A kind of cross-connected double-layer plate assembly and its manufacturing method

A staggered, component-based technology, applied in covering/lining, construction, building construction, etc., can solve the problems of inconspicuous effect and poor versatility, and achieve the effects of saving time, simple installation, and reducing excessive weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

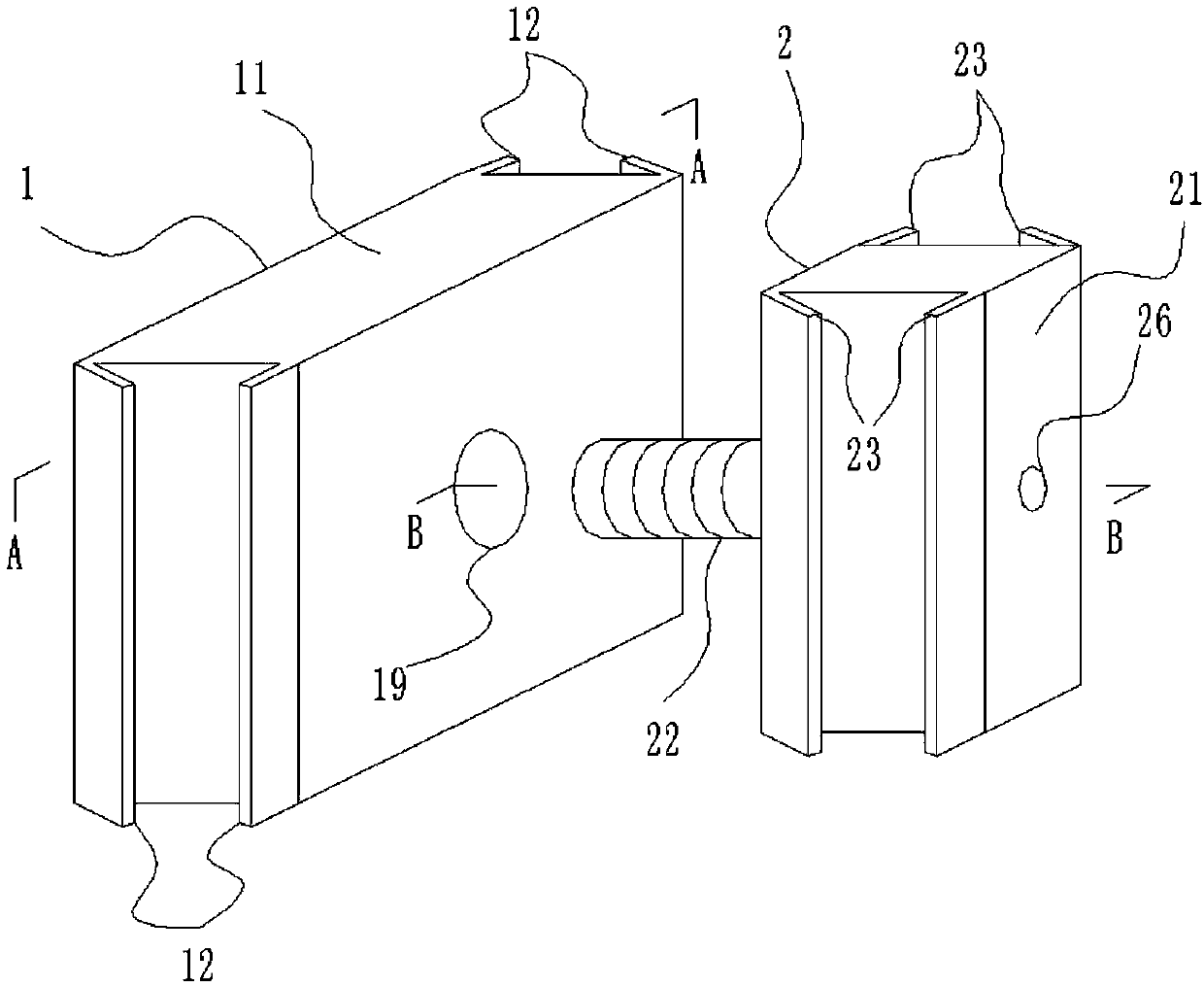

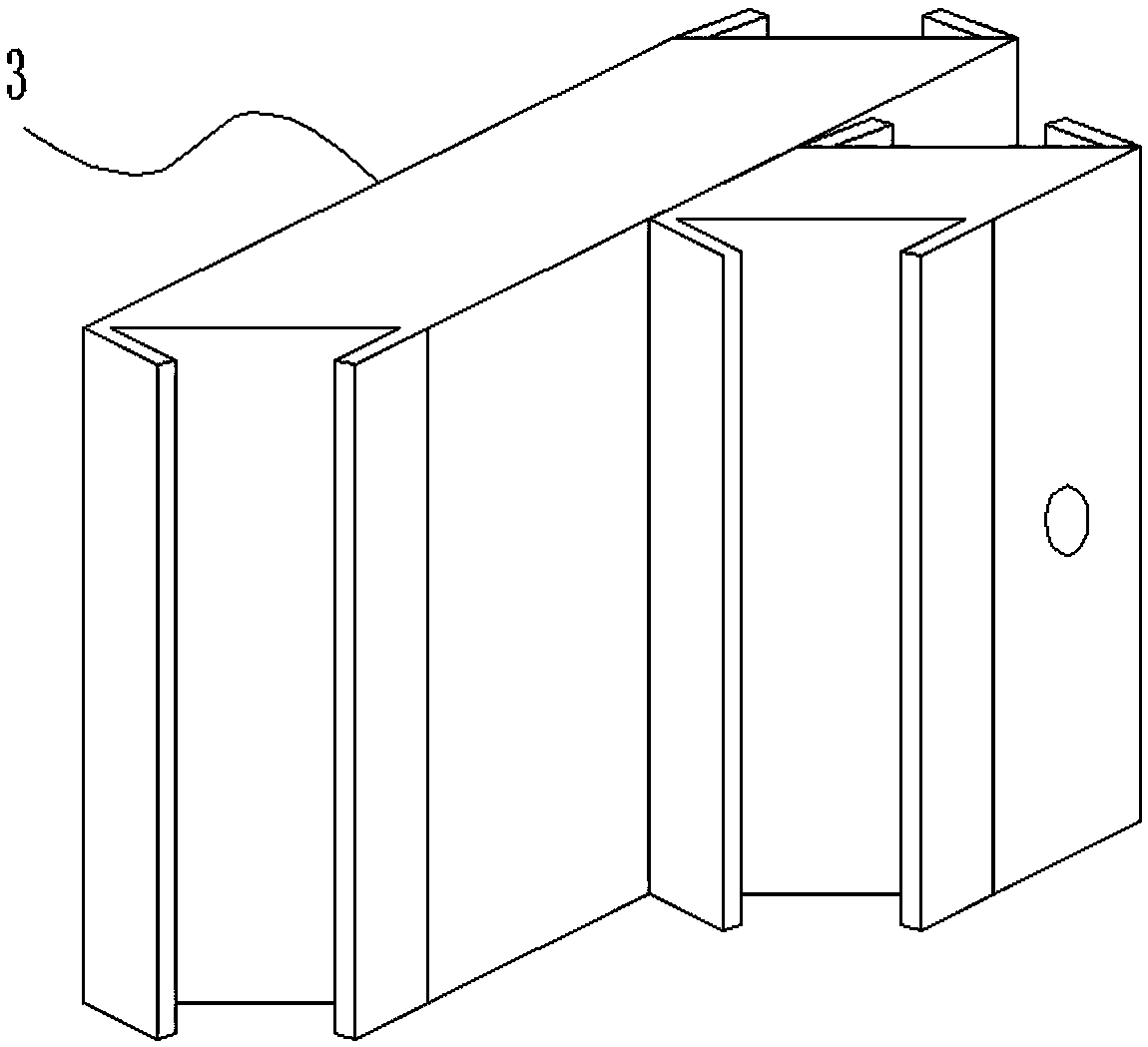

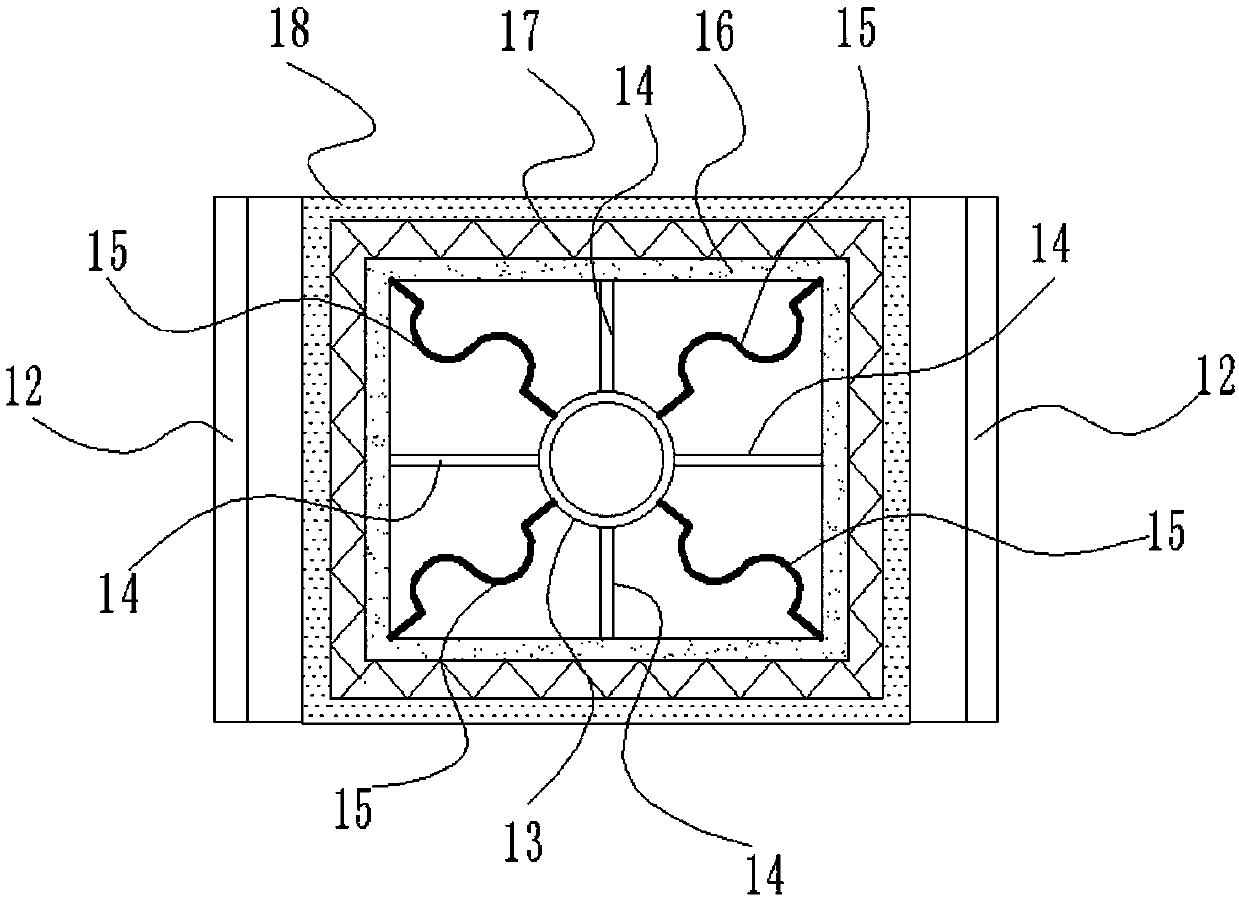

[0046] Such as Figure 1-2 As shown, a cross-connected double-layer panel assembly consists of a horizontal connection part 1 and a vertical connection part 2, such as image 3 As shown, the transverse connection part 1 includes a transverse box body 11, a block 12, a central tube 13, a straight rib 14, and an elastic reinforcement plate 15. The block 12 is strip-shaped, and there are four in total, which are paired in pairs and formed The figure of eight is arranged on the left and right opposite sides of the horizontal box body 11. The interior of the horizontal box body 11 is hollow, and the wall of the horizontal box body 11 has a three-layer structure. 