A dust suppression spray fan heating support for digital media display

A digital media and spray fan technology, applied in non-variable displacement pumps, non-displacement pumps, liquid fuel engines, etc., can solve the problems of unsatisfactory cooling effect of flowing air and easy crash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

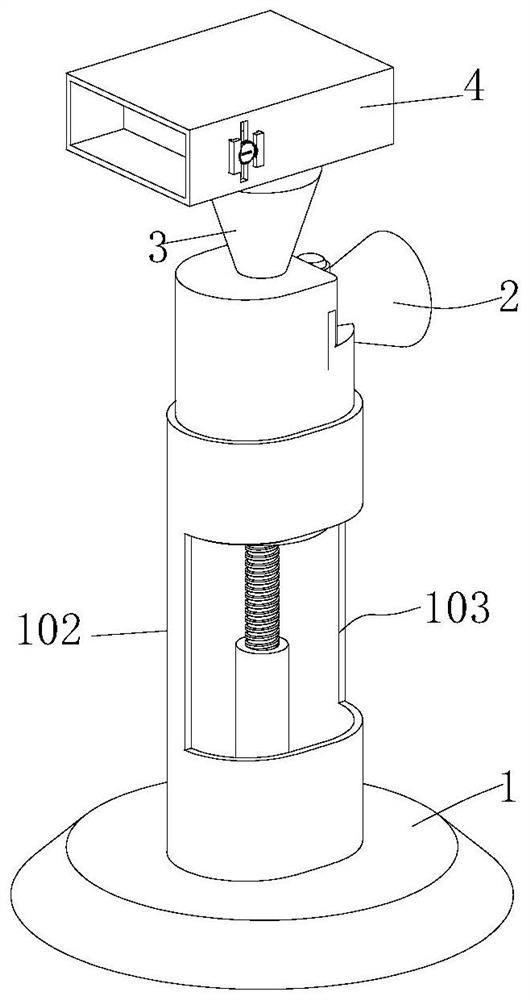

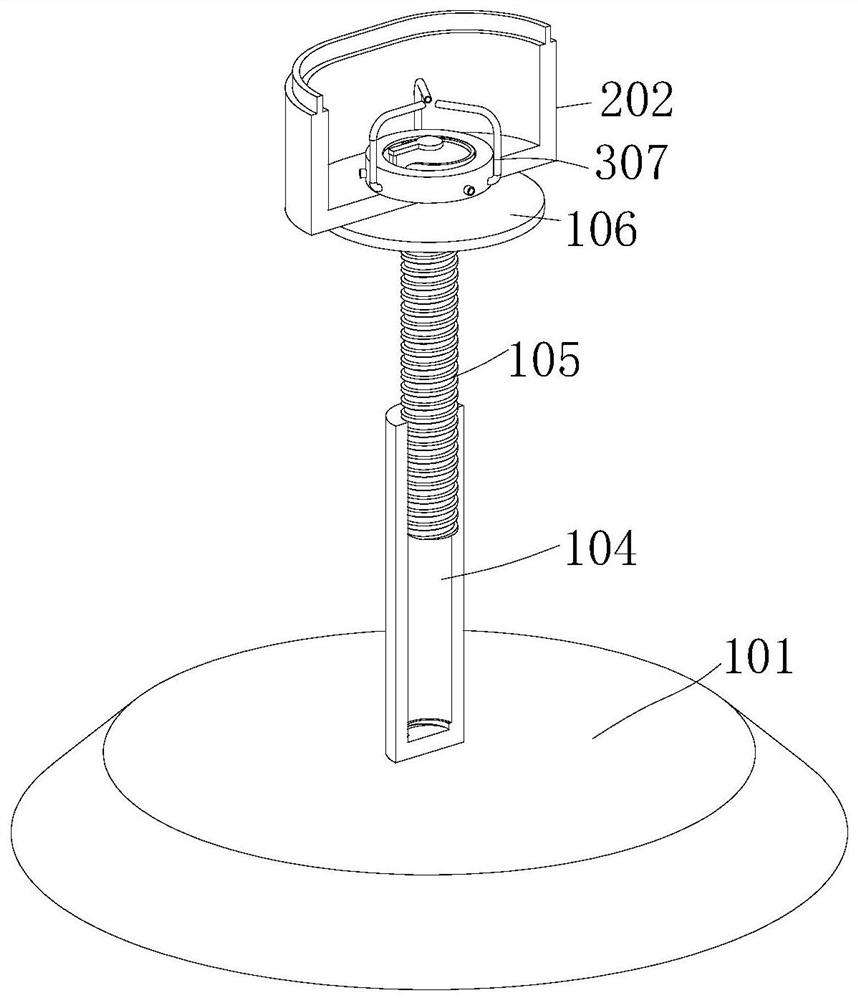

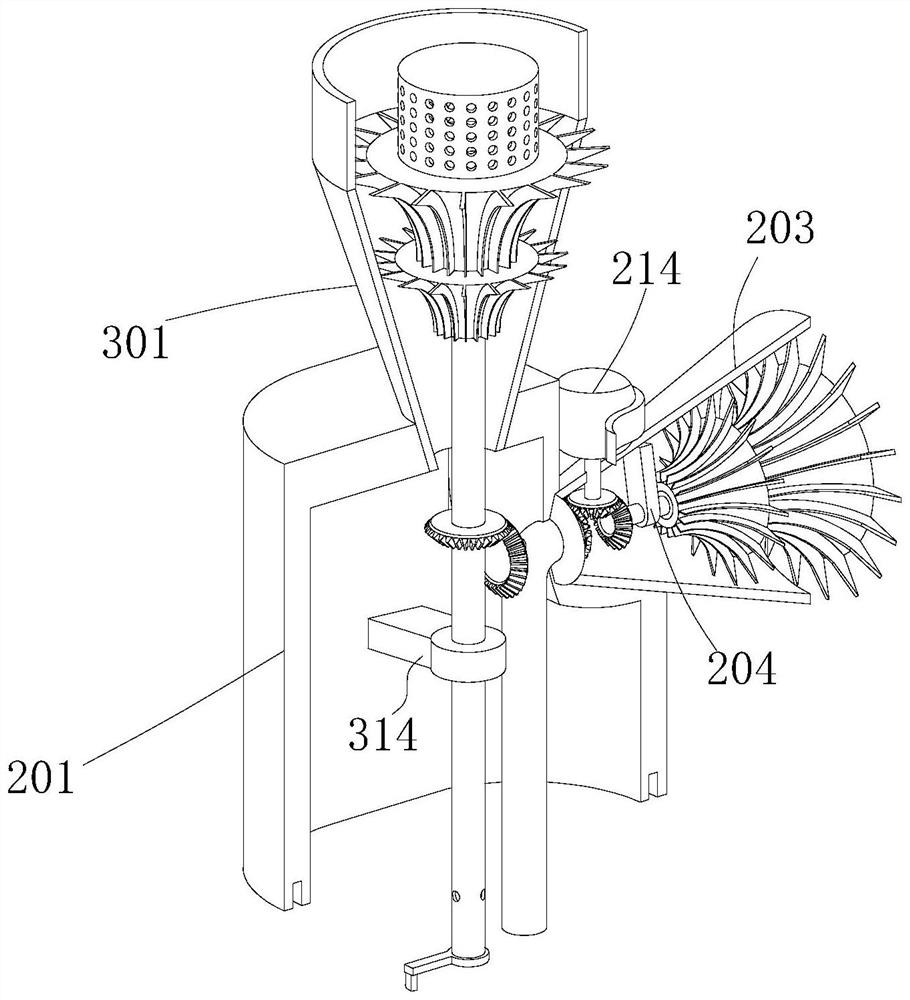

[0028] Embodiment one, such as Figure 1-8As shown, it includes a support mechanism 1, a dust suppression mechanism 2 is fixedly installed on the inside of the support mechanism 1, and a spray mechanism 3 is fixedly installed above the inside of the support mechanism 1, and the spray mechanism 3 is sleeved inside the dust suppression mechanism 2. The top of the spray mechanism 3 The drying mechanism 4 is connected and penetrated. The support mechanism 1 includes a support platform 101. The upper surface of the support platform 101 is fixedly equipped with a support sleeve 102. The upper surface of the support platform 101 is located inside the support sleeve 102 and is fixedly equipped with a threaded sleeve 104. The threaded sleeve The inside of the barrel 104 is threaded with a threaded shaft 105, and the top of the threaded shaft 105 is rotatably connected with a tray 106. The dust suppression mechanism 2 includes a casing 201, which is fixedly sleeved above the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com