Automatic assembling process of wall washer light and assembling equipment of wall washer light

A technology for automatic assembly and wall washer, applied in metal processing equipment, assembly machines, metal processing and other directions, it can solve problems such as labor consumption, inconsistent product quality, screw tilt, etc., to avoid human errors, improve production efficiency, and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

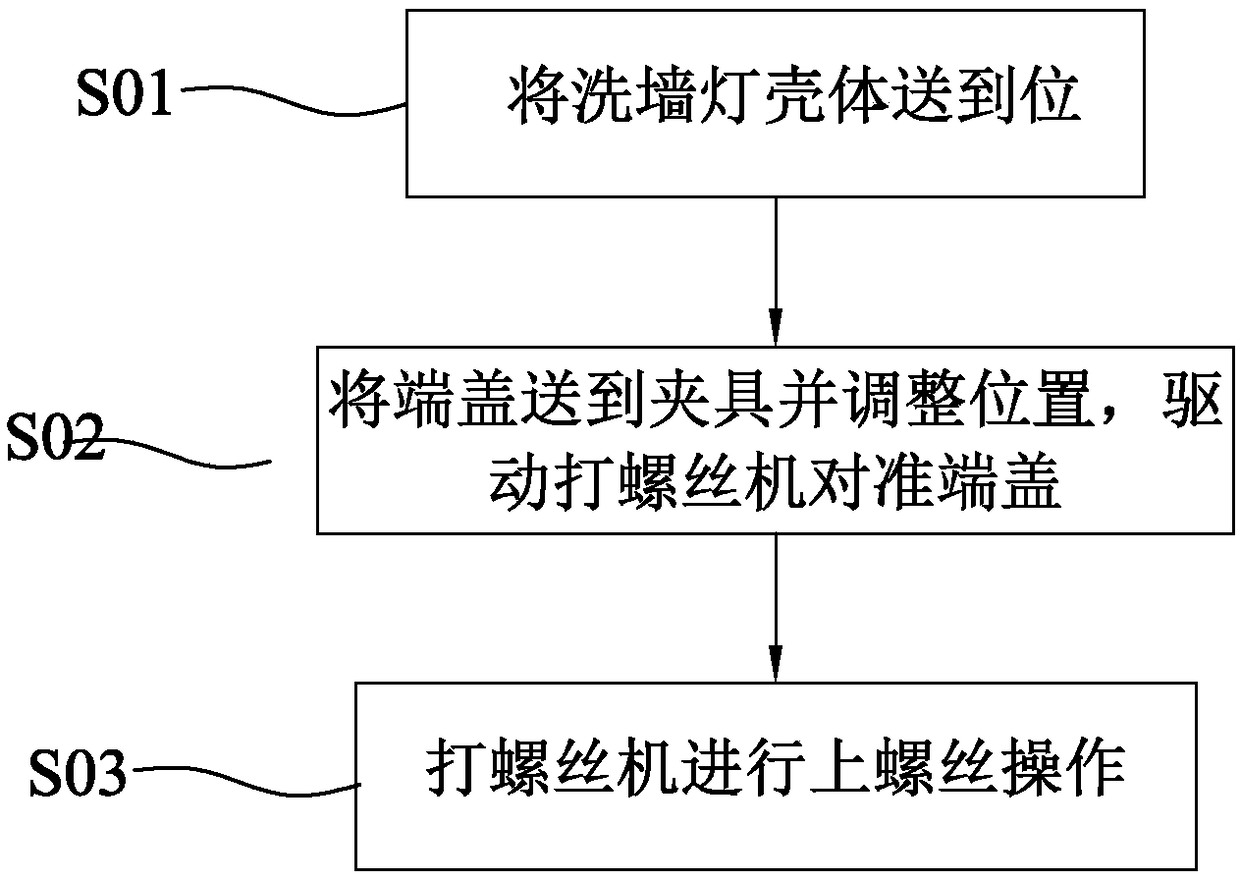

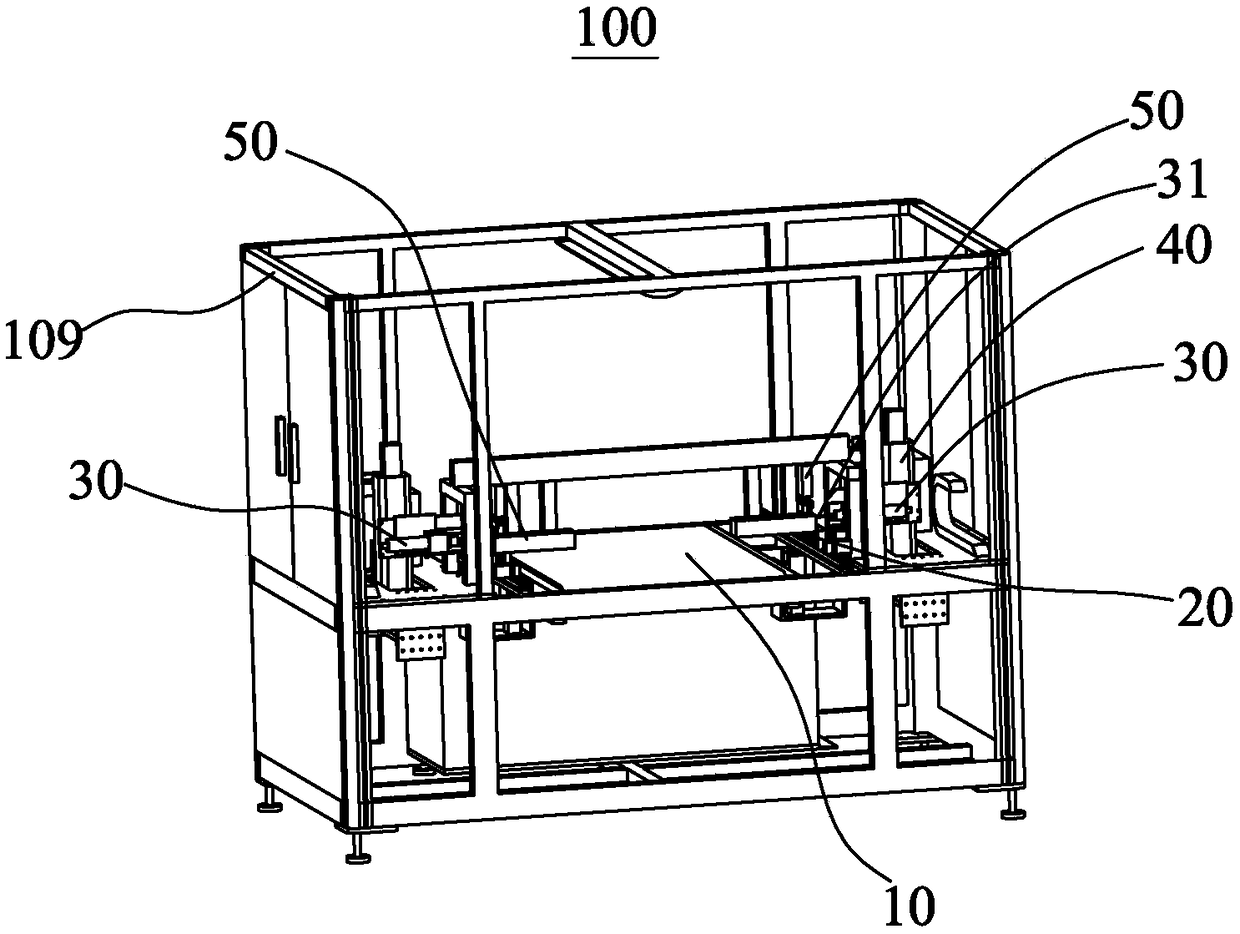

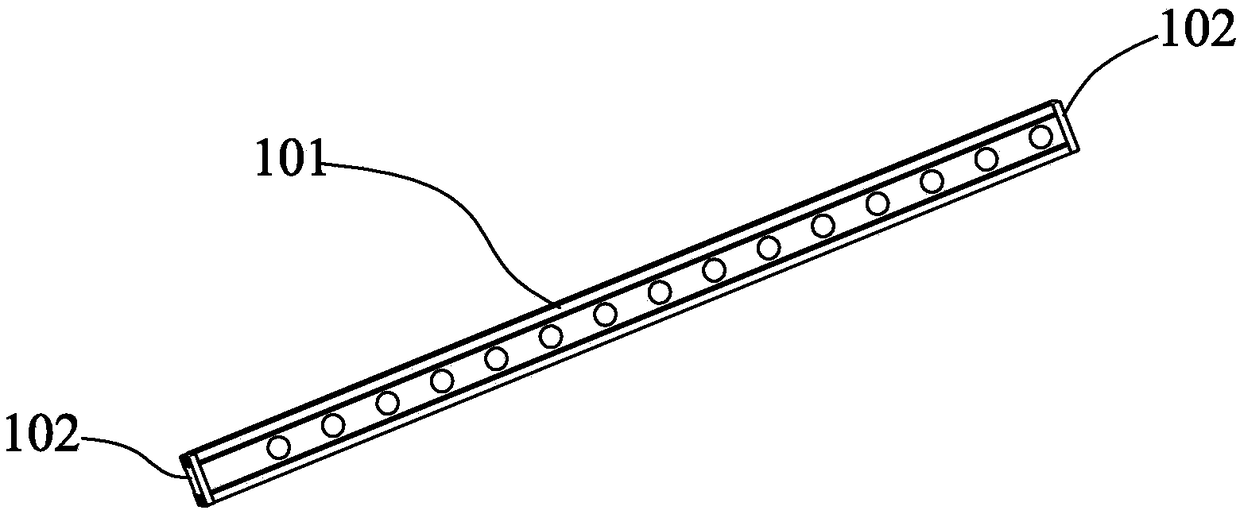

[0025] Please refer to figure 1 , figure 2 and image 3 , figure 1 It shows the flow of an automatic assembly process of a wall washer provided by the embodiment of the present invention, figure 2 Shows the wall washer automatic assembly equipment 100, image 3 The structure of the wall washer is shown. The wall washer includes a housing 101 and an end cover 102. The automatic assembly process of the wall washer includes the following steps:

[0026] S01, send the wall washer shell 101 to the position, that is: send the wall washer shell 101 to the screwing station, and the screwing station is equipped with a screwing device 100, and the screwing device 100 includes a feeding track 10. Two clamps 20, two screwdrivers 30, a drive assembly 40 and an end cap feeding assembly 50, each of the screwdrivers 30 has a screwdriver bit 31;

[0027] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap