Control method for synchronous lifting of lifting hooks of double-lifting hook crane

A technology of synchronous lifting and control methods, applied in the directions of load hanging components, transportation and packaging, and can solve problems such as low use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

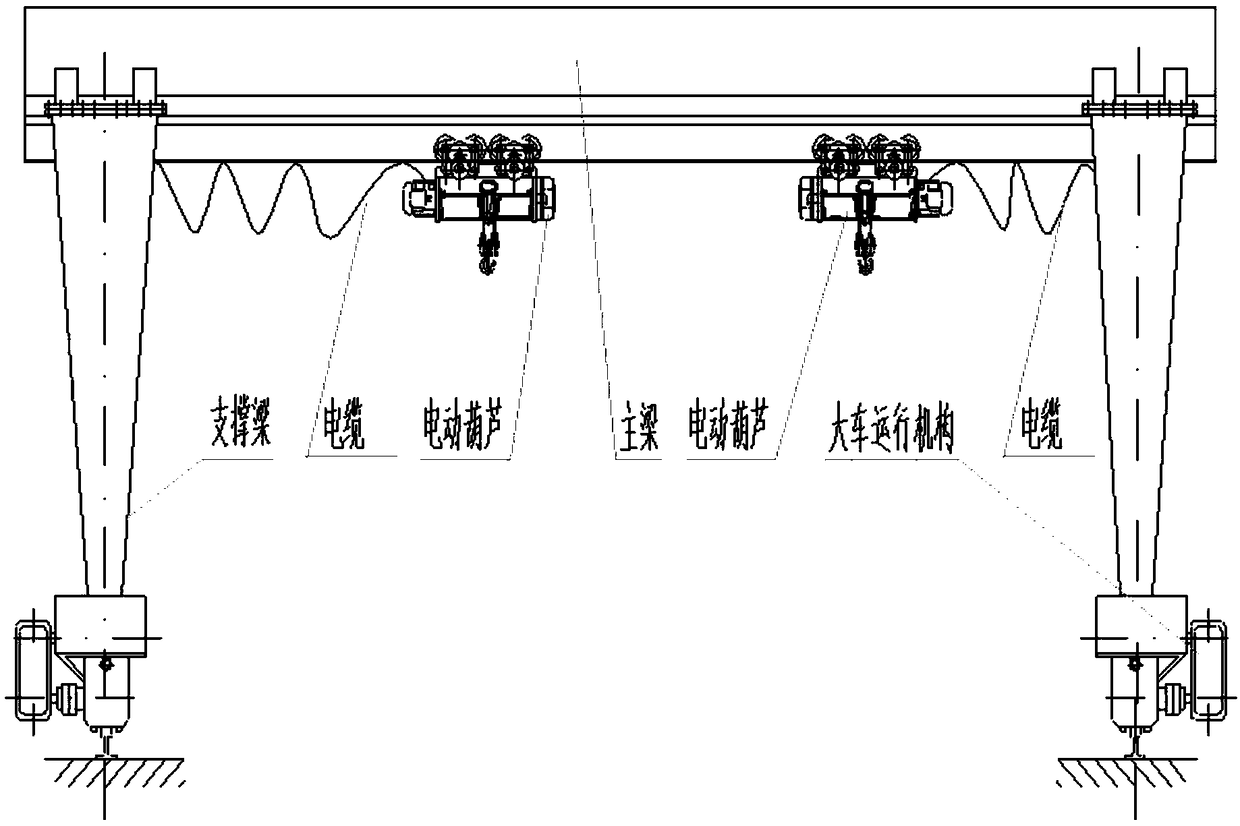

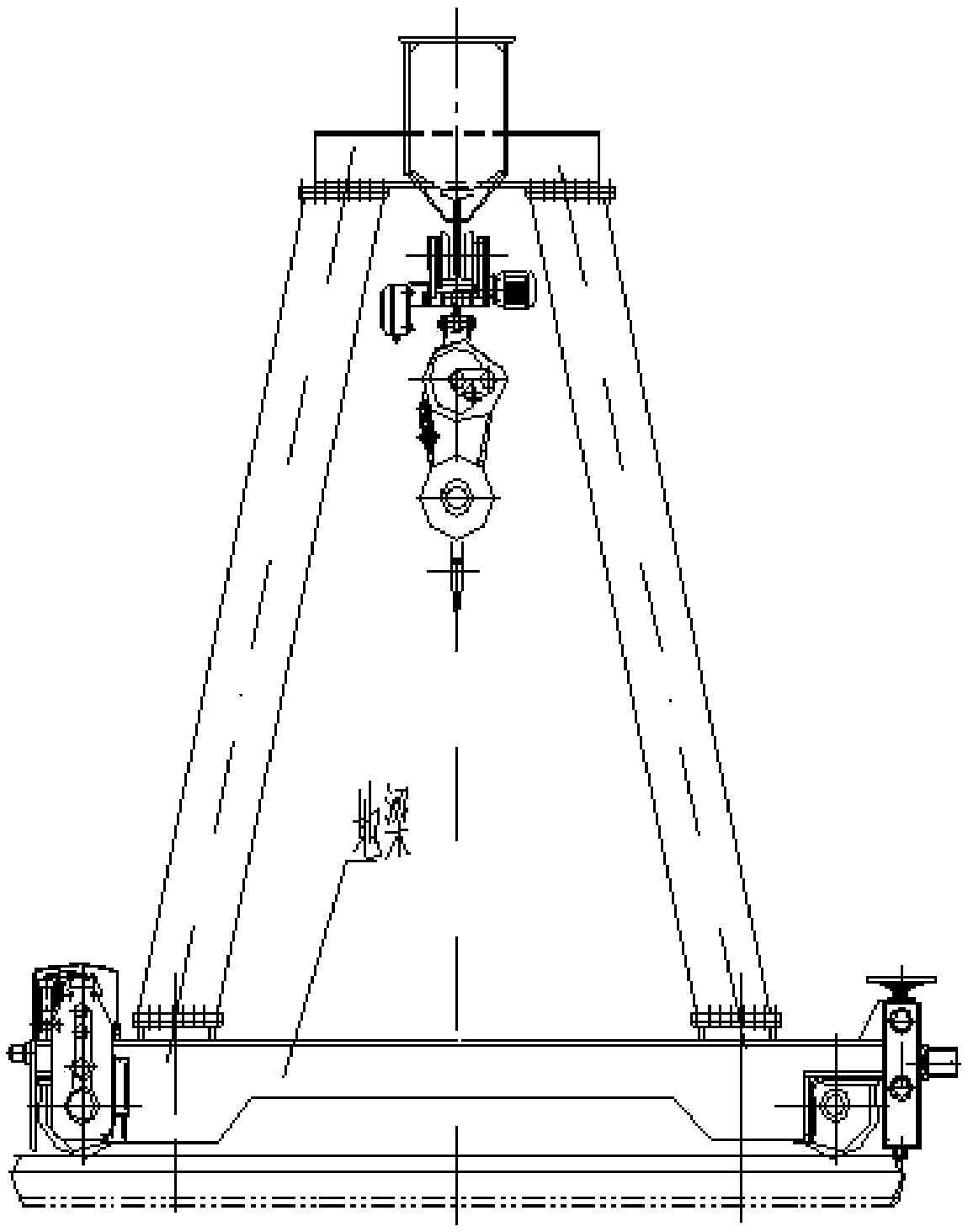

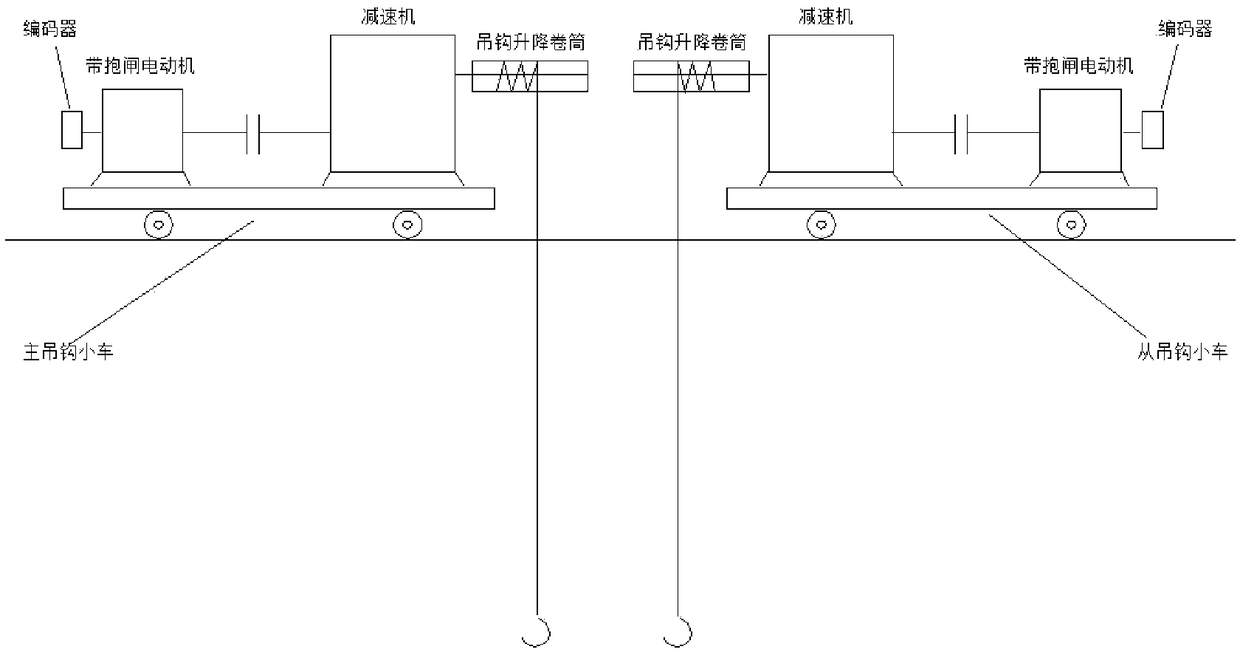

[0070] Such as Figure 1 to Figure 3 Shown, is the double hook driving structure of the present invention; Figure 4 with Figure 5 It is the synchronous lifting control program structure of double-hook driving master and slave hooks of the present invention.

[0071] For the commonly used double-hook gantry crane specially used for H-shaped steel grinding, since there is no automatic leveling function, its double hooks are prone to out-of-sync problems during long-distance lifting.

[0072] In order to realize the synchronous lifting of the special double hooks for H-beam grinding, it is necessary to install a lifting position det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com