18, wherein the alloy skeleton 17 is a staggered triangular structure, the central cylinder 13 is connected between the inner surfaces of the front and rear sides of the transverse box body 11, and the central cylinder 13 forms a central hole 19 on the front outer surface of the transverse box body 11 ,Such as Figure 9 A...

Embodiment 2

[0056] Such as Figure 1-2 As shown, a cross-connected double-layer panel assembly consists of a horizontal connection part 1 and a vertical connection part 2, such as image 3 As shown, the transverse connection part 1 includes a transverse box body 11, a block 12, a central tube 13, a straight rib 14, and an elastic reinforcement plate 15. The block 12 is strip-shaped, and there are four in total, which are paired in pairs and formed The figure of eight is arranged on the left and right opposite sides of the horizontal box body 11. The interior of the horizontal box body 11 is hollow, and the wall of the horizontal box body 11 has a three-layer structure. 18, wherein the alloy skeleton 17 is a staggered regular hexagonal honeycomb structure, the central cylinder 13 is connected between the inner surfaces of the front and rear sides of the transverse box body 11, and the central cylinder 13 is formed on the front outer surface of the transverse box body 11 Center hole one 19...

Embodiment 3

[0066] Such as Figure 1-2 As shown, a cross-connected double-layer panel assembly consists of a horizontal connection part 1 and a vertical connection part 2, such as Figure 4 As shown, the transverse connection part 1 includes a transverse box body 11, a block 12, a central tube 13, a straight rib 14, and an elastic reinforcement plate 15. The block 12 is strip-shaped, and there are four in total, which are paired in pairs and formed The figure of eight is arranged on the left and right opposite sides of the horizontal box body 11. The interior of the horizontal box body 11 is hollow, and the wall of the horizontal box body 11 has a three-layer structure. 18, wherein the alloy skeleton 17 is a staggered regular hexagonal honeycomb structure. The central cylinder 13 is connected between the inner surfaces of the front and rear sides of the transverse box body 11, and the central cylinder 13 forms a central hole 19 on the front outer surface of the transverse box body 11, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com