Polyethylene granulating method

A polyethylene and granulation technology, applied in the field of plastic processing, can solve the problems of insufficient cooling, sticking to the knife, long granulation time, etc., and achieve the effect of avoiding the breakage of the stirring blade, avoiding insufficient feeding, and simplifying feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

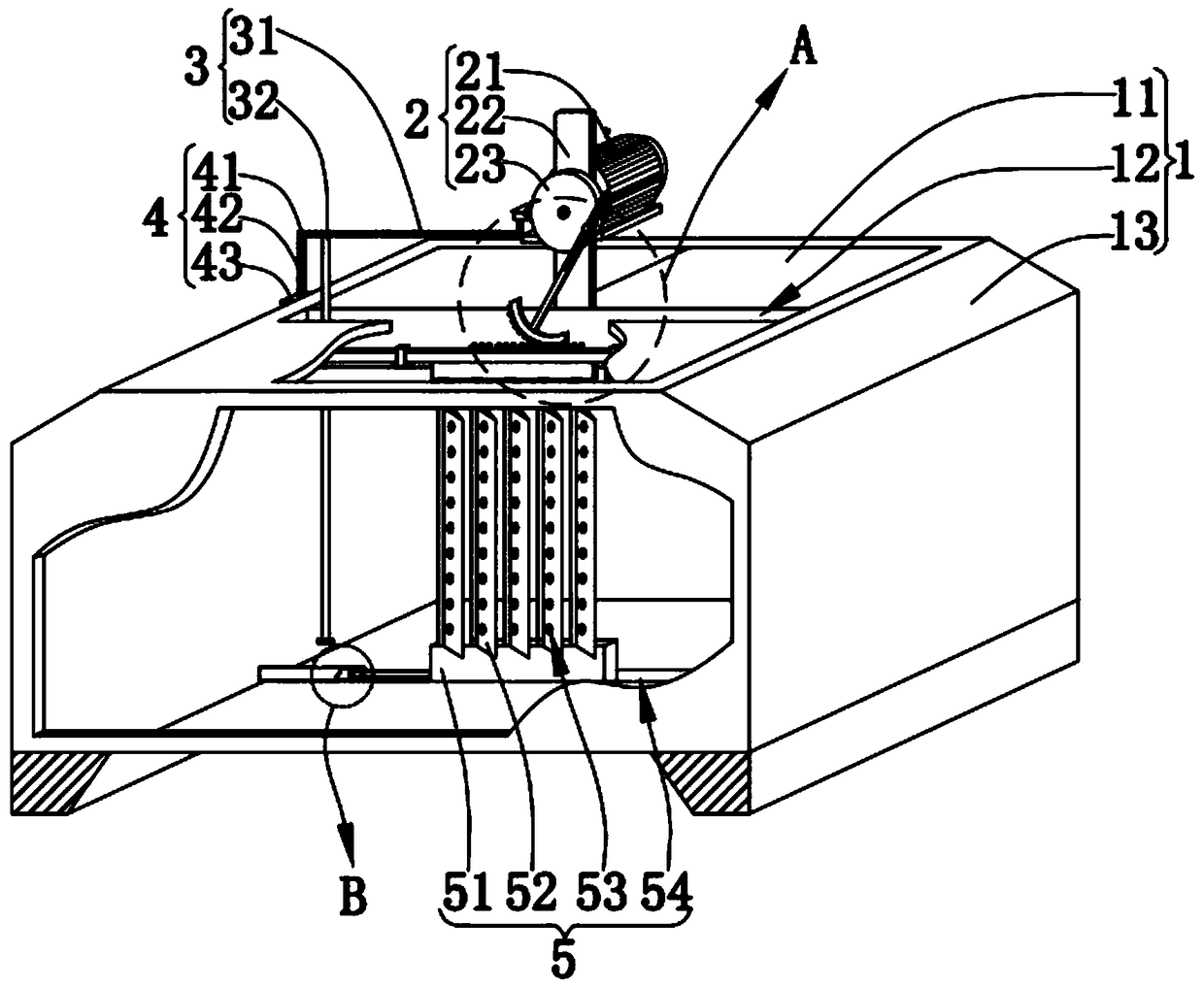

