Vertical type wood splitting machine

A wood splitter and vertical technology, which is applied in the direction of wood splitting devices, wood processing appliances, manufacturing tools, etc., can solve the problems of time-consuming and laborious operation, and achieve the effect of convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

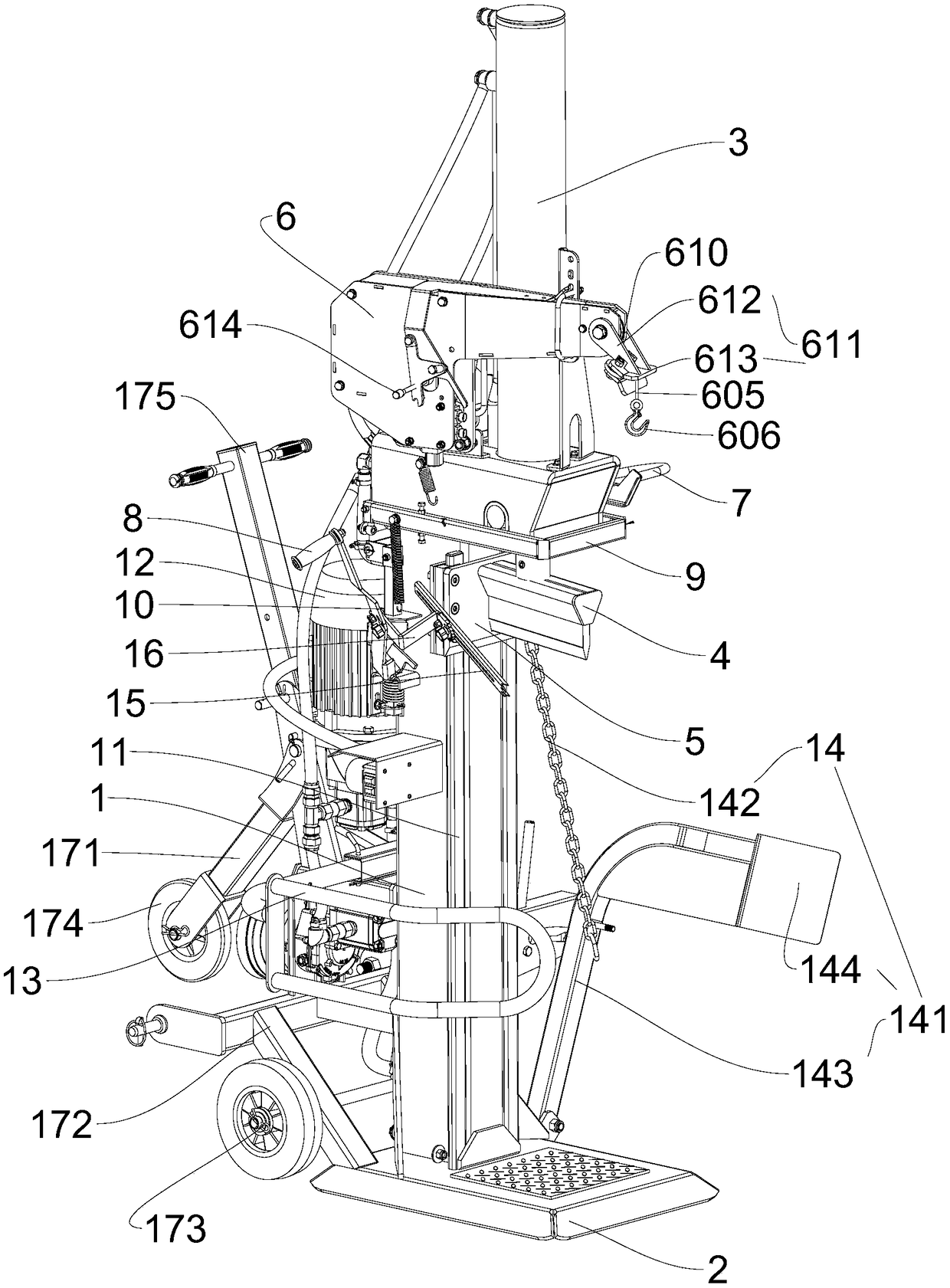

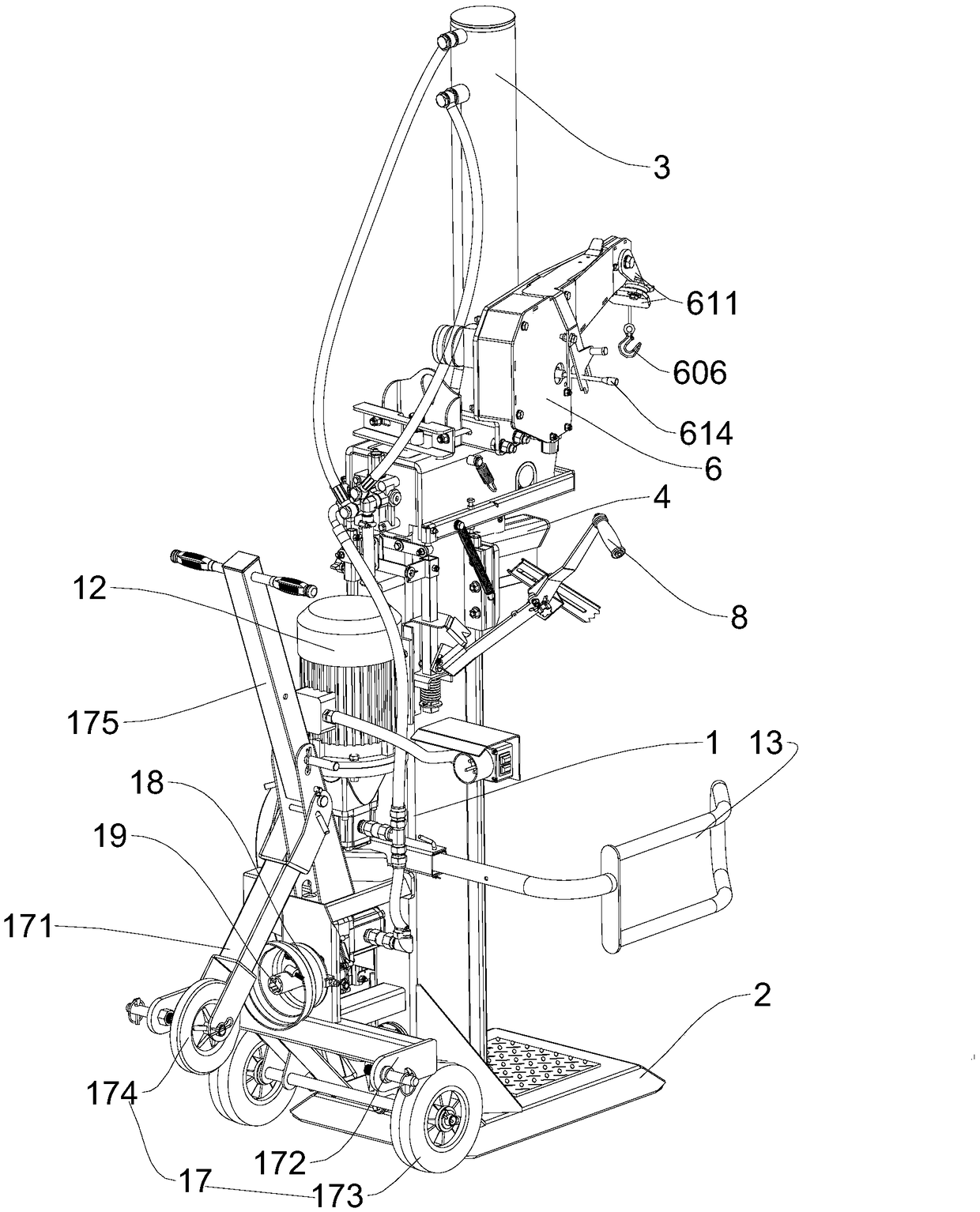

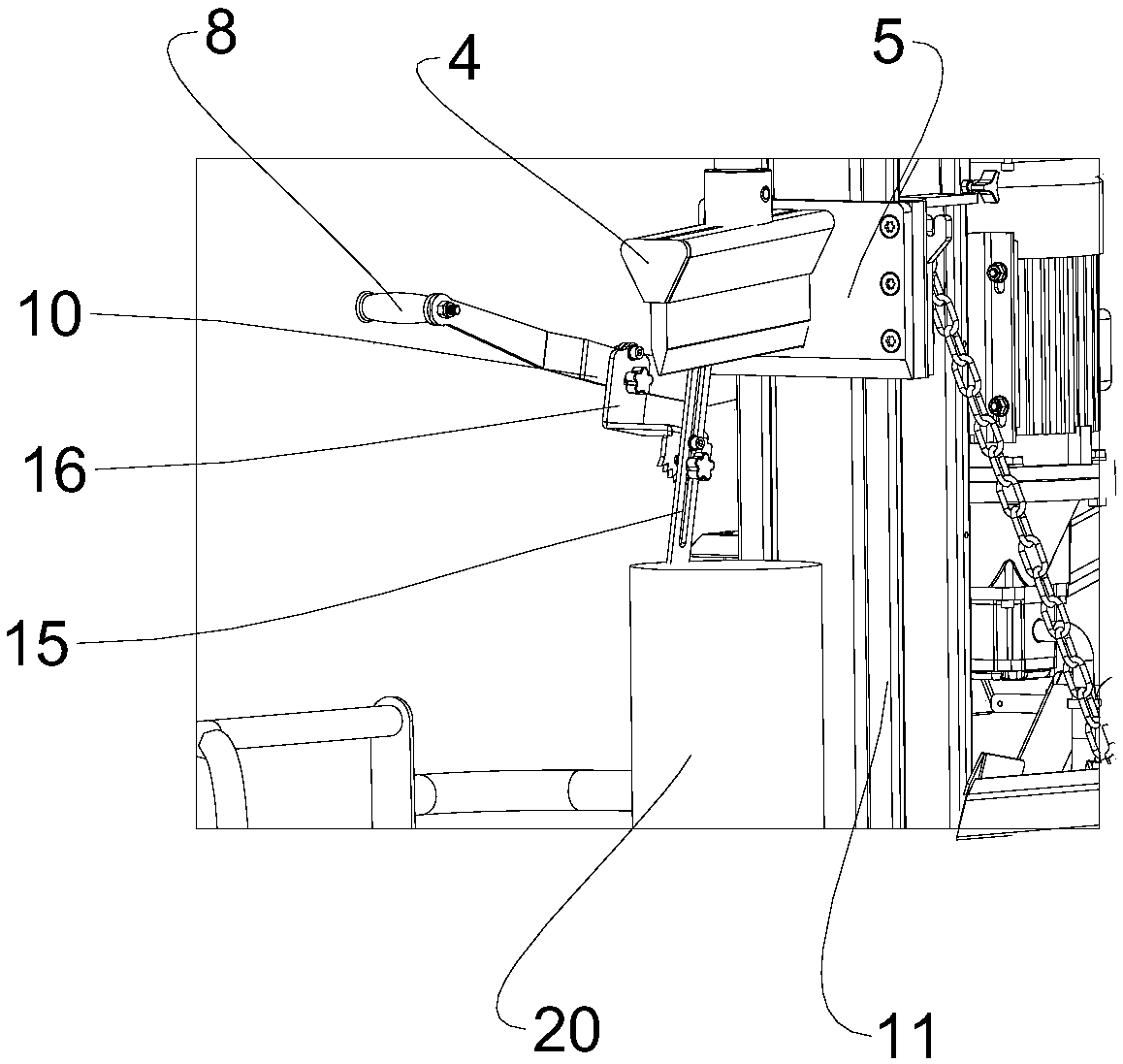

[0035] see Figure 1 to Figure 5 As shown, this embodiment provides a vertical wood splitter, including a fuselage 1 , a cutter body 4 , a wood splitting hydraulic cylinder 3 and a wood pulling mechanism 6 .

[0036] Wherein, fuselage 1 is the installation base of the whole equipment, and described fuselage 1 is set up vertically, and its bottom is provided with workbench 2, cooperates cutter body 4 to carry out splitting wood for convenience, and workbench 2 is arranged on described fuselage 1 side.

[0037] The wood splitting hydraulic cylinder 3 is the core of the wood splitting operation, and it can drive the cutter body 4 to perform the wood splitting operation. Generally speaking, log splitting hydraulic cylinder 3 comprises output rod and cylinder body, and described cylinder body comprises two oil cavities, and two oil cavities are separated by piston seal, and piston can slide in the cylinder body to drive the cylinder that is connected with piston. The output rod e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com