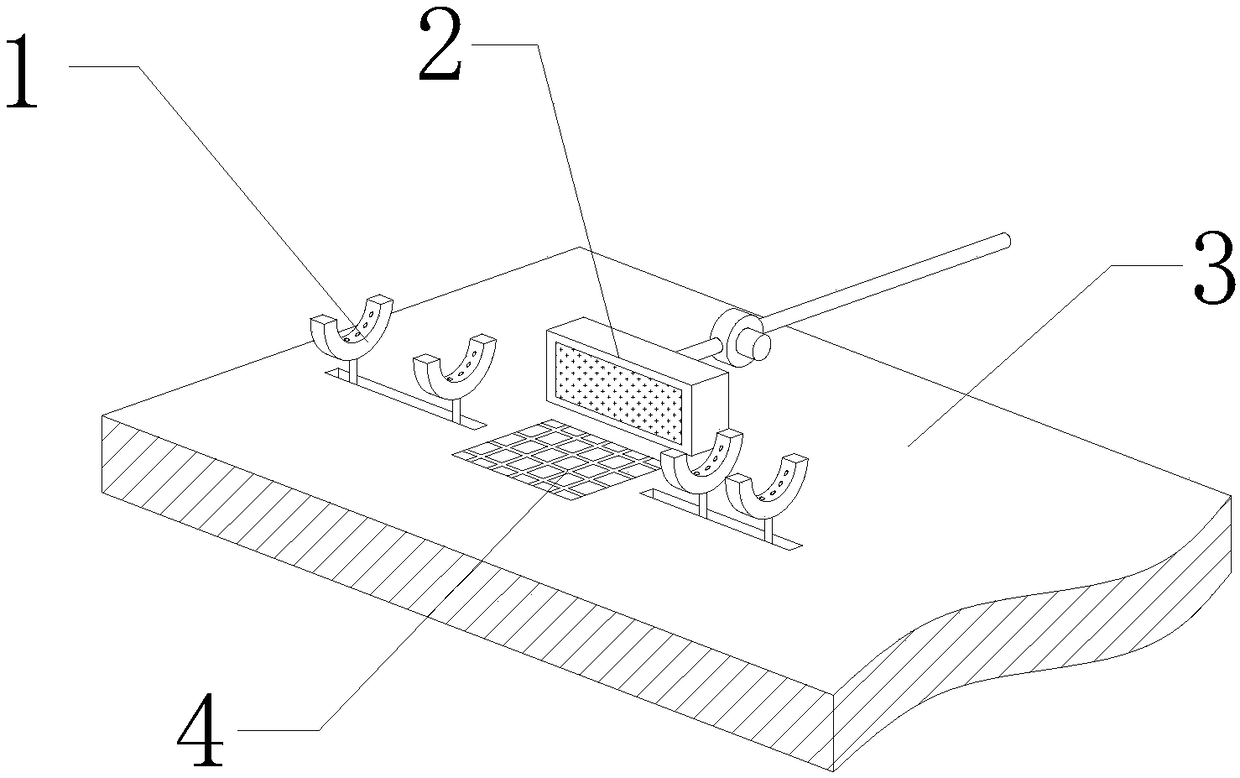

Softening device for plastic product bending machining

A softening device and technology for plastic products, which is applied in the field of rubber and plastic products, can solve the problems that the irritating gas cannot be discharged to the outside, affect the quality of plastic bending, and cannot achieve balanced support, etc., so as to facilitate heating and softening, improve quality, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

