Surface polishing machine for production of pvc pipe fittings

A technology for surface polishing and pipe fittings, which is applied to machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, grinding/polishing safety devices, etc. and other problems to achieve the effect of ensuring normal operation, convenient collection and treatment of residues, and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

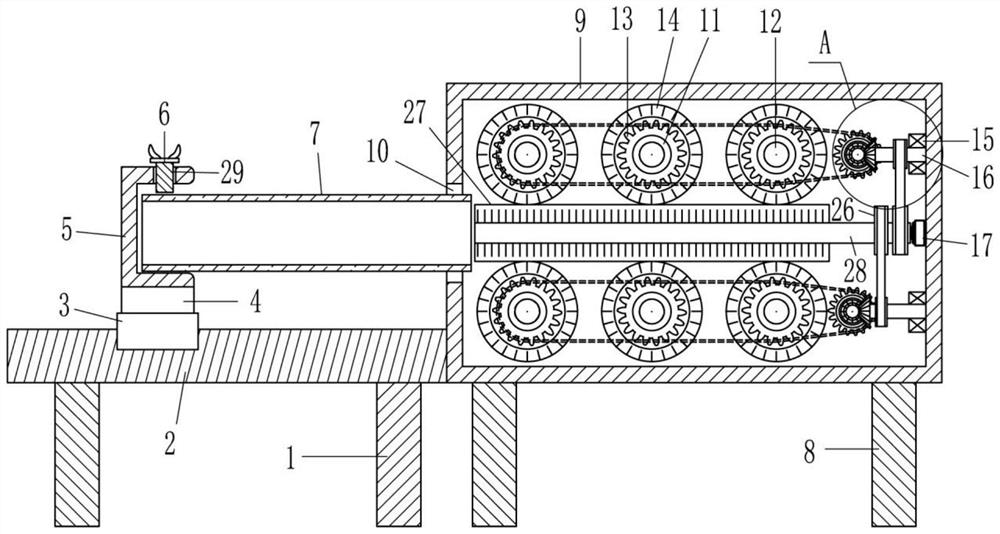

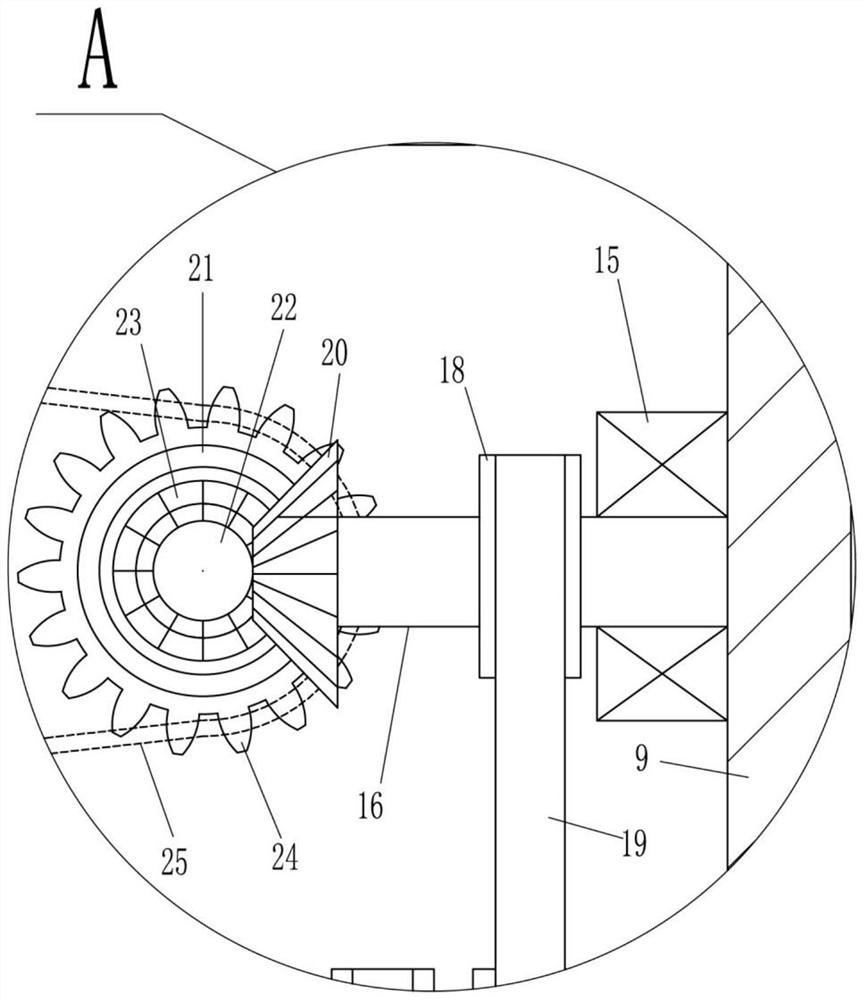

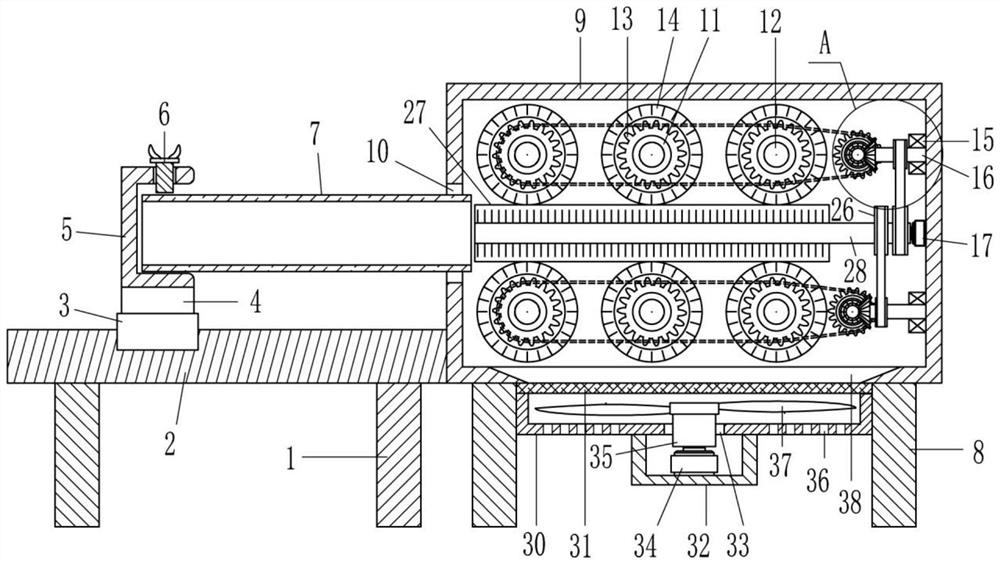

[0023] A surface polishing machine for the production of PVC pipe fittings, such as Figure 1-7 As shown, it includes a first support frame 1, a moving slide rail 2, a moving slider 3, a connecting block 4, an installation frame 5, butterfly bolts 6, a second support frame 8, a processing box 9, a first bearing seat 11, The first rotating shaft 12, the first gear 13, the first polishing brush 14, the second bearing seat 15, the second rotating shaft 16, the first motor 17, the first pulley 18, the flat belt 19, the first bevel gear 20, the third bearing Seat 21, third rotating shaft 22, second bevel gear 23, second gear 24, transmission chain 25, second pulley 26, second polishing brush 27 and fourth rotating shaft 28; moving slide rail 2 is fixedly connected to the first supporting frame 1 top, the processing box 9 is fixedly connected to the top of the second support frame 8, and the processing box 9 is provided with an entrance and exit 10; Connect; the first gear 13 and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap