Flexible gear machining clamp

A flexible processing and gear technology, applied in manufacturing tools, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of chuck and fixture seat wear, increased fixture cost, and insignificant expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

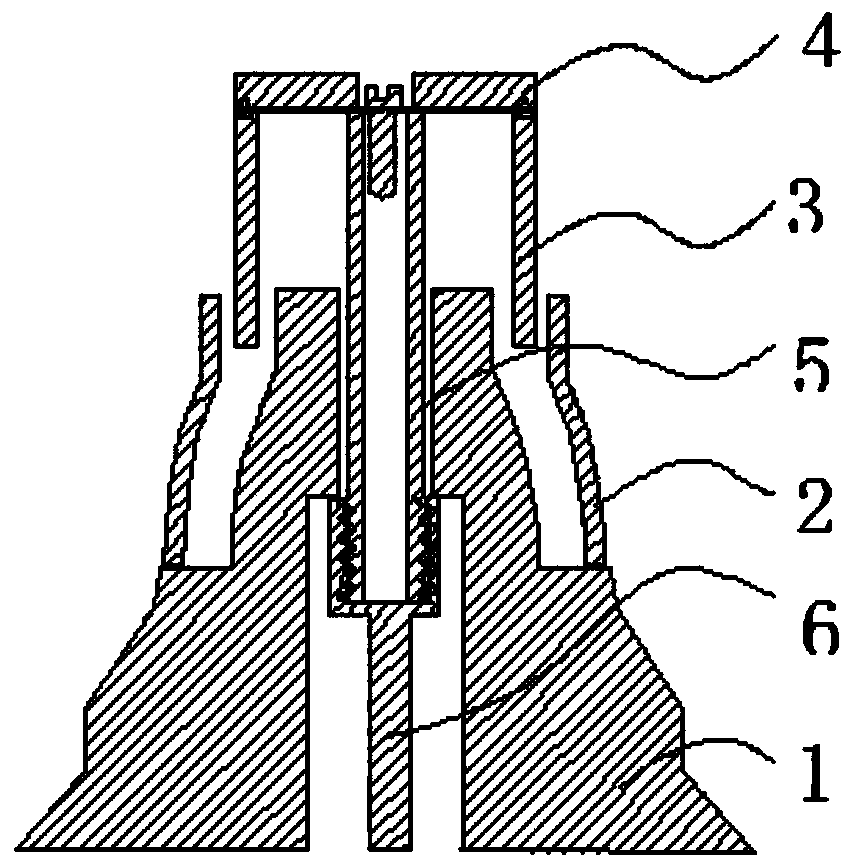

[0023] In specific implementation, such as figure 1 A gear flexible processing fixture shown includes an expansion sleeve 3, the expansion sleeve 3 is cylindrical, and is composed of several steel blocks, and the adjacent steel blocks are bonded with adhesive strips; the fixture seat 1, A center tie rod 6 is arranged inside the clamp seat 1, a gland 4 is arranged on the expansion sleeve 3, and a connecting rod 5 connected with the center tie rod 6 is arranged on the gland 4, under the action of the telescopic device, the center The tie rod 6 can drive the gland 4 to press down through the connecting rod 4, so that the gland 4 acts on the expansion sleeve 3 and moves the expansion sleeve 3 downward; the upper end of the clamp seat 1 has a tapered section, and the upper end of the tapered section The outer diameter of the outer diameter of the expansion sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com