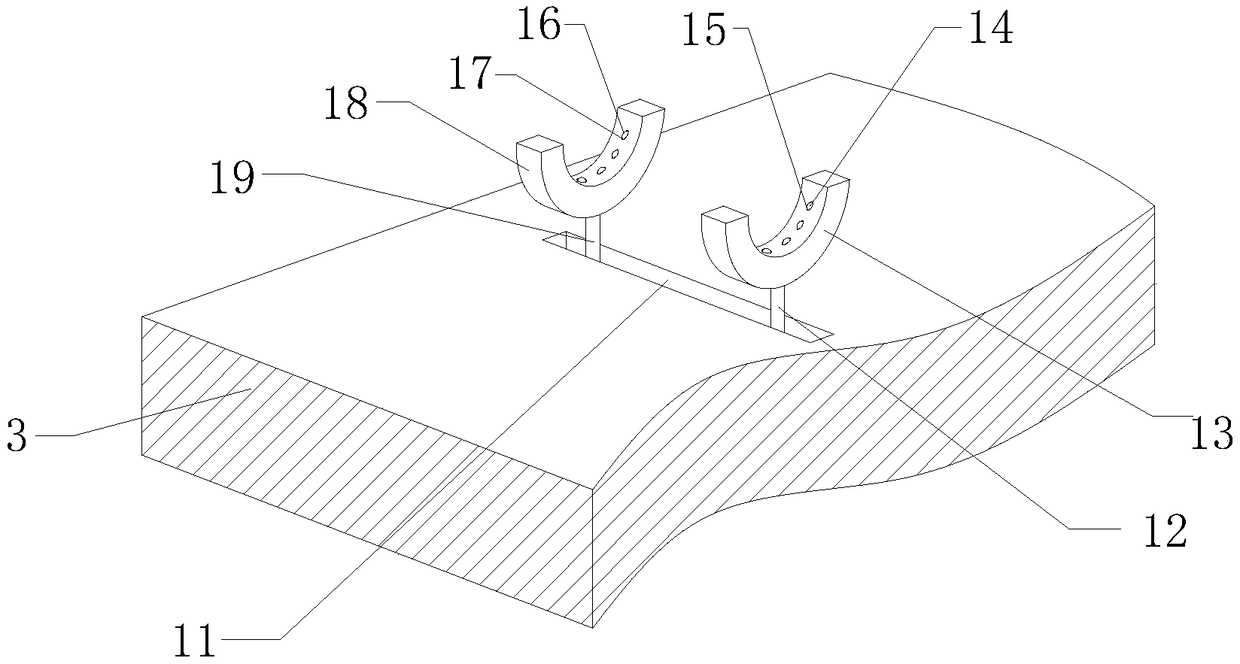

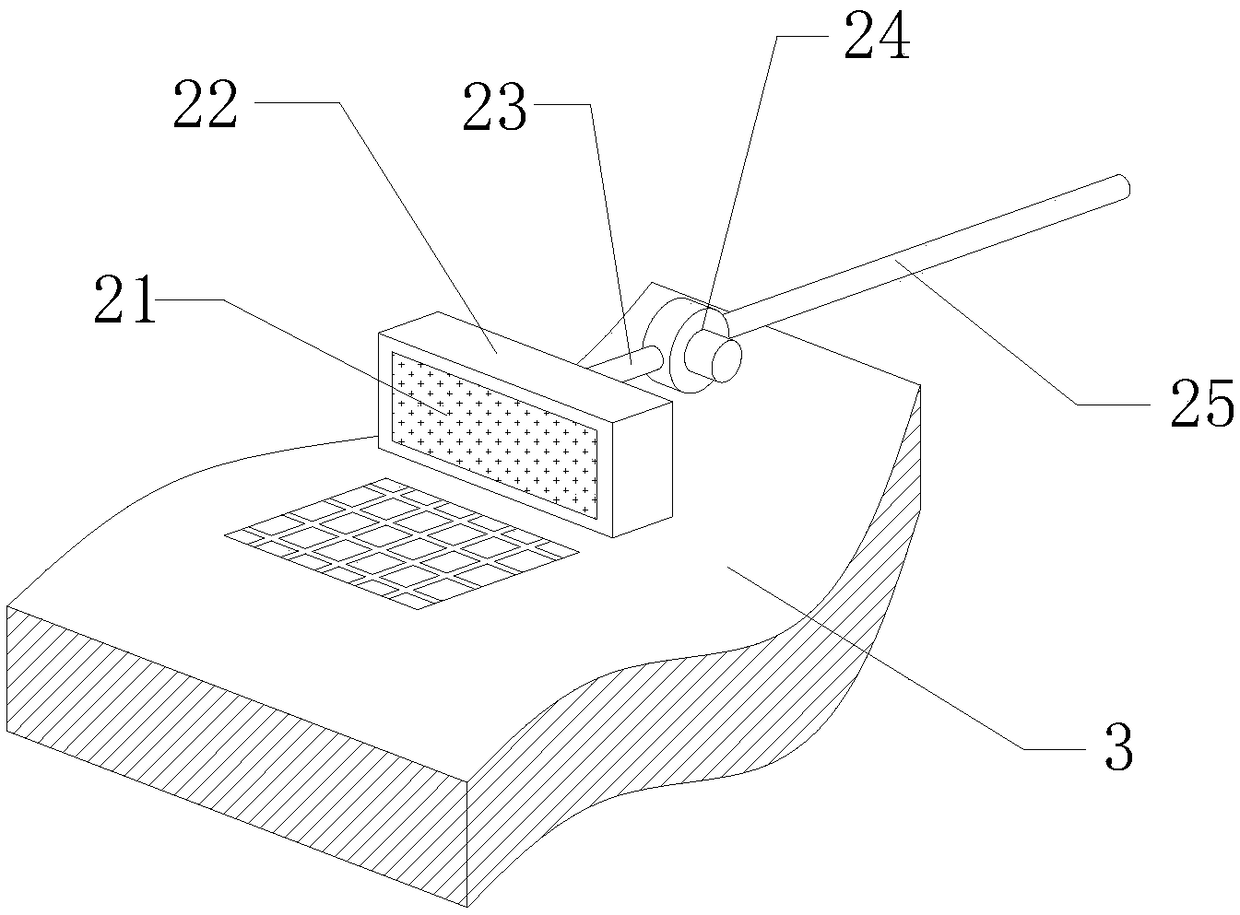

[0025] Specific implementation method: when in use, the staff places the plastic to be bent on two sets of arc pallets one 13 and two sets of arc pallets two 18, and then the staff pushes the arc pallet one 13 and the arc pallet two. Shape supporting plate two 18, and then arc supporting plate one 13 and arc supporting plate two 18 drive slide bar one 12 and slide bar two 19 to slide in the chute 11 respectively, when arc supporting plate one 13 and arc supporting plate When the position of the second 18 reaches the desired position, the staff stops pushing the arc supporting plate one 13 and the arc supporting plate two 18, and when the staff rotates the plastic to be bent, the ball one 14 and the ball two 16 are respectively in the ball groove one Roll in 15 and ball groove two 17, have reduced the frictional force between plastics to be bent and arc supporting plate one 13 and arc supporting plate two 18 with this, thereby realized the purpose of balanced bearing of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com