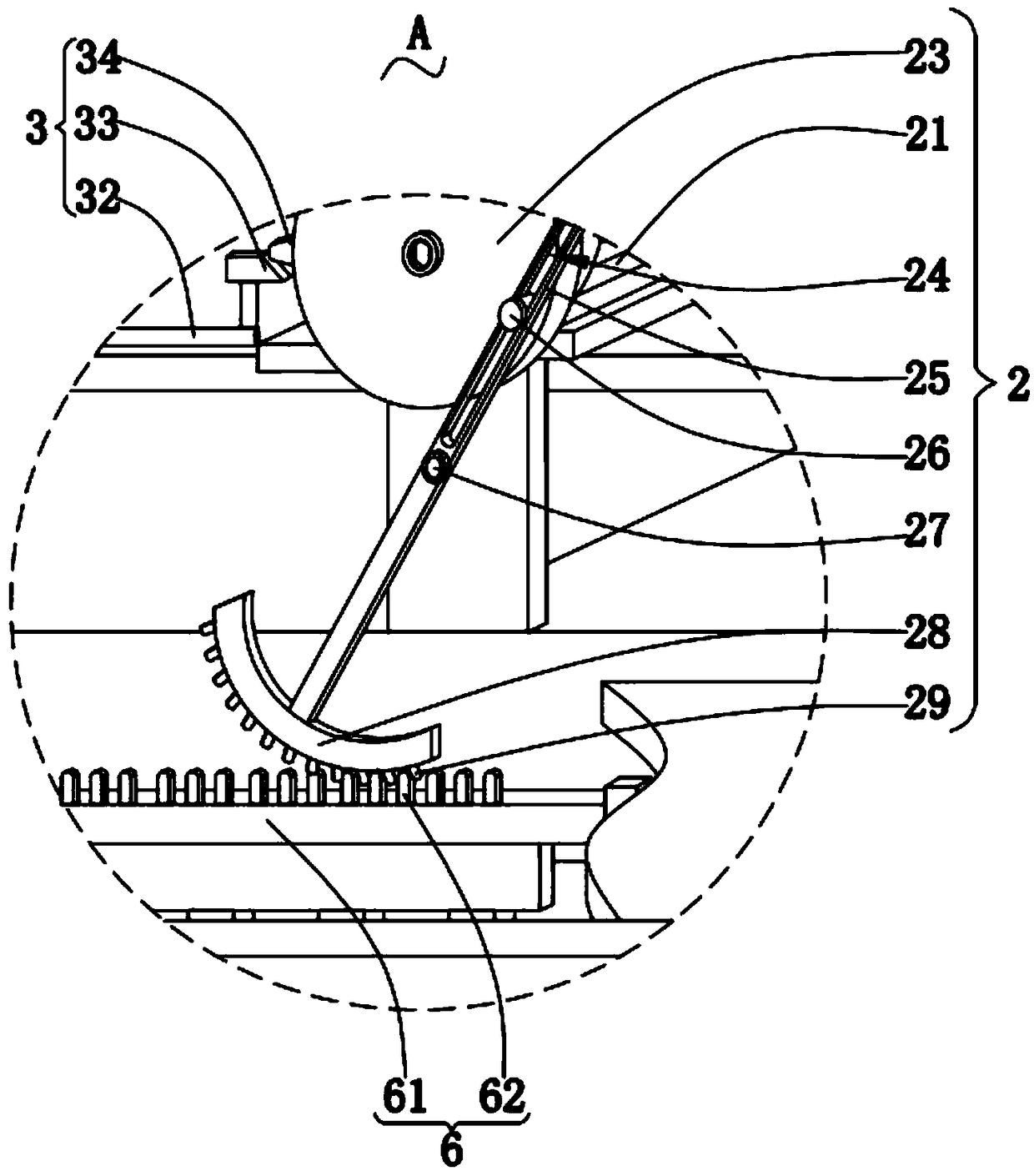

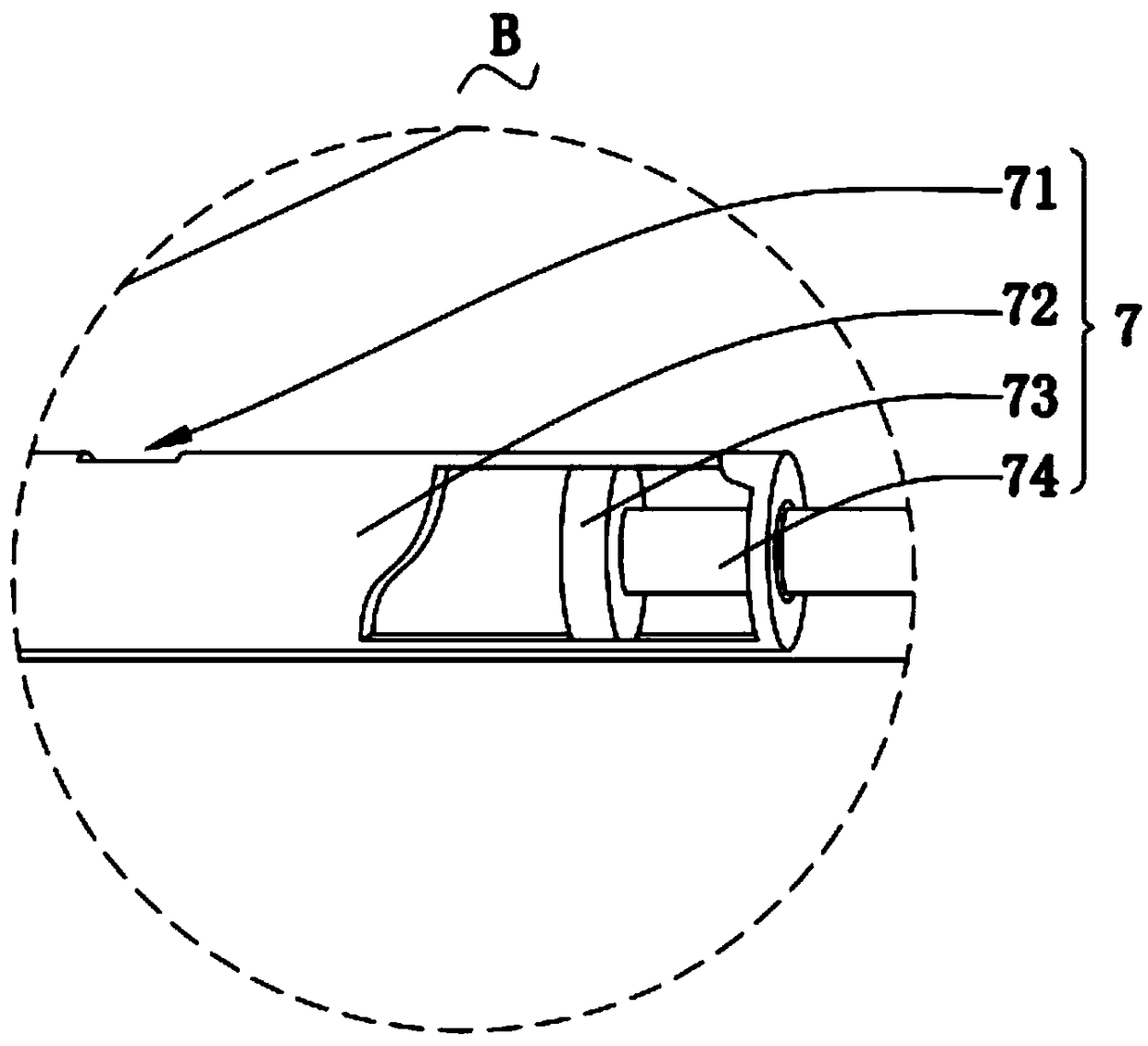

[0027] Such as figure 1 , figure 2 and image 3 Shown, a kind of polyethylene granulation method of the present invention, this method comprises the following steps:

[0028] S1, put the material into the granulation equipment for granulation;

[0029] S2, a cooling nozzle is installed at the outlet of the granulation equipment in S1, and the cooling nozzle is used to spray cold air to quickly cool the extruded strip polyethylene to improve the brittleness of the polyethylene, and then the cutter is used for cooling The final strip of polyethylene is cut to form polyethylene particles;

[0030] The granulation equipment used in this method includes a loading mechanism 1, a driving mechanism 2, a pressing mechanism 3, a reset mechanism 4, a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com