Laminated slab reinforcing steel bar arranging frame

A technology of stacked boards and racks, applied in tool storage devices, manufacturing tools, etc., can solve the problems of different lengths of steel bars for stacked boards, no stacking racks, and a large proportion of stacked boards, so as to reduce potential safety hazards and improve safety. Accidents, the elimination of misuse, the effect of factory cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the technical solutions of the present invention will be described in further detail with reference to the accompanying drawings and specific implementations. It should be noted that in the absence of conflicts Below, the embodiments in the application and the features in the embodiments can be combined with each other. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

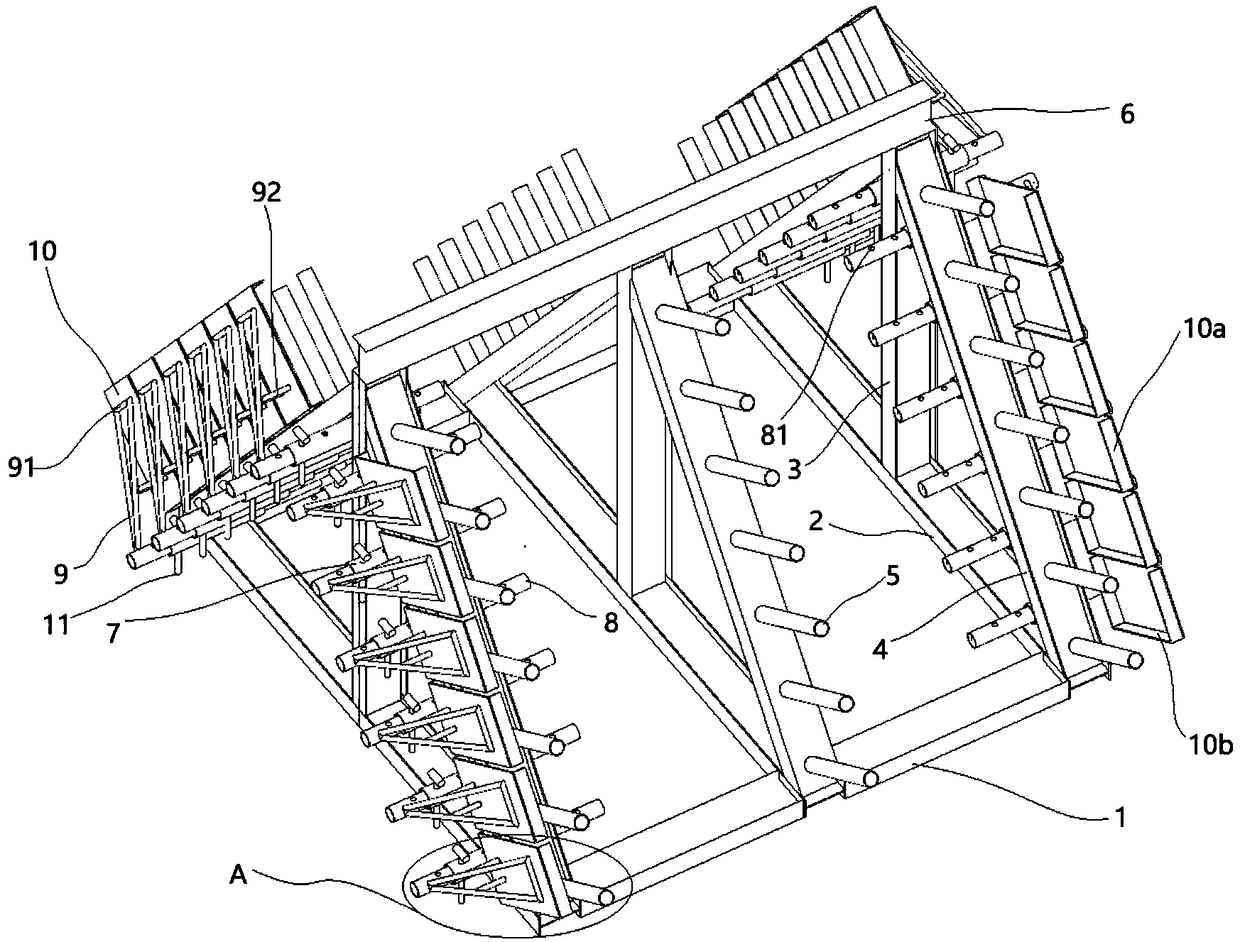

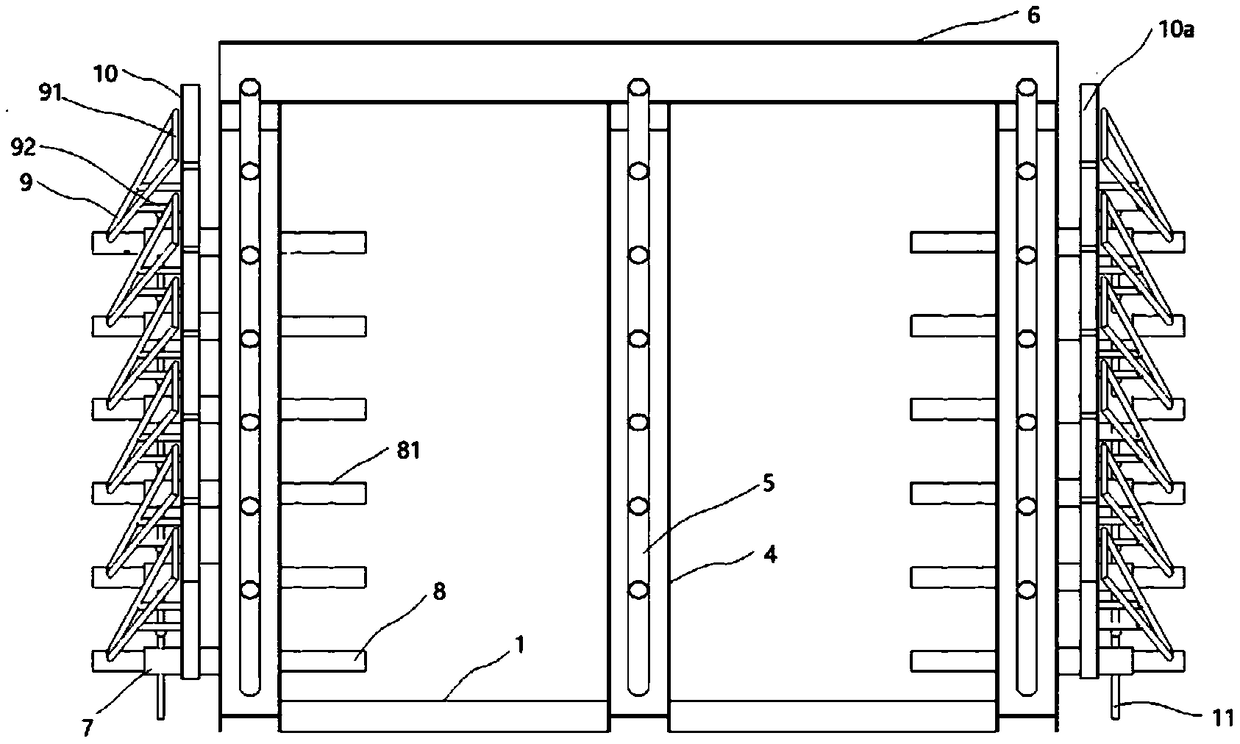

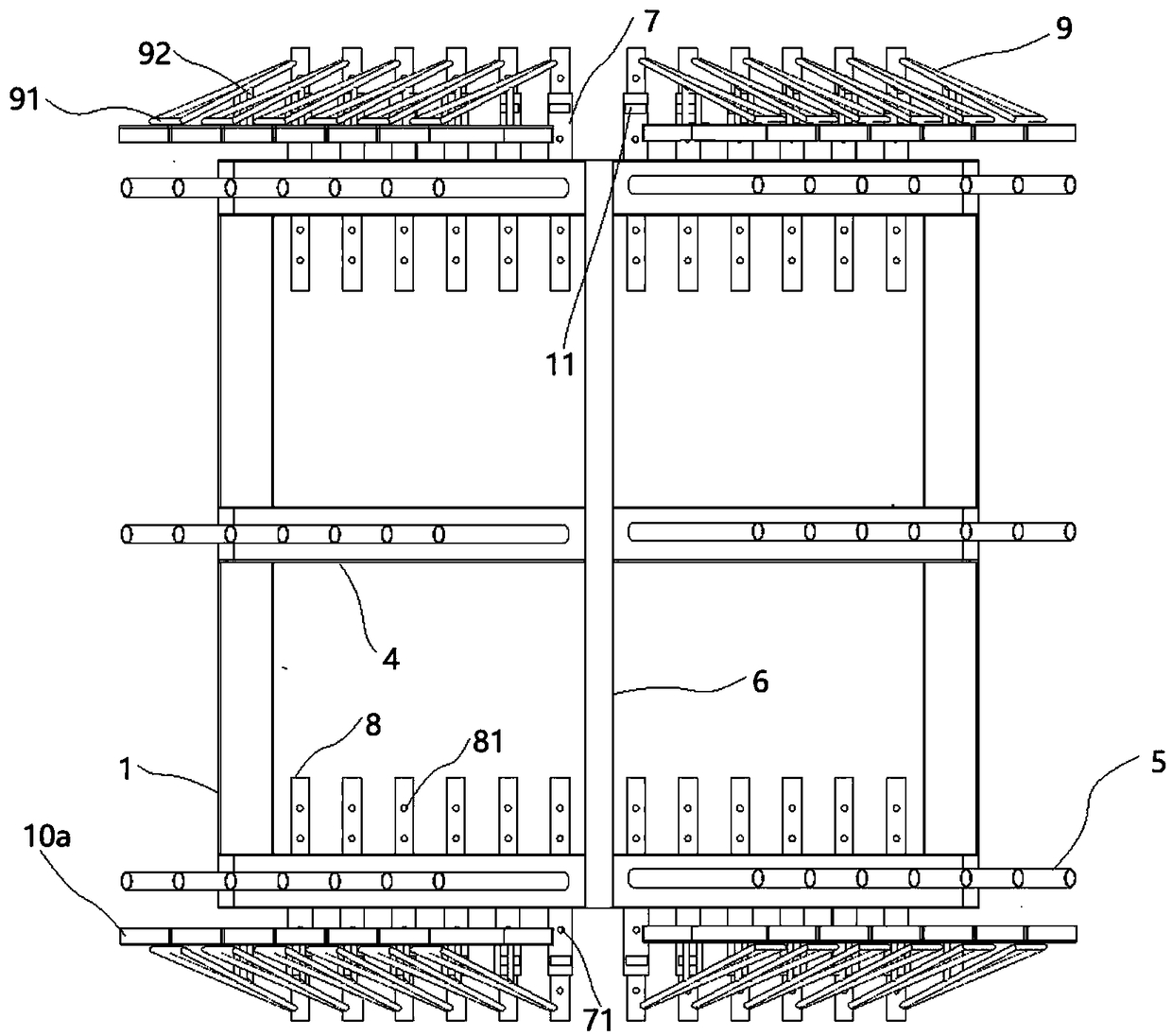

[0062] As attached figure 1 To the manual attached Figure 15 Shown is a laminated steel bar rack, the laminated steel bar includes a support base, the support base is symmetrically arranged by the lateral support 1 and a number of vertical supports arranged between the two lateral support 1 Piece 2 A rectangular frame body composed of two parts assembled and connected to each other, on which a numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com