Mobile metal liquid automatic casting device

A metal liquid and mobile technology, applied in metal processing equipment, equipment for supplying molten metal, casting equipment, etc., can solve the problems of shortening the cooling time of castings and difficult casting control, so as to ensure health, improve casting production efficiency, The effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

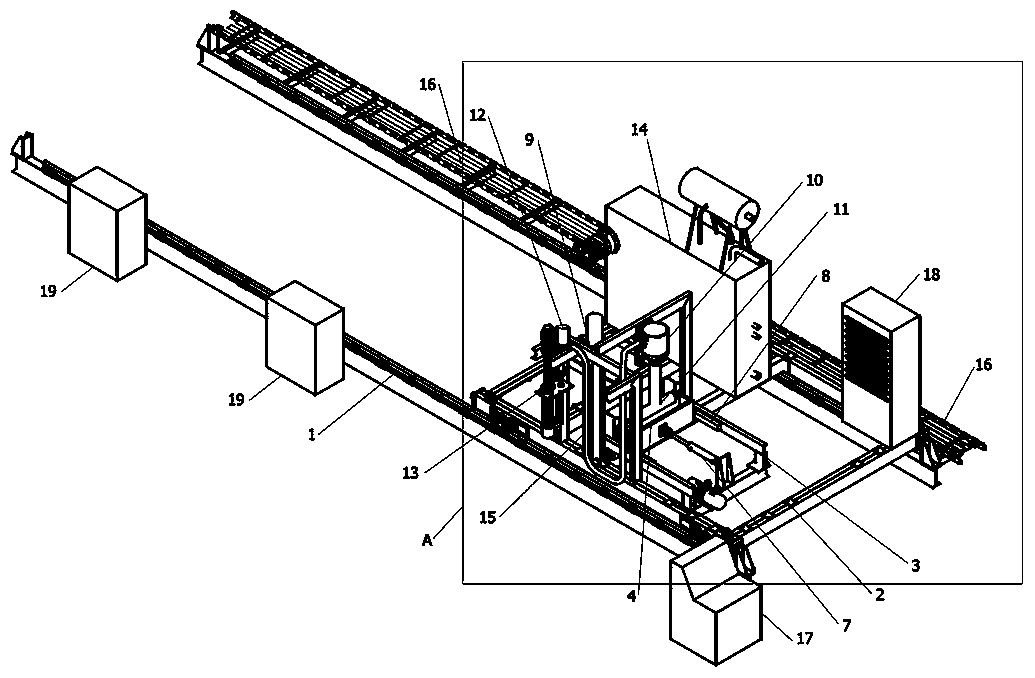

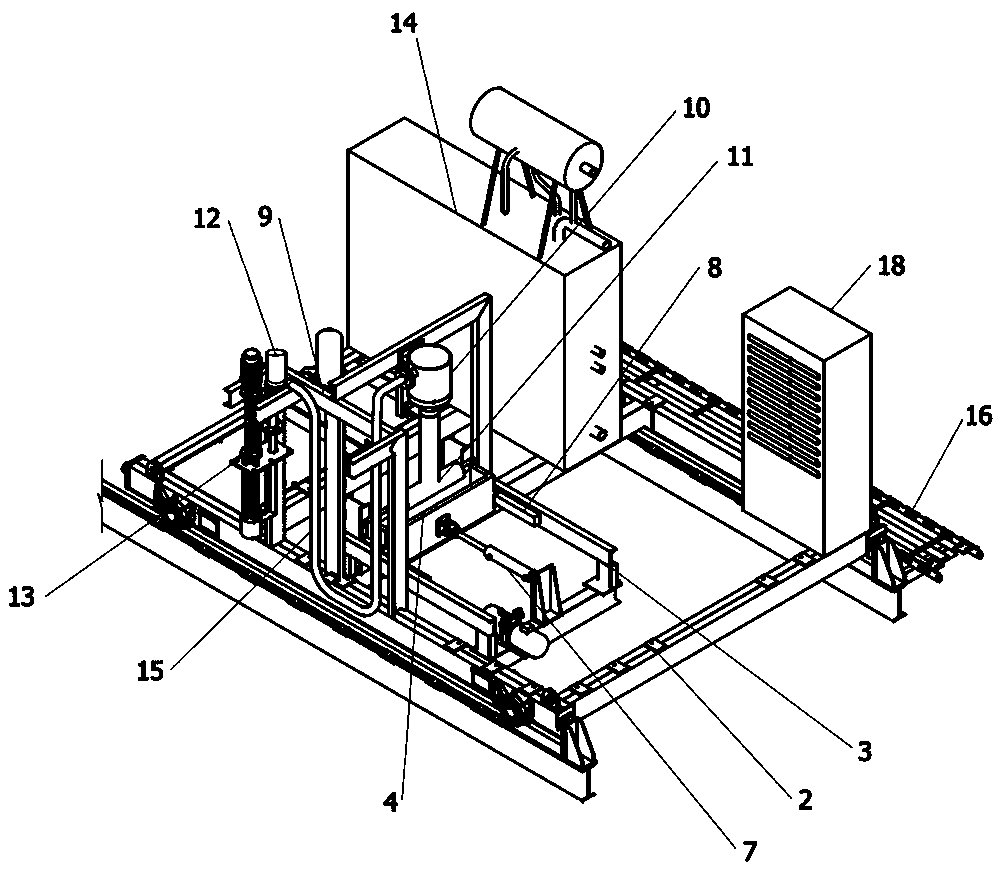

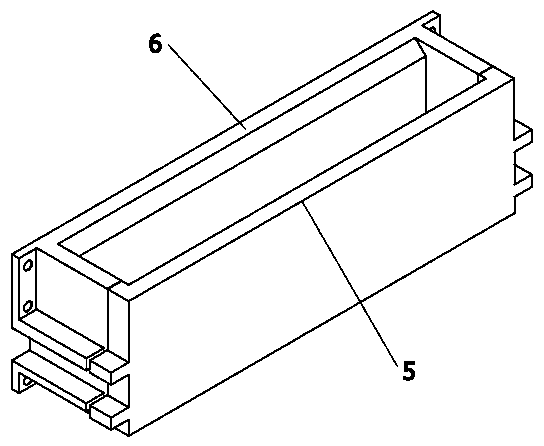

[0012] as attached Figure 1~3 The mobile automatic molten metal casting device shown includes running track 1, carrying trolley 2, mold support 3, casting mold 4, mold opening and closing control mechanism 7, suspension bracket 9, casting mechanism, liquid supply pump 13, mold temperature control device 14 and a control device, the running track 1 is symmetrically arranged on the ground or the installation foundation of the workshop, the carrying trolley 2 is arranged on the running track 1, the carrying trolley 2 can reciprocate along the running track 1, and the mold support 3 Set on the carrying trolley 2, the casting mold 4 and the mold opening and closing control mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com