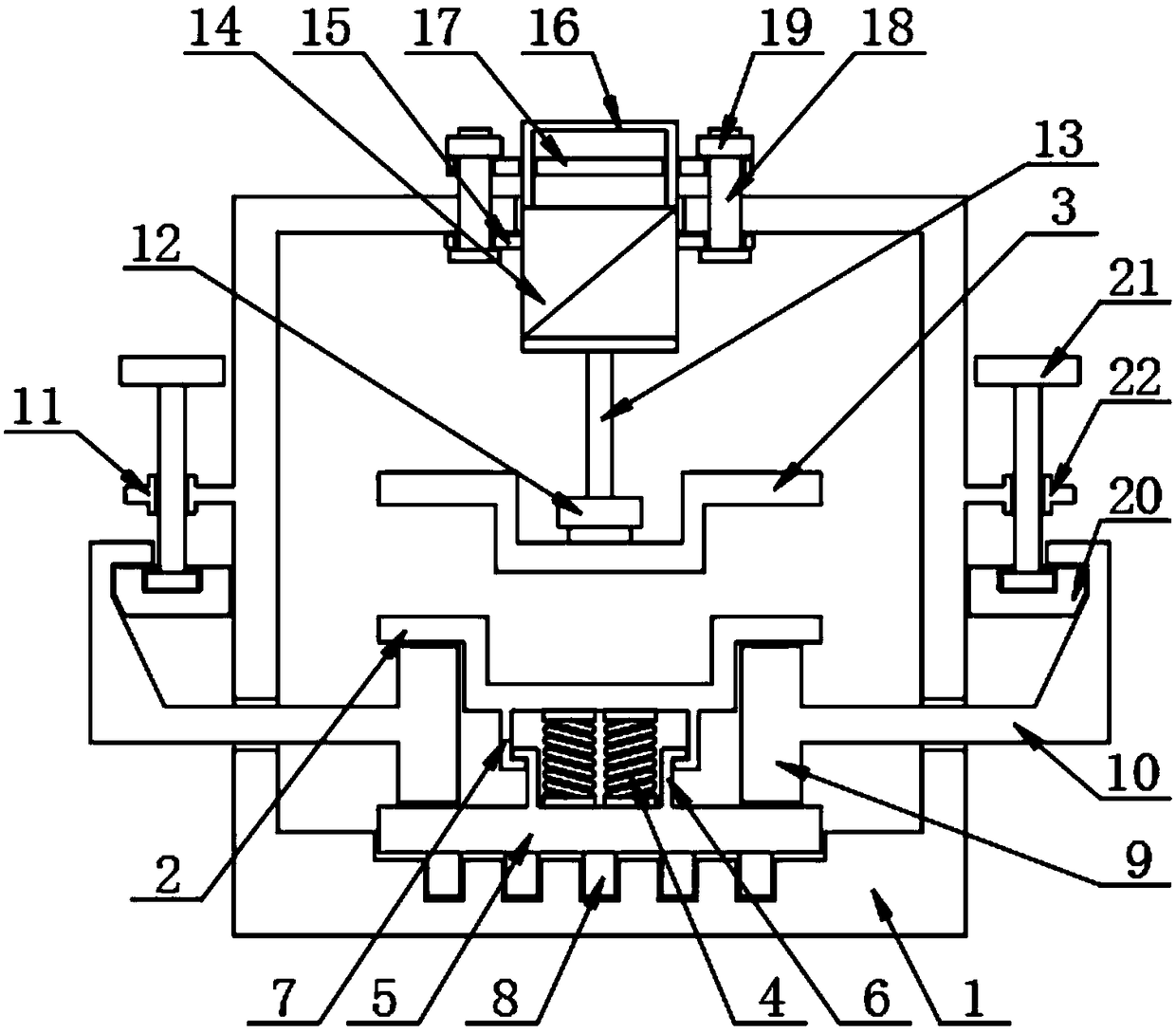

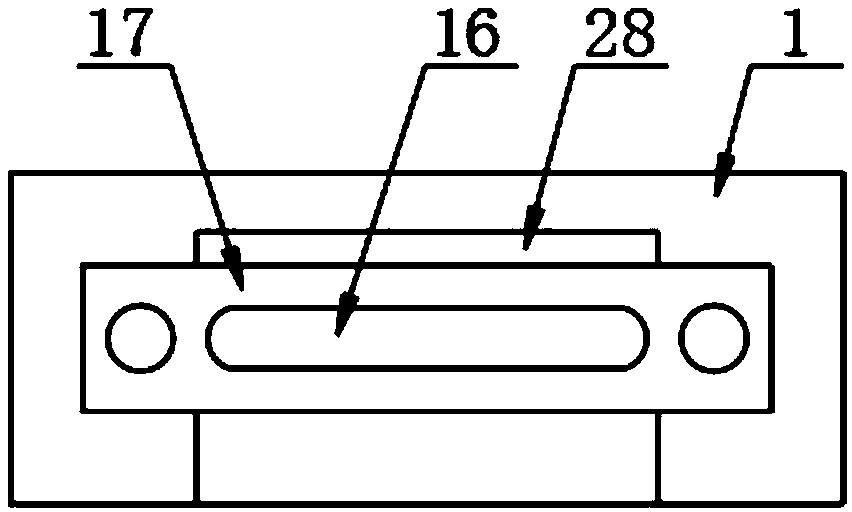

[0024] The present invention provides such as Figure 1-4 A squeeze casting device shown includes a bracket 1, a lower mold 2 is arranged inside the bracket 1, an upper mold 3 is arranged on the top of the lower mold 2, and a first spring 4 is arranged on the bottom of the lower mold 2, The bottom of the first spring 4 is provided with a bottom plate 5, the outside of the first spring 4 is provided with a lower lever 6, the top of the lower lever 6 is provided with an upper lever 7, and the bottom of the bottom plate 5 is provided with a protruding lever 8 , both sides of the top of the bottom plate 5 are provided with support blocks 9, one side of the support block 9 is provided with a pull frame 10, the inner side of the pull frame 10 is provided with a moving device 11, and the top of the upper mold 3 is provided with a connecting device 12, The top of the connecting device 12 is provided with a telescopic rod 13, the top of the telescopic rod 13 is provided with a cylinder...

Embodiment 2

