An air cooler string cooling tower cooling system for HVDC converter valve

An air cooler and cooling system technology, which is applied to electrical components, output power conversion devices, electrical equipment structural components, etc. Efficiency and the effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

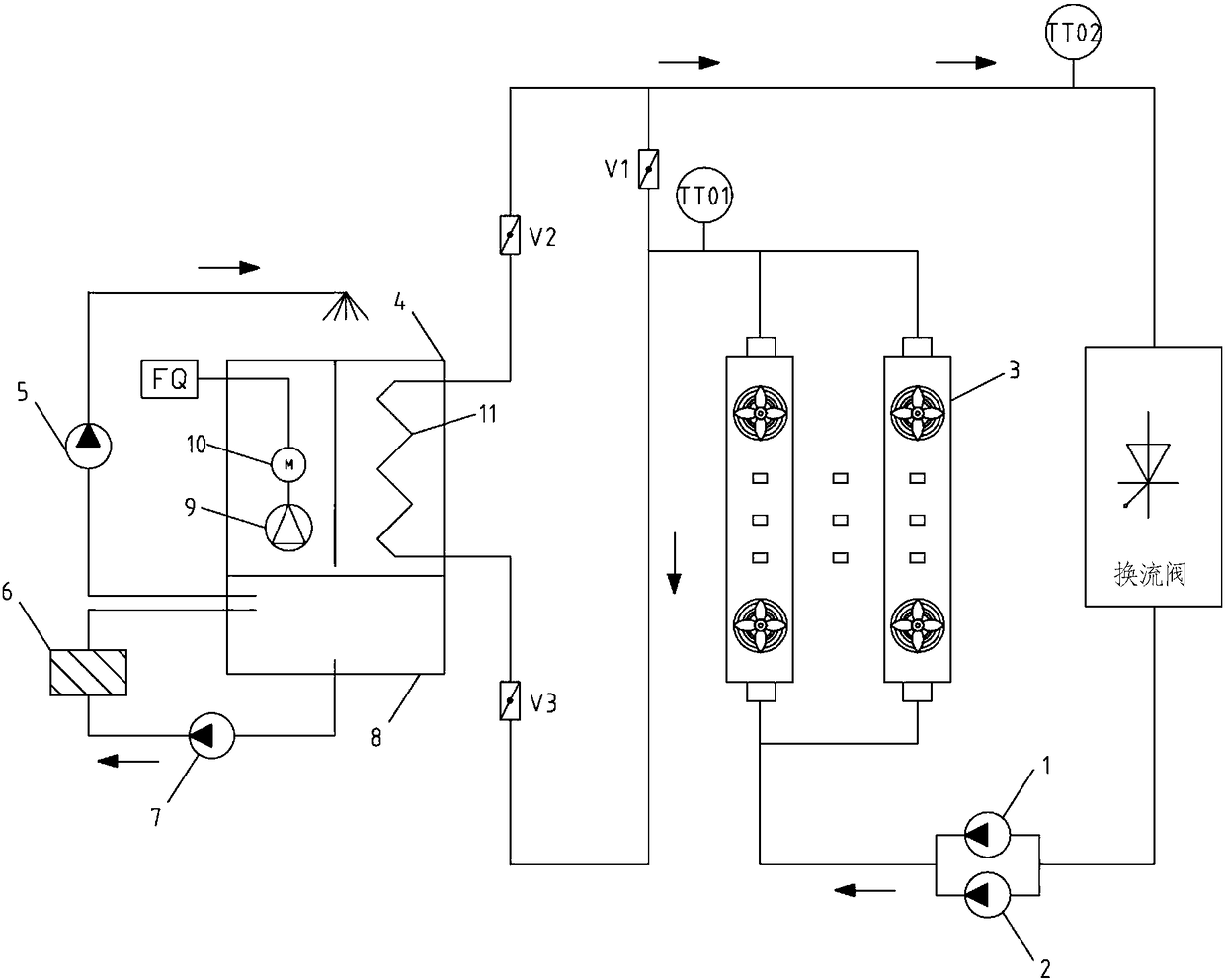

[0021] This embodiment provides an air cooler series cooling tower cooling system for DC power transmission converter valves, which is used to dissipate heat for DC power transmission converter valves, wherein the DC power transmission converter valves can be thyristor converter valves, IGBT converter valves , IGCT converter valve, IGET converter valve and other principles and forms of converter valves.

[0022] The cooling system mainly includes two parts, one is the air cooler subsystem, and the other is the closed cooling tower subsystem. Wherein, in order to ensure cooling efficiency and cooling reliability, the air cooler subsystem is composed of at least two redundantly arranged air coolers 3, such as figure 1 shown. The closed cooling tower subsystem includes a closed cooling tower and other related parts. The closed cooling tower is a closed evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com