[0027] The moving device 11 includes a moving block 20, the top of the moving block 20 is provided with a rotating rod 21, and the outside of the support 1 is provided with a support plate 22, and the rotating rod 21 is matched with the pull frame 10 through the moving block 20, and rotates Rod 21, and then rotating rod 21 drives moving block 20 to move down through support plate 22, and moving block 20 pulls support block 9 to break away from lower mold 2 through pull frame 10, reaches the decompression effect to lower mold 2.

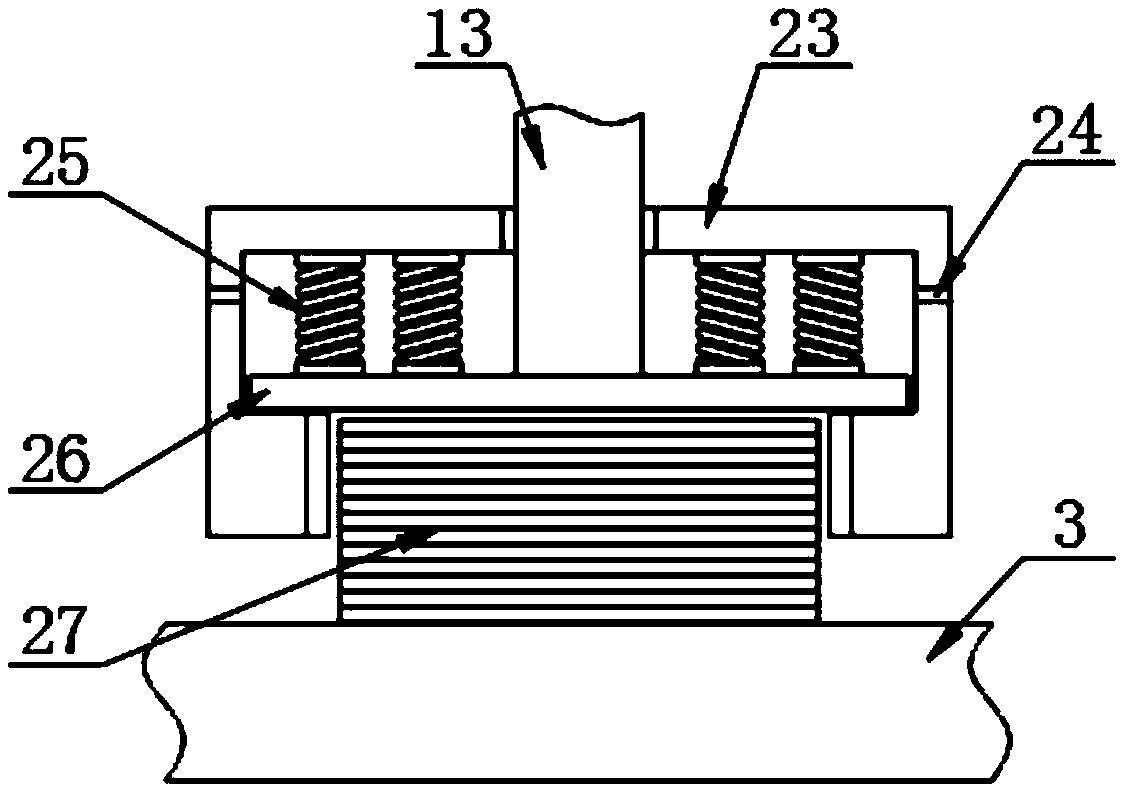

[0028] The connecting device 12 includes a rotary sleeve 23, the outer surface of the rotary sleeve 23 is provided with an oil hole 24, the inner side of the rotary sleeve 23 is provided with a second spring 25, and the bottom of the second spring 25 is provided with a pressing plate 26. The top surface of the upper die 3 is provided with a screw block 27, and the rotary sleeve 23 is threadedly connected with the screw block 27, and the rotary sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com